Full-aluminum backfield crystalline silicon solar cell back sliver paste, preparation method thereof and use thereof

A solar cell, all-aluminum back field technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the photoelectric conversion efficiency of the battery, reducing the minority carrier collection rate, reducing the open circuit voltage, etc., to improve the photoelectric conversion. Efficiency Eff, excellent dispersion, the effect of improving open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

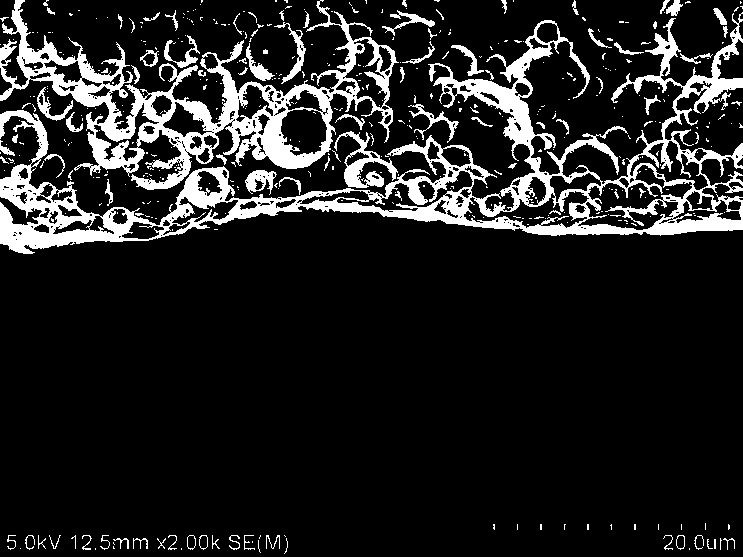

Image

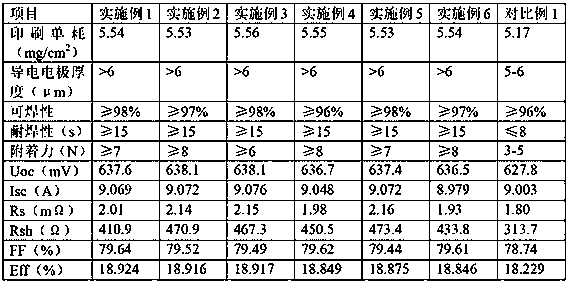

Examples

Embodiment 1

[0047] A silver paste on the back of an all-aluminum back field crystalline silicon solar cell, the paste consists of the following components:

[0048] 12g spherical silver powder;

[0049] Flake silver powder 60g;

[0050] Glass powder 6g;

[0052] Organic carrier 20g;

[0053] Wetting agent Tego Wet KL 245 0.1g;

[0054] Dispersant SN-5040 0.1g;

[0055] Leveling agent BYK-331 0.1g;

[0056] Dipoly rhodium acetate 0.05g.

[0057] Wherein, the average particle size of the spherical silver powder is 0.9 μm, D 50 0.9μm, tap density 6.5g / m 3 , The ablation rate is 0.3-0.8%.

[0058] Flake silver powder average particle size 2.5-5.0μm, D 50 3.1μm, tap density 4.0-6.0g / m 3 .

[0059]The glass powder is lead-free glass with a softening point of 700-750 o C, the average particle size is 3.5 μm.

[0060] Wetting agent, dispersant, leveling agent and adhesion promoter are used as processing aids as a whole, and the overall dosage is 0.2-0....

Embodiment 2

[0079] 1) Preparation of organic carrier: first weigh 20g of liquid solvent terpineol, 20g of butyl carbitol, 20g of butyl carbitol acetate, 20g of acetyl tributyl citrate, and 5g of dioctyl phthalate In a 250ml beaker, weigh 5g of polymer solid powder ethylcellulose, 4g of cellulose acetate butyrate, 2g of acrylic resin, and 4g of polyimide resin, and place the solid powder in a liquid mixed solvent at a temperature of 85 o Heat and stir in the constant temperature water tank of C until the resin is completely dissolved, then filter with a 300-mesh sieve to obtain an organic carrier, store it at a lower temperature, and keep it for later use;

[0080] 2) Preparation of slurry: weigh D 50 1.6μm, tap density 4.5g / m 3 20g of spherical silver powder, D 50 3.8μm, tap density 4.0g / m 3 40g of flaky silver powder with a softening point of 750 o C's lead-free glass powder 5.8g, calcium acetate 4g, organic vehicle 30g prepared above, wetting agent Tego Wet KL 245 0.05g, dispersant...

Embodiment 3

[0083] 1) Preparation of organic carrier: First weigh 15g of liquid solvent terpineol, 25g of butyl carbitol, 25g of butyl carbitol acetate, 15g of acetyl tributyl citrate, and 8g of dioctyl phthalate In a 250ml beaker, weigh 3g of polymer solid powder ethyl cellulose, 3g of cellulose acetate butyrate, 2g of acrylic resin, and 4g of polyimide resin, and place the solid powder in a liquid mixed solvent at a temperature of 80 o Heat and stir in the constant temperature water tank of C until the resin is completely dissolved, then filter with a 300-mesh sieve to obtain an organic carrier, store it at a lower temperature, and keep it for later use;

[0084] 2) Preparation of slurry: weigh D 50 1.2μm, tap density 5.3g / m 3 15.4g of spherical silver powder, D 50 3.5μm, tap density 4.8g / m 3 The flaky silver powder 55.1g, the softening point is 720 o 4g of lead-free glass powder of C, 3g of calcium oxalate, 22g of the organic vehicle prepared above, 0.1g of wetting agent Tego Wet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com