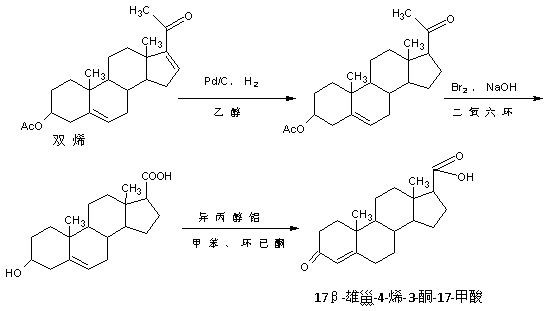

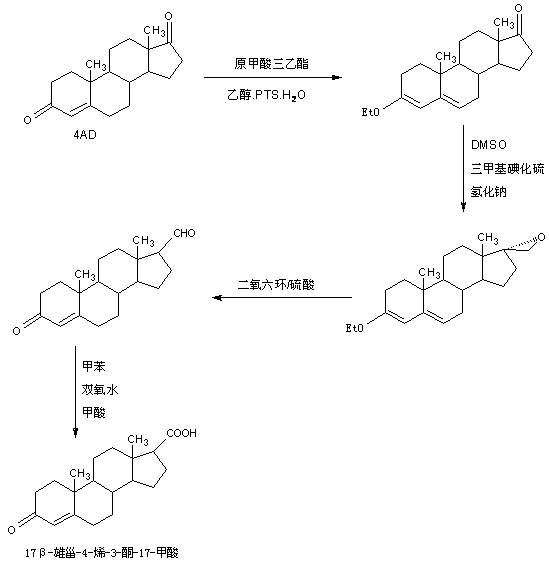

Preparation method of 17 beta-androst-4-ene-3-one-17-carboxylic acid

A technology of androstenedione and androstene, which is applied in the field of preparation of steroid hormone drug intermediates, can solve the problems of complicated process operation, difficult environmental protection treatment, expensive synthetic raw materials, etc., and achieves cheap and easy-to-obtain raw materials and good product quality , the effect of short synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A. Preparation of ether compounds

[0031] In a 1000ml three-neck flask, add 100g 4AD, 200ml ethanol, 80ml triethyl orthoformate, 2g p-toluenesulfonic acid, keep warm at 20-25°C and stir for 12-16 hours. TLC detects the end point of the reaction. After the reaction, add 3ml of pyridine, stirred for 20-25 minutes to neutralize the acid, then cooled the system to -5-0°C, stirred and crystallized for 2-3 hours, filtered with suction, washed with a small amount of ethanol, combined the washing liquid and the filtrate, recovered the solvent and used the crude product; filtered The cake was dried below 70°C to obtain 101.6 g of etherified compound, the HPLC content was 99.2%, and the weight yield was 101.6%.

[0032] B. Preparation of epoxy

[0033]In a 2000ml three-necked flask, add 100g of the above ether compound, 600ml DMSO, and 60g trimethylsulfur iodide, stir to dissolve it completely, then slowly add 10g of 80% sodium hydride at 20-25°C, after the addition, Continue ...

Embodiment 2

[0039] A. Preparation of ether compounds

[0040] In a 1000ml three-neck flask, add 100g 4AD, 600ml dichloromethane, 80ml triethyl orthoformate, 2g p-toluenesulfonic acid, keep warm at 20-25°C and stir for 12-16 hours. TLC detects the end point of the reaction. , add 3ml of pyridine, stir for 20-25 minutes to neutralize the acid, concentrate under reduced pressure, recover dichloromethane, cool down, add 100ml of ethanol, then cool the system to -5-0°C, stir and crystallize for 2-3 hours, and filter with suction. A small amount of ethanol was washed, the washing liquid and the filtrate were combined, the solvent was recovered and the crude product was reused; the filter cake was dried below 70°C to obtain 100.2 g of ether compound, the HPLC content was 99.4%, and the weight yield was 100.2%.

[0041] B. Preparation of epoxy

[0042] In a 2000ml three-necked flask, add 100g of the above-mentioned self-made ether compound, 600ml of DME, and 60g of trimethylsulfur iodide, stir t...

Embodiment 3

[0048] A. Preparation of ether compounds

[0049] In a 1000ml three-neck flask, add 100g 4AD, 200ml ethanol, and 80ml triethyl orthoformate, inject 2g of HCl gas, seal it, keep it warm at 2025°C and stir for 12-16 hours. TLC detects the end point of the reaction. After the reaction, add 3ml of pyridine, stirred for 20-25 minutes to neutralize the acid, then cooled the system to -5-0°C, stirred and crystallized for 2-3 hours, filtered with suction, washed with a small amount of ethanol, combined the lotion and filtrate, recovered the solvent and used the crude product; filtered The cake was dried below 70°C to obtain 103.2g of etherified compound,

[0050] HPLC content 99.1%, weight yield 103.2%.

[0051] B. Preparation of epoxy

[0052] In a 2000ml three-necked flask, add 100g of the above ether compound, 600mlTHF, 60g trimethylsulfur iodide, stir to dissolve completely, then slowly add 10g of 80% methyllithium at 20-25°C, after the addition, Continue to heat and stir the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com