High dielectric constant nano-filtration composite film and preparation method thereof

A high dielectric constant, composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reduced separation performance, reduced membrane service life, and restrictions on the application of water treatment, to reduce The effect of electric field loss, prolonging service life, and avoiding concentration polarization phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A high dielectric constant nanofiltration composite membrane, comprising a porous base membrane and a polyester amine active layer attached thereon, wherein the porous base membrane includes calcium copper titanate and polyvinylidene fluoride, and the polyester amine active layer includes m-phenylene difluoride Amine, p-phenylenediamine polyamine monomer.

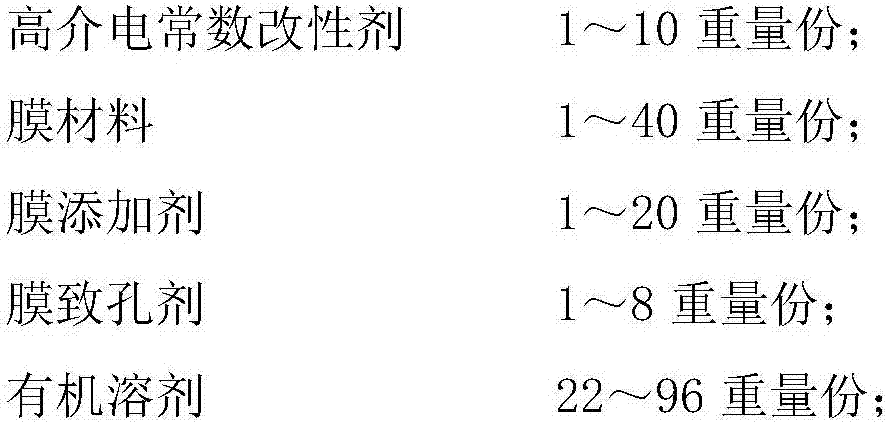

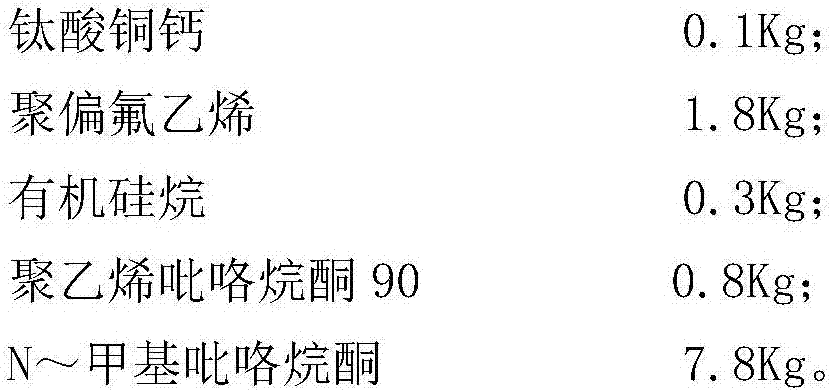

[0044] The composition and weight of the raw material of the porous base membrane are:

[0045]

[0046] The aqueous solution component and weight thereof of the raw material of polyester amine active layer are:

[0047]

[0048] In order to control the acid-base balance to promote the reaction, camphorsulfonic acid is added to the aqueous solution as a pH regulator, which can make the polyamine aqueous solution adhere better to the surface of the porous substrate.

[0049] A high dielectric constant nanofiltration composite membrane, the preparation method of which is:

[0050] 1) Modifier preparation: vacuu...

Embodiment 2

[0061] A high dielectric constant nanofiltration composite membrane, comprising a porous base membrane and a polyester amine active layer attached thereon, wherein the porous base membrane includes barium titanate, titanium dioxide and polyvinylidene fluoride, and the polyester amine active layer includes p-phenylene Ethylenediamine, piperazine polyamine monomer.

[0062] The components of the raw materials of the nanofiltration composite membrane and their weight and number ratios are:

[0063]

[0064] The aqueous solution component and weight thereof of the raw material of polyester amine active layer are:

[0065]

[0066]

[0067] A high dielectric constant nanofiltration composite membrane, the preparation method of which is:

[0068] 1) Modifier preparation: the mixture of barium titanate and titanium dioxide was vacuum-dried at 150° C. for 24 hours, and the dried mixture of barium titanate and titanium dioxide was collected.

[0069] 2) Preparation of castin...

Embodiment 3

[0079] A high dielectric constant nanofiltration composite membrane, comprising a porous base membrane and a polyester amine active layer attached thereto, wherein the porous base membrane includes titanium dioxide, barium strontium titanate and polyvinylidene fluoride, and the polyester amine active layer includes homogeneous Benzene triamine polyamine monomer.

[0080] The components of the raw materials of the nanofiltration composite membrane and their weight and number ratios are:

[0081]

[0082]

[0083] The aqueous solution component and weight thereof of the raw material of polyester amine active layer are:

[0084]

[0085] A high dielectric constant nanofiltration composite membrane, the preparation method of which is:

[0086] 1) Modifier preparation: titanium dioxide and barium strontium titanate were vacuum-dried at 150° C. for 24 hours, and the dried calcium copper titanate was collected.

[0087] 2) Preparation of casting solution: Take 0.8Kg of tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com