Bone collagen propeptide ammonia sugar pills for increasing bone density and preparation method of bone collagen propeptide ammonia sugar pills

A collagen peptide glucosamine tablet, a technology for increasing bone density, which can be used in medical preparations with non-active ingredients, medical preparations containing active ingredients, bone diseases, etc. The effect of convenience, scientific and reasonable formula, and easy-to-obtain raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

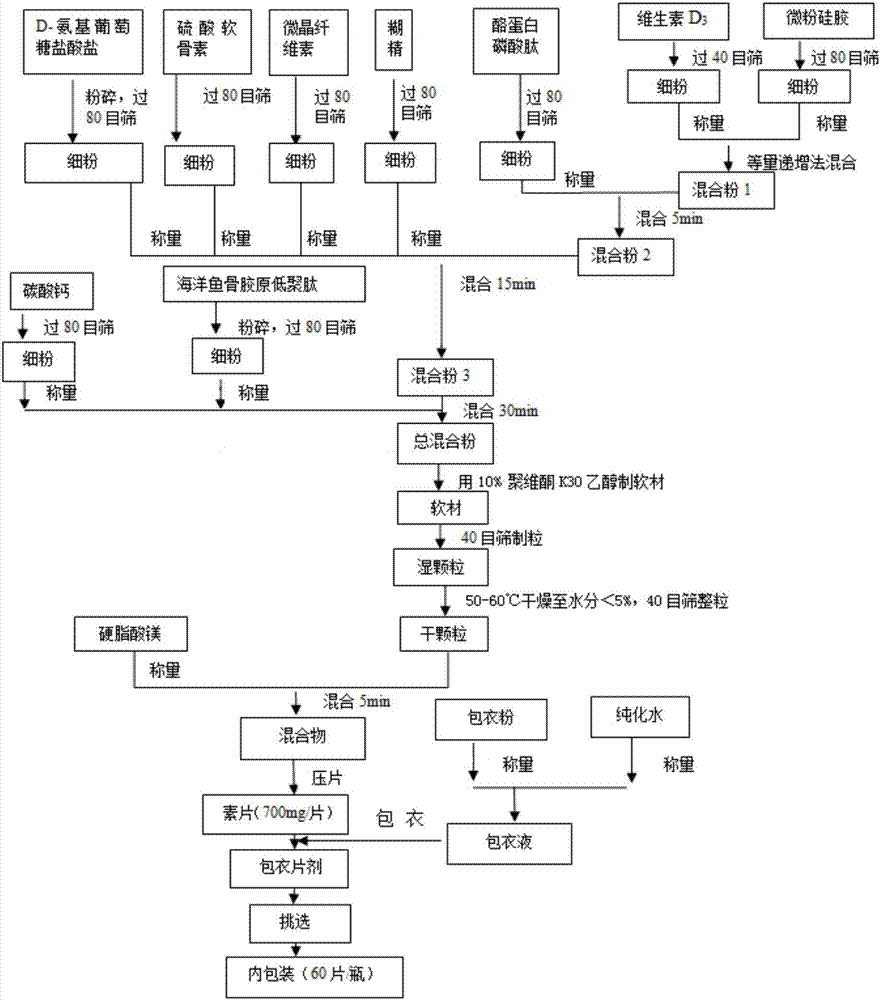

Method used

Image

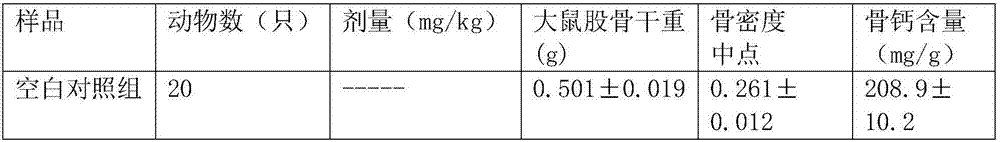

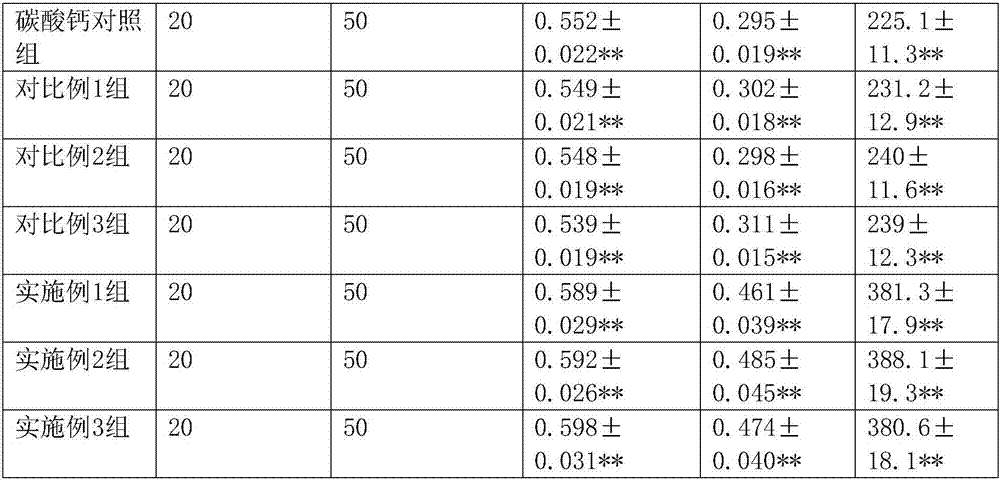

Examples

Embodiment 1

[0027] (1) After pulverizing 150 parts of marine fish bone collagen oligopeptide powder and 80 parts of D-glucosamine hydrochloride respectively, pass through a 80-mesh sieve and weigh for later use; mix 200 parts of calcium carbonate, 10 parts of chondroitin sulfate, 10 parts of protein phosphopeptide powder, 70 parts of microcrystalline cellulose, 50 parts of dextrin, and 3 parts of micropowdered silica gel were respectively passed through an 80-mesh sieve, and vitamin D 3 0.10 parts passed through a 40-mesh sieve, weighed for later use; weighed 1 part of magnesium stearate, 10 parts of povidone K30, and 10 parts of coating powder for later use;

[0028] (2) Take the above-mentioned vitamin D 3 Mix the fine powder with the same amount of micro-powder silica gel fine powder, and then take the same amount of micro-powder silica gel fine powder as the mixed powder and mix evenly, and increase the amount in this way until they are all mixed evenly and have the same color, and m...

Embodiment 2

[0036] (1) After pulverizing 172.5 parts of marine fish bone collagen oligopeptide powder and 90 parts of D-glucosamine hydrochloride, pass through an 80-mesh sieve, and weigh them for later use; mix 210 parts of calcium carbonate, 30 parts of chondroitin sulfate, 15 parts of protein phosphopeptide powder, 80.5 parts of microcrystalline cellulose, 75.05 parts of dextrin, and 6 parts of micropowdered silica gel were respectively passed through an 80-mesh sieve, and 0.45 parts of vitamin D3 were passed through a 40-mesh sieve, and weighed for later use; 17.5 parts, 17.5 parts of povidone K30, 21 parts of coating powder for subsequent use;

[0037] (2) Mix the above-mentioned fine powder of vitamin D3 with the same amount of micronized silica gel fine powder, and then take the same amount of micronized silica gel fine powder as the mixed powder and mix evenly, so that the amount is increased until all are mixed evenly and the color is consistent. Mixed powder 1 was obtained; case...

Embodiment 3

[0045] (1) After pulverizing 200 parts of marine fish bone collagen oligopeptide powder and 100 parts of D-glucosamine hydrochloride respectively, pass through an 80-mesh sieve and weigh them for later use; mix 250 parts of calcium carbonate, 50 parts of chondroitin sulfate, 20 parts of protein phosphopeptide powder, 100 parts of microcrystalline cellulose, 80 parts of dextrin, and 9 parts of micropowdered silica gel were respectively passed through an 80-mesh sieve, and vitamin D 3 0.5 parts passed through a 40-mesh sieve, weighed for later use; 5 parts of magnesium stearate, 20 parts of povidone K30, and 25 parts of coating powder were weighed for later use;

[0046] (2) The above-mentioned vitamin D 3 Mix the fine powder with the same amount of micro-powder silica gel fine powder, and then take the same amount of micro-powder silica gel fine powder as the mixed powder and mix evenly, and increase the amount in this way until they are all mixed evenly and have the same colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com