GaP nanowires as well as preparation method and application thereof

A technology of nanowires and conductive substrates, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complexity, difficulty in obtaining, high price of single crystal GaP and InP substrates, and achieve uniform size and good crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

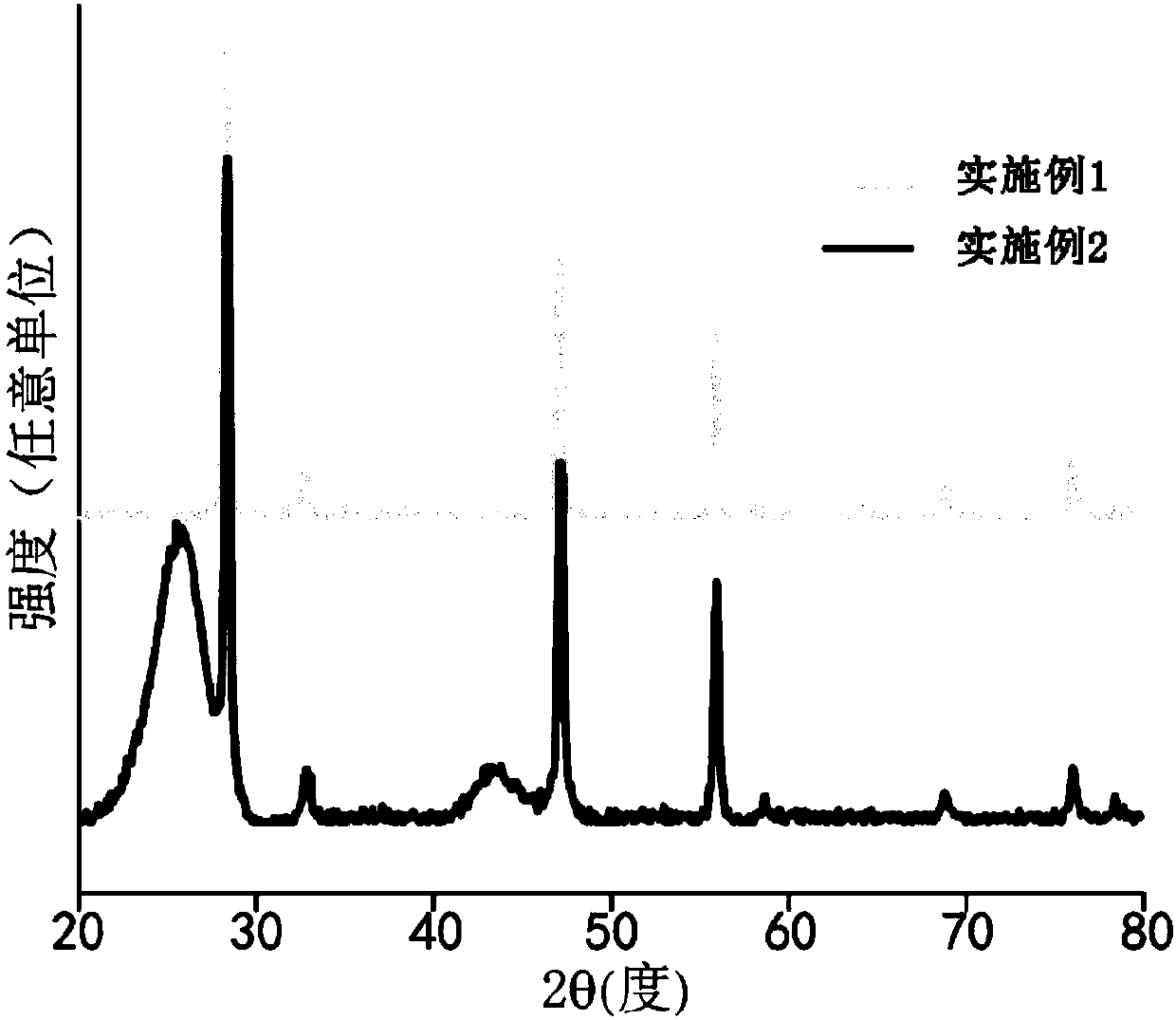

Embodiment 1

[0094] This embodiment provides a preparation method of GaP nanowires, the specific method is:

[0095] (1) Weigh about 15mg of GaP powder and put it into a quartz boat. Then the quartz boat 1 containing the GaP powder was loaded into a quartz tube with both ends opened.

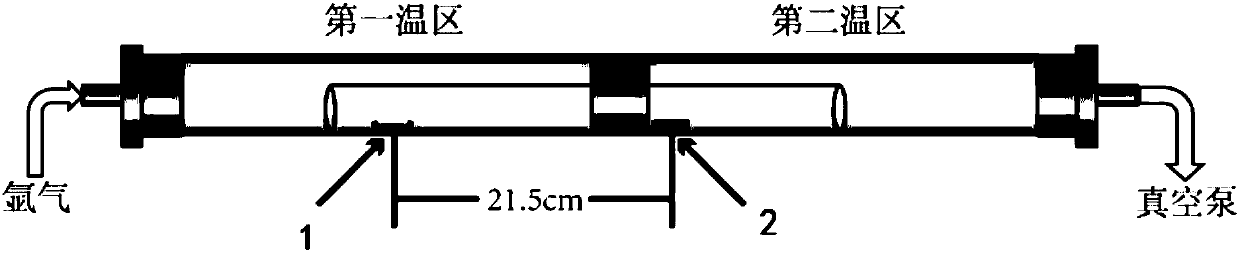

[0096] (2) Cut the single-sided polished single-crystal silicon (p-type) wafer, which is the conductive substrate to grow GaP nanowires, into 1cm×1cm size, and ultrasonically clean it in acetone, isopropanol, and water for 15 minutes respectively. After the cleaned silicon substrate is blown dry with nitrogen flow, the silicon substrate 2 covered with gold film is obtained, which is placed in the chamber of the ion sputtering instrument with the polished side facing up, and the gold film is sprayed, and then it is polished from the other side of the quartz tube Put it face up into the quartz tube so that the distance from the quartz boat is 21.5 cm. Put the quartz tube into a tube furnace with two temperat...

Embodiment 2

[0104] This embodiment provides a preparation method of GaP nanowires, the specific method is:

[0105] (1) Weigh about 20mg of GaP powder and put it into a quartz boat. The quartz boat is then loaded into a quartz tube that is open at both ends.

[0106] (2) The carbon cloth, the conductive substrate to be grown GaP nanowires, was cut into 1cm×1cm size, cleaned in acetone by ultrasonic for 5 minutes×3 times, followed by ultrasonic cleaning in isopropanol and water for 15 minutes respectively. After the cleaned carbon cloth substrate was blown dry with a nitrogen flow, it was fixed on a clean glass sheet, and then placed in the chamber of the ion sputtering instrument to spray-coat gold film (spray-coating twice, one on each side of the front and back). Then fix the carbon cloth base after sputtering the gold film on the quartz plate (size 1.5cm×8cm), and then put the quartz plate into the quartz tube from the other side of the quartz tube, so that the distance between the ca...

Embodiment 3

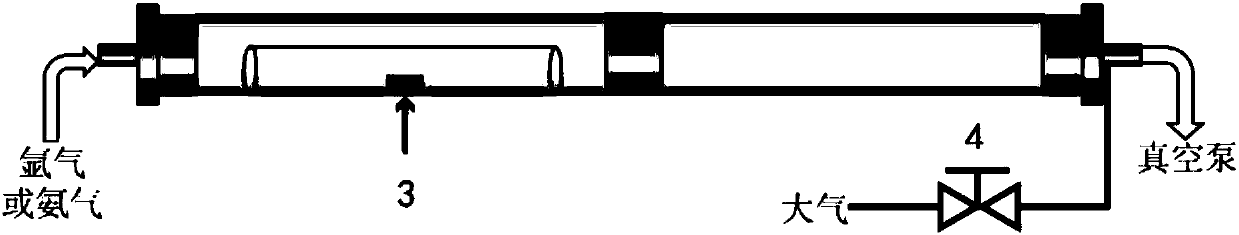

[0113] This embodiment provides a method for preparing GaP / GaPN core-shell nanowires, the specific method is:

[0114] (1) Take an appropriate amount of homemade acidified KI / I 2 The solution is packed in a beaker, and the GaP nanowire sample grown on a silicon substrate prepared according to the method of Example 1 is immersed in the solution, taken out after 4 minutes, and the sample is cleaned immediately with deionized water, and then the sample is washed with nitrogen flow. Blow dry to obtain the pretreated GaP nanowire sample 3. Acidified KI / I 2 KI, I in solution 2 The mass ratio with water is 4:1:40, concentrated hydrochloric acid and by KI, I 2The volume ratio of the solution formed with water is 1:9.

[0115] (2) Put the pretreated GaP nanowire sample 3 into a quartz tube, and put the quartz tube into a tube furnace with two temperature zones, so that the sample is located in the center of the first temperature zone. The specific placement positions of the quartz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Limiting current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com