Co-production medium, preparation method and application thereof

A co-production culture medium and culture medium technology, applied in the direction of culture medium, botany equipment and methods, applications, etc., to achieve the effects of reasonable collocation, low production cost, improved space utilization and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

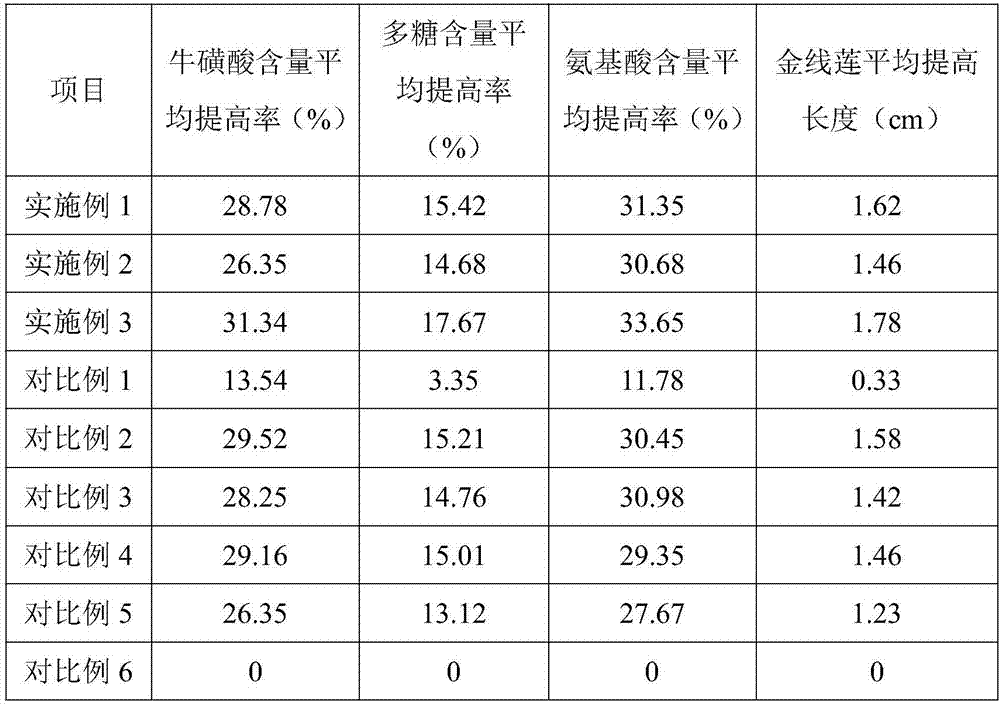

Examples

Embodiment 1

[0059] A new process for the production of shiitake mushrooms and golden clematis, comprising the following steps:

[0060] S1: Cultivation of shiitake mushroom hyphae: prepare shiitake mushroom culture medium, which includes the following raw materials in parts by weight: 102 parts of rice straw debris, 30 parts of citrus juice, 20 parts of peanut cake, and 6 parts of potassium chloride , 5 parts of sodium nitrate, 5 parts of ammonium sulfate, 0.35 parts of sodium iodate, 0.7 parts of calcium nitrate, 0.9 parts of magnesium sulfate, 0.4 parts of zinc nitrate, 0.35 parts of manganese chloride, 0.5 parts of sodium borate, 0.4 parts of sodium molybdate, nitric acid 0.2 part of iron, 0.3 part of copper chloride and water, the amount of added water makes the water content of the culture medium be 68%, and the pH value of the culture medium is 5.6. Sterilize at 160KPa for 4 minutes, insert the mother seed of shiitake mushroom mycelium, cultivate at 25°C to form the shiitake mushroo...

Embodiment 2

[0067] A new process for the production of shiitake mushrooms and golden clematis, comprising the following steps:

[0068] S1: Cultivation of shiitake mushroom hyphae: prepare shiitake mushroom culture medium, which includes the following raw materials in parts by weight: 93 parts of rice straw debris, 22 parts of citrus juice, 15 parts of peanut cake, and 4 parts of potassium chloride , 3 parts of sodium nitrate, 3.5 parts of ammonium sulfate, 0.3 parts of sodium iodate, 0.6 parts of calcium nitrate, 0.8 parts of magnesium sulfate, 0.3 parts of zinc nitrate, 0.3 parts of manganese chloride, 0.4 parts of sodium borate, 0.3 parts of sodium molybdate, nitric acid 0.2 part of iron, 0.2 part of copper chloride and water, the amount of added water makes the water content of the culture medium be 65%, and the pH value of the culture medium is 5.2. Sterilize for 5 minutes at 150KPa, insert the mother seed of shiitake mushroom mycelium, cultivate at 23°C to form the shiitake mushroom...

Embodiment 3

[0075] A new process for the production of shiitake mushrooms and golden clematis, comprising the following steps:

[0076]S1: Cultivation of shiitake mushroom hyphae: prepare shiitake mushroom culture medium, which includes the following raw materials in parts by weight: 105 parts of rice straw debris, 40 parts of citrus juice, 22 parts of peanut cake, and 7 parts of potassium chloride , 6 parts of sodium nitrate, 6 parts of ammonium sulfate, 0.4 parts of sodium iodate, 0.8 parts of calcium nitrate, 1 part of magnesium sulfate, 0.5 parts of zinc nitrate, 0.4 parts of manganese chloride, 0.6 parts of sodium borate, 0.5 parts of sodium molybdate, nitric acid 0.3 part of iron, 0.4 part of copper chloride and water, the amount of added water makes the water content of the culture medium be 70%, and the pH value of the culture medium is 6. Sterilize for 3 minutes at 170KPa, insert the mother seed of shiitake mushroom mycelium, cultivate at 26°C to form the shiitake mushroom myceli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com