Stable marble glue

A kind of marble glue, stable technology, applied in the direction of adhesive, adhesive type, graft polymer adhesive, etc., can solve the problems of unsatisfactory effect, mechanical properties attenuation, pollution, etc., to solve the problem of internal gel Problems, colloidal gel prevention, polymerization inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

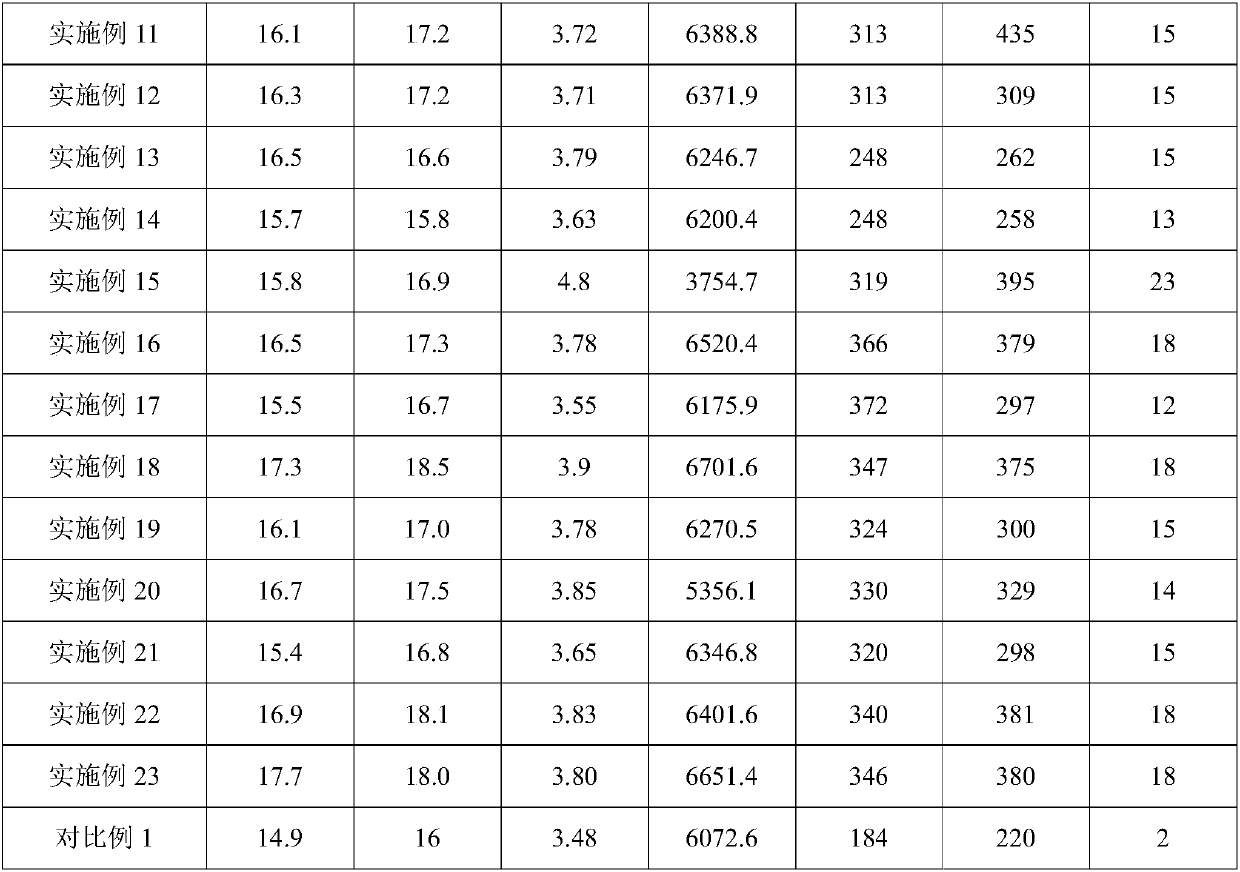

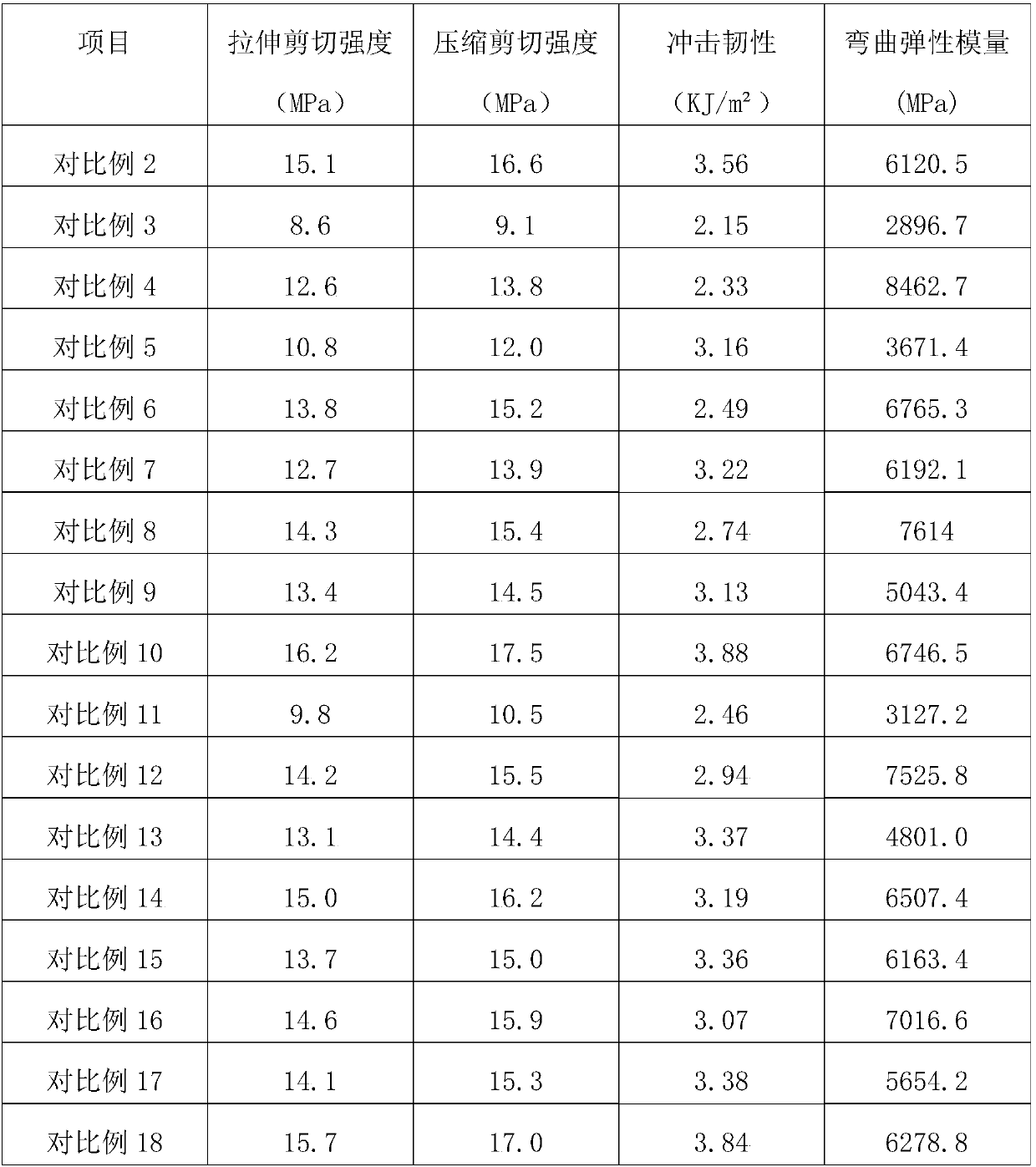

Examples

Embodiment 1

[0041] Stable marble glue is calculated in parts by weight, consisting of 100 parts of phthalic acid and isophthalic acid type unsaturated polyester resin (including 8 parts of styrene, 6 parts of divinylbenzene, α-methylstyrene 4.5 parts, 1.5 parts of isobornyl acrylate, 0.024 parts of 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide, 0.04 parts of benzoquinone, 0.016 parts of hydroquinone, N, N -Dimethylaniline 0.8 parts), hydrogenated castor oil 2 parts, attapulgite 2 parts, montmorillonite 2 parts, sepiolite fiber 2 parts, silicon dioxide 50 parts, ground calcium carbonate 50 parts, activated calcium carbonate 50 servings make up.

Embodiment 2

[0043] Stable marble glue consists of 100 parts of phthalic acid and isophthalic acid type unsaturated polyester resin (including 10 parts of styrene, 4 parts of divinylbenzene, α-methylstyrene, etc.) in parts by weight. 3 parts, 3 parts of isobornyl acrylate, 0.030 parts of 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide, 0.015 parts of benzoquinone, 0.015 parts of hydroquinone, N,N -Dimethylaniline 0.6 parts), hydrogenated castor oil 2 parts, attapulgite 2 parts, montmorillonite 2 parts, sepiolite fiber 2 parts, silicon dioxide 50 parts, ground calcium carbonate 50 parts, activated calcium carbonate 50 servings make up.

Embodiment 3

[0045] Stable marble glue consists of 100 parts of phthalic acid and isophthalic acid type unsaturated polyester resin (including 12 parts of styrene, 12.6 parts of divinylbenzene, α-methylstyrene, etc.) in parts by weight. 2.7 parts, 2.7 parts of isobornyl acrylate, 0.025 parts of 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide, 0.0125 parts of benzoquinone, 0.0125 parts of hydroquinone, N,N -Dimethylaniline 0.5 parts), hydrogenated castor oil 3 parts, attapulgite 6 parts, montmorillonite 2 parts, sepiolite fiber 2 parts, silicon dioxide 50 parts, ground calcium carbonate 50 parts, activated calcium carbonate 50 servings make up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com