Controlled-releasing herbicide containing cyhalofop butyl, mefenacet and pyrazosulfuron ethyl

A technology of fenflunom and pyrazosulfuron is applied in the directions of herbicides, algaecides, biocides, biocides, etc., and can solve the problem that the broad-leaved and sedge weeds and rice field barnyard cannot be completely controlled. It can reduce the labor intensity, improve the herbicidal effect, and improve the safety of rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

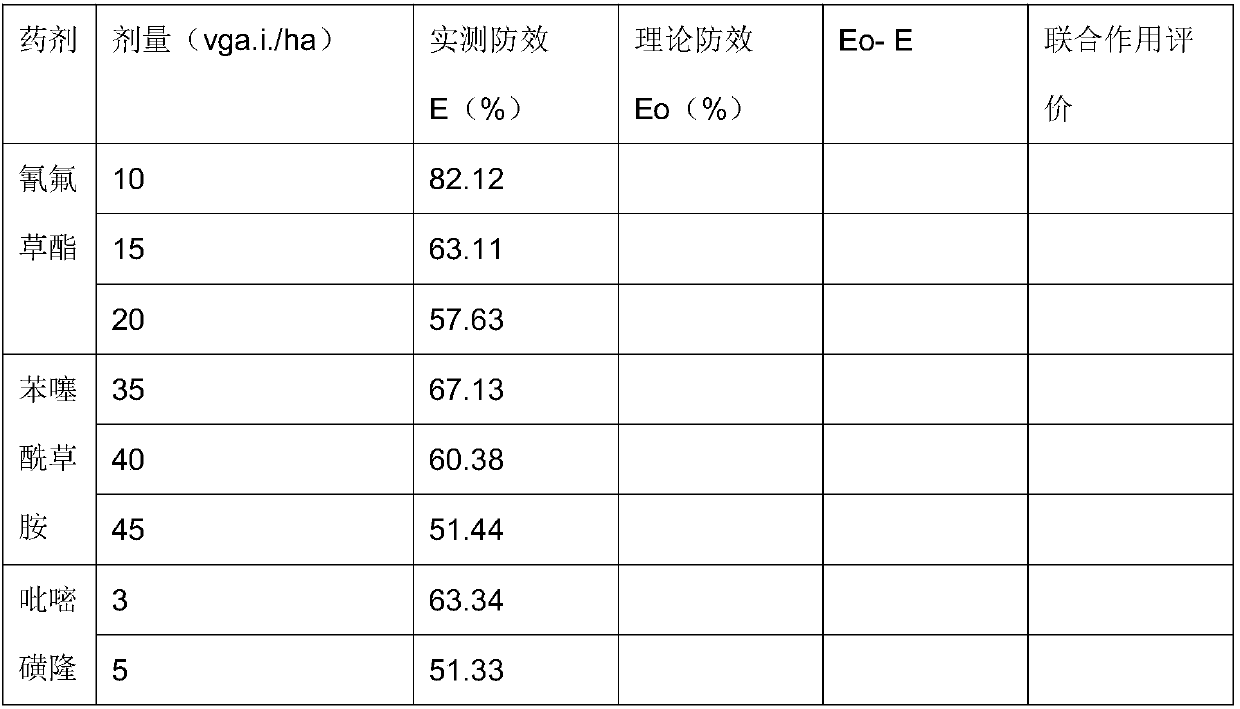

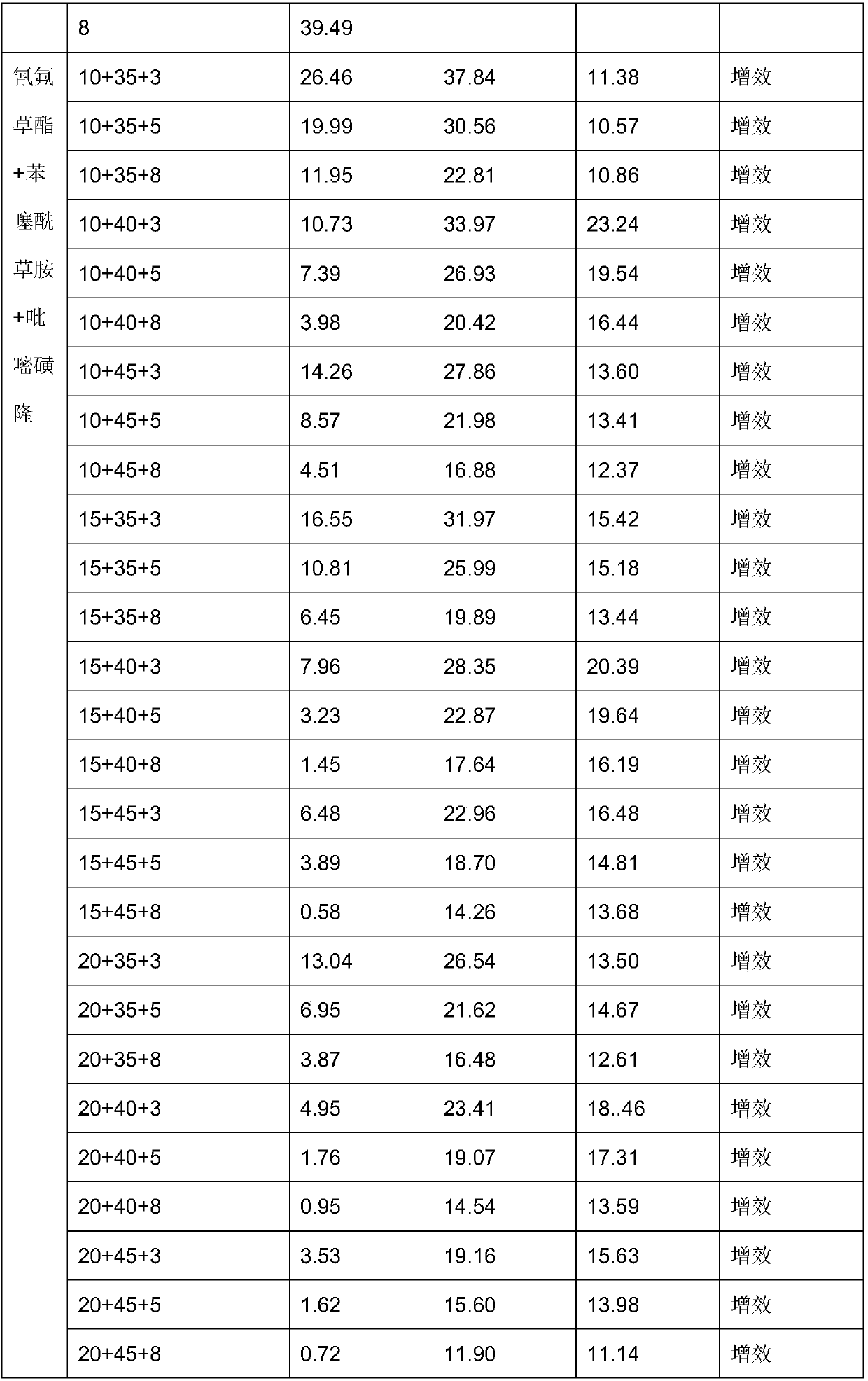

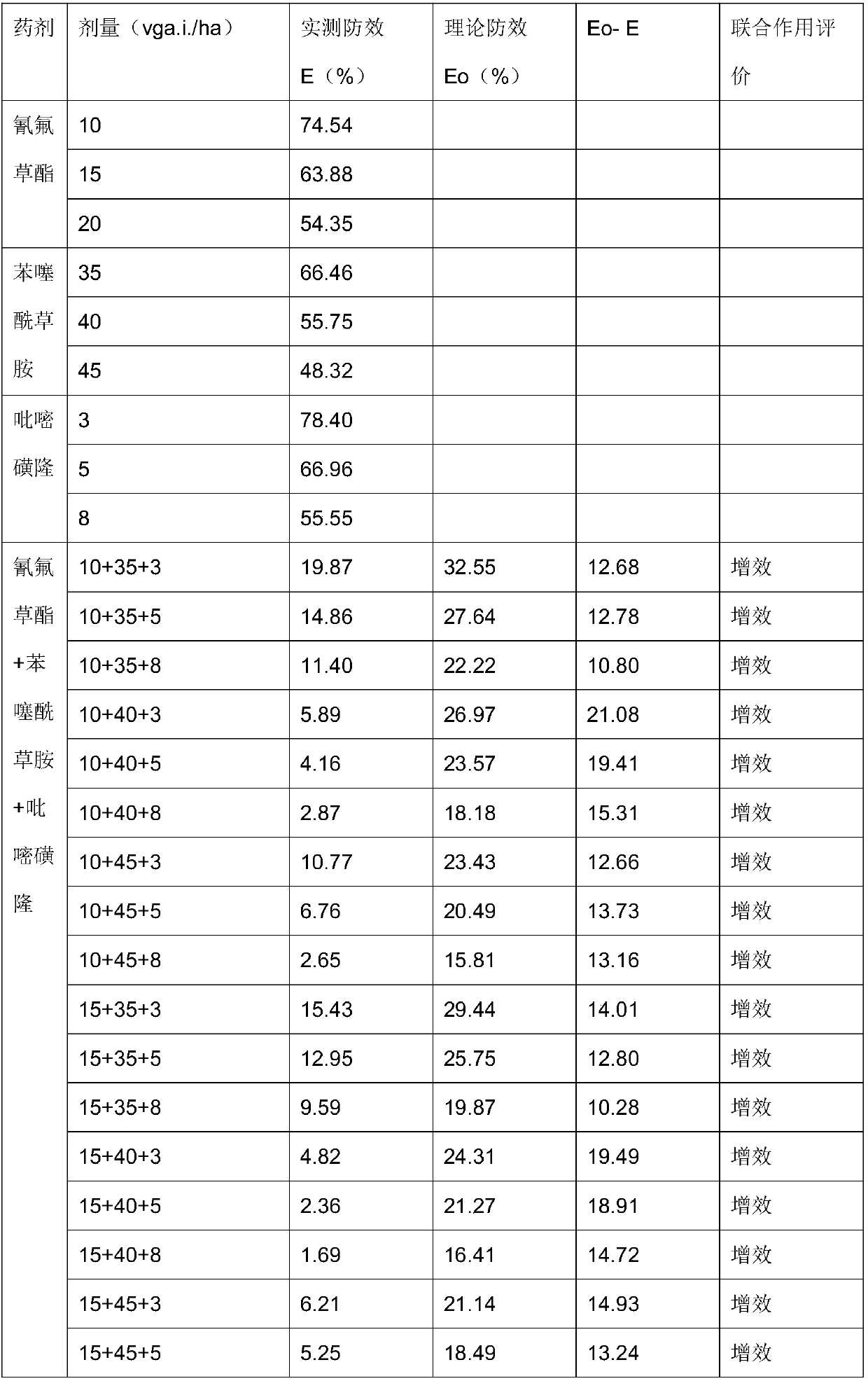

Examples

Embodiment 1

[0027] Example 1: 48% Cyhalofop-methyl-Pyrazosulfuron-Methiazide Sustained Release Agent

[0028]Cyhalofop-methyl 10%, pyrazosulfuron-methyl 3%, mefenacet 35%, citric acid 5%, sodium carbonate 6%, sodium lignosulfonate 5%, sodium dodecylbenzenesulfonate 1% , corn starch 1%, magnesium aluminum silicate 1.5%, kaolin added to 16%, slow-release microparticle system 19% Weigh each component according to the above formula, and mix cyhalofop-ethyl, pyrazosulfuron-methyl, mefenamide , dispersant (sodium lignosulfonate), wetting agent (sodium dodecylbenzenesulfonate), citric acid, sodium carbonate, corn starch, magnesium aluminum silicate, kaolin, and slow-release particulate system are added to the conical mixing Mix evenly in the machine, add the evenly mixed material to the jet mill for crushing, and then mix evenly. Add an appropriate amount of binder aqueous solution to mix and granulate, and after granulation, enter the tablet machine for tableting. Obtained 60% cyhalofop-methy...

Embodiment 2

[0031] Example 2 50% Cyhalofop-methyl-Pyrazosulfuron-Methiazide Sustained Release Agent

[0032] Cyhalofop-methyl 10%, pyrazosulfuron-methyl 5%, mefenacet 35%, sodium lignosulfonate 7%, dispersant NNO5%, sodium dodecylbenzenesulfonate 1%, tartaric acid 5%, 6% of ammonium bicarbonate, 2% of polycellulose sodium, 2% of white carbon black, 100% of pottery clay, 19% of sustained-release microparticle system. - Benzofen sustained-release agent;

[0033] The preparation method of the microparticle system is as follows: weigh 9 starches, dissolve them with 4 parts of 1% acetic acid solution, add 3 parts of calcium chloride at 800 rpm / min, stir and dissolve evenly, and obtain starch-calcium chloride solution for later use In addition, take 6 parts of gum arabic and dissolve it with 2 parts of deionized water to obtain a gum arabic solution; then weigh 3 parts of a-pinene, emulsify with 4 parts of Tween 80, and emulsify for 20 minutes, and add the emulsion to the starch - Stir evenly...

Embodiment 3

[0035] Example 3 53% cyhalofop-methyl-pyrazosulfuron-fenthiazide sustained release agent

[0036] Cyhalofop-methyl 10%, pyrazosulfuron-methyl 8%, mefenacet 38%, nonylphenol polyoxyethylene ether 2%, dispersant NNO 5%, sodium dodecylbenzenesulfonate 0.5%, 5% lemon, 6% ammonium bicarbonate, 2% polycellulose sodium, 2% magnesium aluminum silicate, 100% pottery clay, 15% slow-release microparticle system -Pyrazosulfuron-methyl-Methiazide Sustained-release Agent;

[0037] The preparation method of the microparticle system is as follows: Weigh 6 starches, dissolve them with 3 parts of 1% acetic acid solution, add 2 parts of calcium chloride at 800 rpm / min, stir and dissolve evenly, and obtain starch-calcium chloride solution for later use Another 6 parts of gum arabic was weighed and dissolved in 4 minutes of deionized water to obtain a gum arabic solution; then 3 parts of a-pinene was weighed and emulsified with 1.5 parts of Tween 80 for 10 minutes of emulsification time, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com