Biomass granular activated carbon and preparation method thereof

A technology of biomass particles and activated carbon, which is applied in the field of biomass waste recycling, can solve the problems of reduced content of active ingredients, small number of pores, and few micropores, and achieve the effects of increasing pore volume, increasing specific surface area, and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

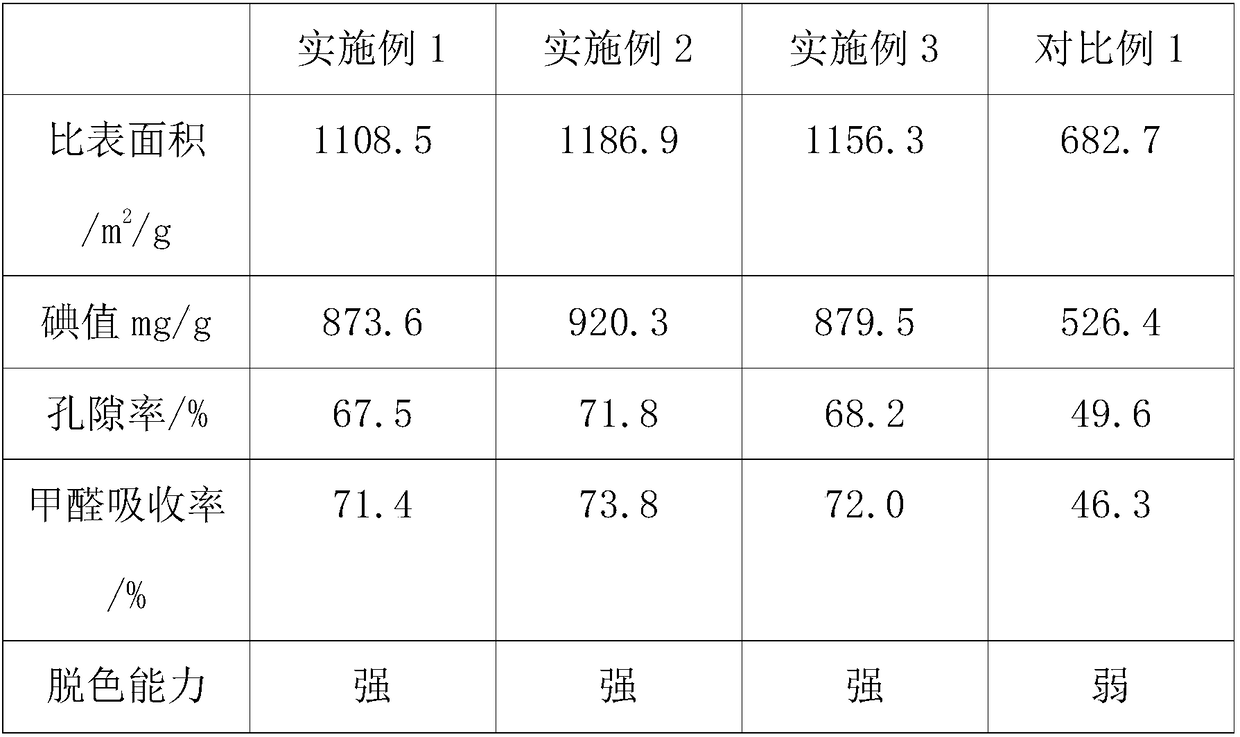

Examples

Embodiment 1

[0025] Step 1: crush 40 parts of coconut shells, 25 parts of miscellaneous wood chips, 16 parts of bagasse, 17 parts of corn stalks, and 18 parts of cow dung to 60 mesh, add 7wt% fermentation bacteria, and cover the film and seal it for 4 days at 25°C to obtain bubbling fermentation products;

[0026] The miscellaneous wood chips include the following components in weight percentage: 45% of bamboo chips, 20% of poplar wood chips, and 35% of pine wood chips; 2 High-yielding yeast, lactic acid bacteria, and Bacillus subtilis are mixed, and the mass ratio of each strain is 2:1:1.5;

[0027] Step 2: Mix 38 parts of fly ash, 16 parts of bentonite, 24 parts of diatomaceous earth and the bubbling fermentation product, and add 5 parts of ammonium bicarbonate. After homogenization, under 60KPa nitrogen condition, the temperature is raised at 8°C / min to 300°C, heat preservation and sintering for 4 hours to prepare porous carbon;

[0028] Step 3: immerse the porous carbon in sodium suc...

Embodiment 2

[0031] The operation is the same as in Example 1, the difference is that step 1: 45 parts of walnut shells, 28 parts of miscellaneous wood chips, 20 parts of bagasse, 20 parts of corn stalks, 22 parts of cow dung, and the weight percentages of each component of miscellaneous wood chips are 37.5% and 25%. , 37.5%, the crushing particle size is 80 meshes, the inoculation amount of fermentation bacteria is 10wt%, and the fermentation temperature and days are respectively 29°C and 5d; Step 2: 40 parts of fly ash, 18 parts of bentonite, 26 parts of diatomite, magnesium carbonate (pore forming agent) 8 parts, the pressure is 70KPa, the heating rate is 10°C / min, the maximum temperature is 400°C, and the holding time is 5h; Step 3: the concentration of sodium succinate is 0.6mol / L, and the soaking time is 4.5h. Activation temperature is 700°C, weight loss rate is 27%; step 4: PH is 6.9, compression pressure is 10MPa, granulation density is 1.4g / cm 3 , The particle size is 1.6cm.

Embodiment 3

[0033] The operation is the same as in Example 1, the difference is that step 1: 50 parts of apricot shells, 30 parts of miscellaneous wood chips, 24 parts of bagasse, 23 parts of corn stalks, 26 parts of cow dung, and the weight percentages of each component of miscellaneous wood chips are 30% and 30%. , 40%, the crushing particle size is 100 mesh, the inoculation amount of fermentation bacteria is 13wt%, the fermentation temperature and the number of days are respectively 33°C and 6d; Step 2: 42 parts of fly ash, 20 parts of bentonite, 28 parts of diatomaceous earth, ammonium phosphate (Porogen) 11 parts, the pressure is 80KPa, the heating rate is 12°C / min, the maximum temperature is 500°C, and the holding time is 6h; Step 3: The concentration of sodium succinate is 0.8mol / L, the soaking time is 6h, and activation The temperature is 750°C, the weight loss rate is 30%; Step 4: PH is 7.0, the compression pressure is 12MPa, and the granulation density is 1.5g / cm 3 , The particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com