A microbe decomposing agent for livestock and poultry manure waste and a preparing method and applications thereof

A microbial decomposing agent and waste technology, which is applied in the preparation and application of organic fertilizers, organic fertilizers, etc., can solve the problem of poor stability of decomposing effect of livestock and poultry manure waste, failure to fully consider the ability of bacteria to produce enzymes, bacteria Unreasonable combination with strains and other problems, to achieve the effect of prolonging the shelf life of products, good promotion and use value, and beneficial to plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

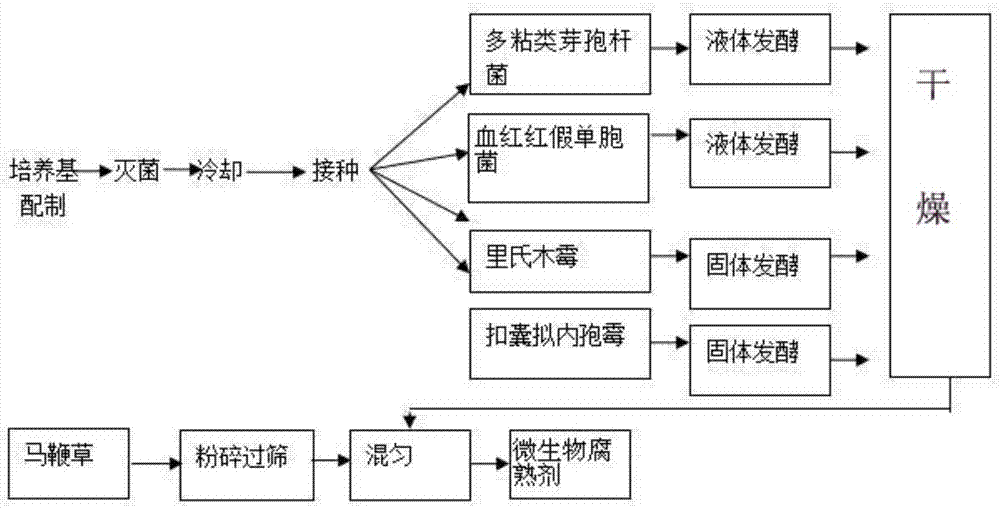

Method used

Image

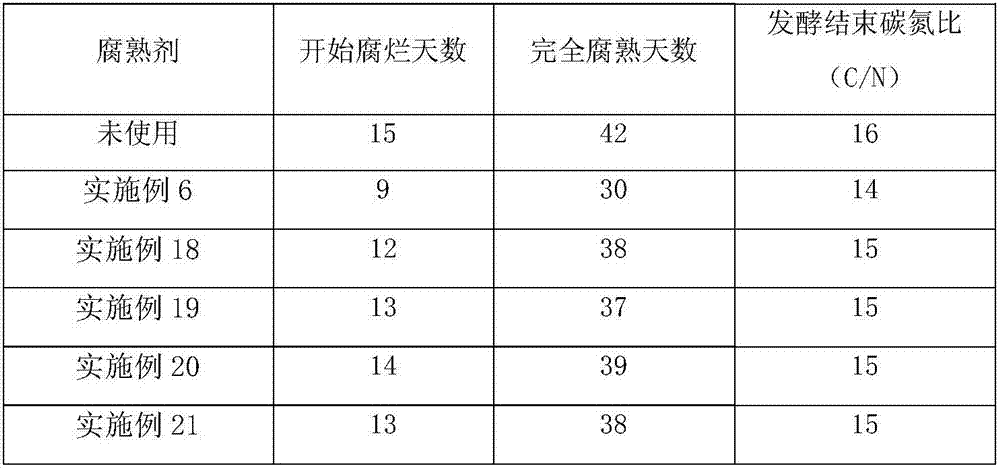

Examples

Embodiment 1

[0031] Example 1 Preparation of Paenibacillus polymyxa powder:

[0032] A. Transfer the freeze-dried Paenibacillus polymyxa strains to the prepared test tube slope in a sterile environment, control the temperature at 35°C, cultivate for 36 hours, then transfer to eggplant-shaped bottles for 30 hours, check After confirming that there is no miscellaneous bacteria, it is used to inoculate the fermenter; the concentration of each component of the medium in the eggplant-shaped bottle is as follows: tryptone 8-10g / L, yeast extract 3-5g / L, sodium chloride 3-5g / L, solvent for water;

[0033] B. Preparation of medium material: The medium material in the fermenter needs to be proportioned according to the ratio of 0.5g of glucose, 0.5g of beef extract, 0.5g of peptone and 0.5g of sodium chloride per liter of water, mixed and dissolved in water, and transported to inside the fermenter;

[0034] C. Sterilization and cooling: put steam into the fermenter, start stirring, keep warm for 3...

Embodiment 2

[0040] Example 2 Preparation of Rhodopseudomonas rhodopsin powder:

[0041] A. Transfer the freeze-dried Rhodopseudomonas strains to the pre-prepared test tube slope in a sterile environment, control the temperature at 30-35°C, cultivate for 36 hours, and then transfer to an eggplant bottle for 32 hours. After checking and confirming that there is no miscellaneous bacteria, it is used for fermenter inoculation; the concentration of each component of the medium in the eggplant-shaped bottle is as follows: tryptone 8-10g / L, yeast extract 3-5g / L, sodium chloride 3-5g / L , the solvent is water;

[0042] B, prepare culture medium material: culture medium material in the fermenter needs to be configured with the proportioning of glucose 5g, yeast extract 2g, peptone 1g, soybean meal powder 5g and potassium dihydrogen phosphate 0.5g according to every liter of water, so that it is dissolved in water, into the fermenter;

[0043] C. Sterilization and cooling: put steam into the ferme...

Embodiment 3

[0049] Example 3 Preparation of Trichoderma reesei powder:

[0050] A. Preparation of culture medium mixture: according to the proportioning by mass percentage, the proportioning of the materials is 70% of bran, 15% of soybean meal, and 15% of corn flour. 0.5% magnesium sulfate heptahydrate, 3.5% iron sulfate, 0.2% potassium dihydrogen phosphate, and distilled water to make the water content reach 60%, and the trace elements are dissolved with water and added together with water ;

[0051] B. Sterilization and cooling: heat up the medium mixture material obtained in the process of A to 121°C, keep the temperature at 121°C and keep the pressure for 1 hour, then start to ventilate and cool to the interlayer of the fermentation tank, and cool to 30°C;

[0052] C, inoculation: after mixing Trichoderma reesei spore powder and 1 kg flour, inoculate on the culture medium mixture material in the fermentation tank after the high temperature and high pressure sterilization that obtains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com