Feed capable of improving production performance of broiler chickens

A production performance and feed technology, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve the problems of unsatisfactory amino acid actual effect, shortage of protein feed, low animal feed intake, etc., to improve biological The effect of utilization value, economical utilization of feed protein, and efficient utilization of protein source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific preparation method of earthworm fermentation product:

[0024] Earthworms are used as raw materials to be frozen into powder with liquid nitrogen and then added to water for grinding to obtain earthworm pulp, then inoculated with Lactobacillus casei and Lactobacillus acidophilus for fermentation at 22°C for 24 hours, and then inoculated with Bifidobacterium in Ferment at a temperature of 24°C for 24 hours, then stop the fermentation, filter the fermented liquid to obtain the filtrate, then concentrate and dry. The total added amount of Lactobacillus casei and Lactobacillus acidophilus is 0.1% of the weight of the earthworm powder, and the added amount of the bifidobacterium is 0.3% of the weight of the earthworm powder.

Embodiment 2

[0026] The specific preparation method of earthworm fermentation product:

[0027] Earthworms are used as raw materials to be frozen into powder with liquid nitrogen and then added to water for grinding to obtain earthworm pulp, then inoculated with Lactobacillus casei and Lactobacillus acidophilus for fermentation at 27°C for 12 hours, and then inoculated with Bifidobacterium in Ferment at a temperature of 20°C for 36 hours, then stop the fermentation, filter the fermented liquid to obtain the filtrate, and then concentrate and dry. The total added amount of Lactobacillus casei and Lactobacillus acidophilus is 0.3% of the weight of the earthworm powder, and the added amount of the bifidobacterium is 0.1% of the weight of the earthworm powder.

Embodiment 3

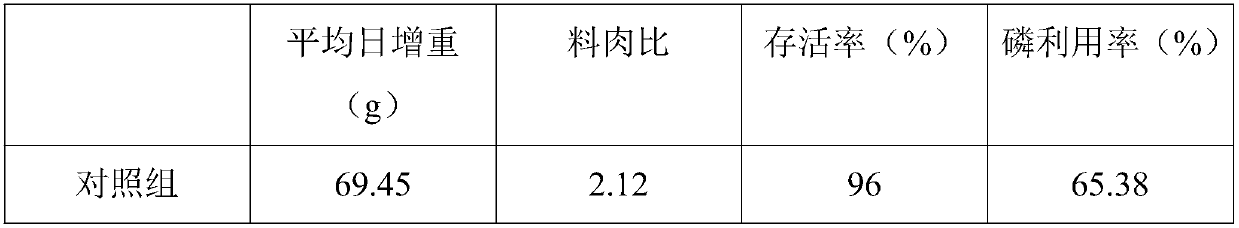

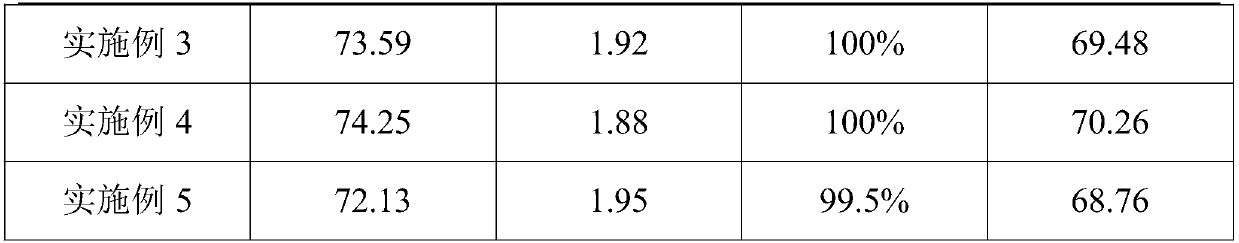

[0029] A feed for improving the production performance of broilers, calculated by weight percentage, is made of the following raw materials:

[0030] 500 parts of corn, 100 parts of soybean meal, 80 parts of rapeseed meal, 90 parts of earthworm fermentation product of Example 1, 20 parts of beer tank, 70 parts of peanut meal, 1 part of compound amino acid, 2 parts of compound enzyme, 1 part of trace element, plant 1 part of acid enzyme and 10 parts of calcium hydrogen phosphate.

[0031] The compound amino acid is a mixture of methionine, phenylalanine and lysine.

[0032] The compound enzyme is composed of cellulase, β-glucanase, xylanase, α-amylase and carrier shell powder.

[0033] Trace elements are composed of ferrous sulfate, zinc sulfate, copper sulfate, manganese sulfate, calcium iodate and stone powder as a carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com