Polyaniline electromagnetic shielding material based on cellulosic fibers and preparation method of electromagnetic shielding material

The technology of electromagnetic shielding material and cellulose fiber is applied in the field of polyaniline electromagnetic shielding material and its preparation, which can solve the problems of poor solubility and processing performance of polyaniline, unfavorable for market promotion and use, and expensive carbon nanotubes. To achieve the effect of low cost, regular arrangement and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

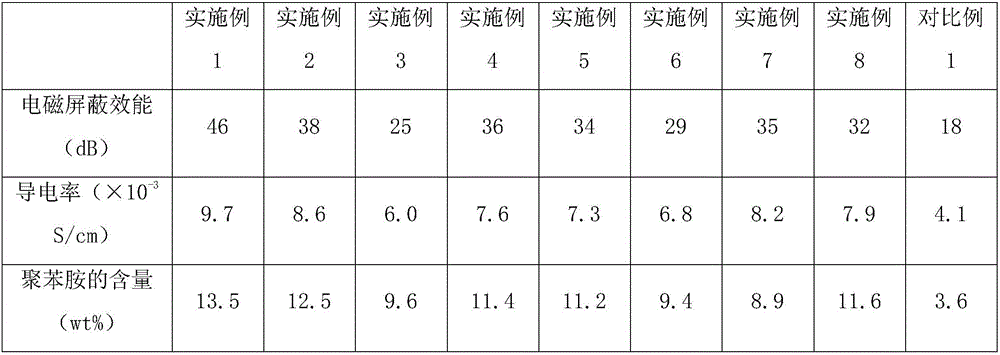

Examples

Embodiment 1

[0028] (1) Soak sugarcane powder and straw powder with a mass ratio of 1:1 in nitric acid solution, reflux at 110°C for 2.5h, add 3wt% sodium hydroxide solution, continue to reflux for 1.5h, cool to room temperature, and wash thoroughly , taken out, and fully dried at 50°C to obtain cellulose fibers.

[0029] (2) Mix 50-mesh 4g cellulose fibers with 5.8g aniline monomer, let stand for 30min, add 20ml of 1.5mol / L sulfuric acid solution, mix well to form solution A, cool to -10°C-0°C stand-by.

[0030] (3) Dissolve sodium persulfate with a mass ratio of 12.39g and potassium bicatalyte oxidant of 9.61g in 20ml of 1.5mol / L sulfuric acid solution, mix well to form solution B, and cool to -10°C-0°C stand-by.

[0031] (4) Slowly drop solution B into solution A, and oxidative polymerization reaction occurs at 0° C. for 4 hours to obtain a reaction product.

[0032] (5) The reaction product was filtered and washed with distilled water and ethanol respectively, and vacuum-dried at 60...

Embodiment 2

[0034] (1) Soak sugarcane powder and straw powder with a mass ratio of 2:1 in nitric acid solution, reflux at 110°C for 2.5h, add 3wt% sodium hydroxide solution, continue to reflux for 1.5h, cool to room temperature, and wash thoroughly , taken out, and fully dried at 50°C to obtain cellulose fibers.

[0035] (2) Mix 20-mesh 4g cellulose fibers with 5.8g aniline monomer, let stand for 30min, add 20ml of 1.5mol / L sulfuric acid solution, mix well to form solution A, cool to -10°C-0°C stand-by.

[0036] (3) Dissolve sodium persulfate with a mass ratio of 12.39g and potassium bicatalyte oxidant of 9.61g in 20ml of 1.5mol / L sulfuric acid solution, mix well to form solution B, and cool to -10°C-0°C stand-by.

[0037] (4) Slowly drop solution B into solution A, and oxidative polymerization reaction occurs at 0° C. for 4 hours to obtain a reaction product.

[0038] (5) The reaction product was filtered and washed with distilled water and ethanol respectively, and vacuum-dried at 60...

Embodiment 3

[0040](1) Soak sugarcane powder and straw powder with a mass ratio of 1.5:1 in nitric acid solution, reflux at 110°C for 2.5h, add 3wt% sodium hydroxide solution, continue to reflux for 1.5h, cool to room temperature, and wash thoroughly , taken out, and fully dried at 50°C to obtain cellulose fibers.

[0041] (2) Mix 150-mesh 4g cellulose fibers with 5.8g aniline monomer, let stand for 30min, add 20ml of 1.5mol / L dodecylbenzenesulfonic acid solution, mix well to form solution A, and cool to -10°C-0°C for use.

[0042] (3) be that the sodium persulfate of 12.39g and the potassium dicatalyst oxidant of 9.61g are dissolved in the dodecylbenzenesulfonic acid solution of 1.5mol / L of 20ml by mass ratio, mix, form solution B, be cooled to -10°C-0°C for use.

[0043] (4) The solution B was slowly dropped into the solution A, and an oxidative polymerization reaction occurred at 0°C for a reaction time of 4 hours to obtain a reaction product.

[0044] (5) The reaction product was fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com