Dopamine-hyaluronic acid coating material, preparation method and its application in promoting specific adhesion of dental pulp stem cells to dentin

A technology of dental pulp stem cells and hyaluronic acid, which is applied in the directions of hyaluronic acid coating, chitin polysaccharide coating, coating, etc. The odontoblast layer and dentin are poorly formed, and the regeneration effect of the pulp-dentin complex is not good, so as to avoid toxic side effects, good biocompatibility, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

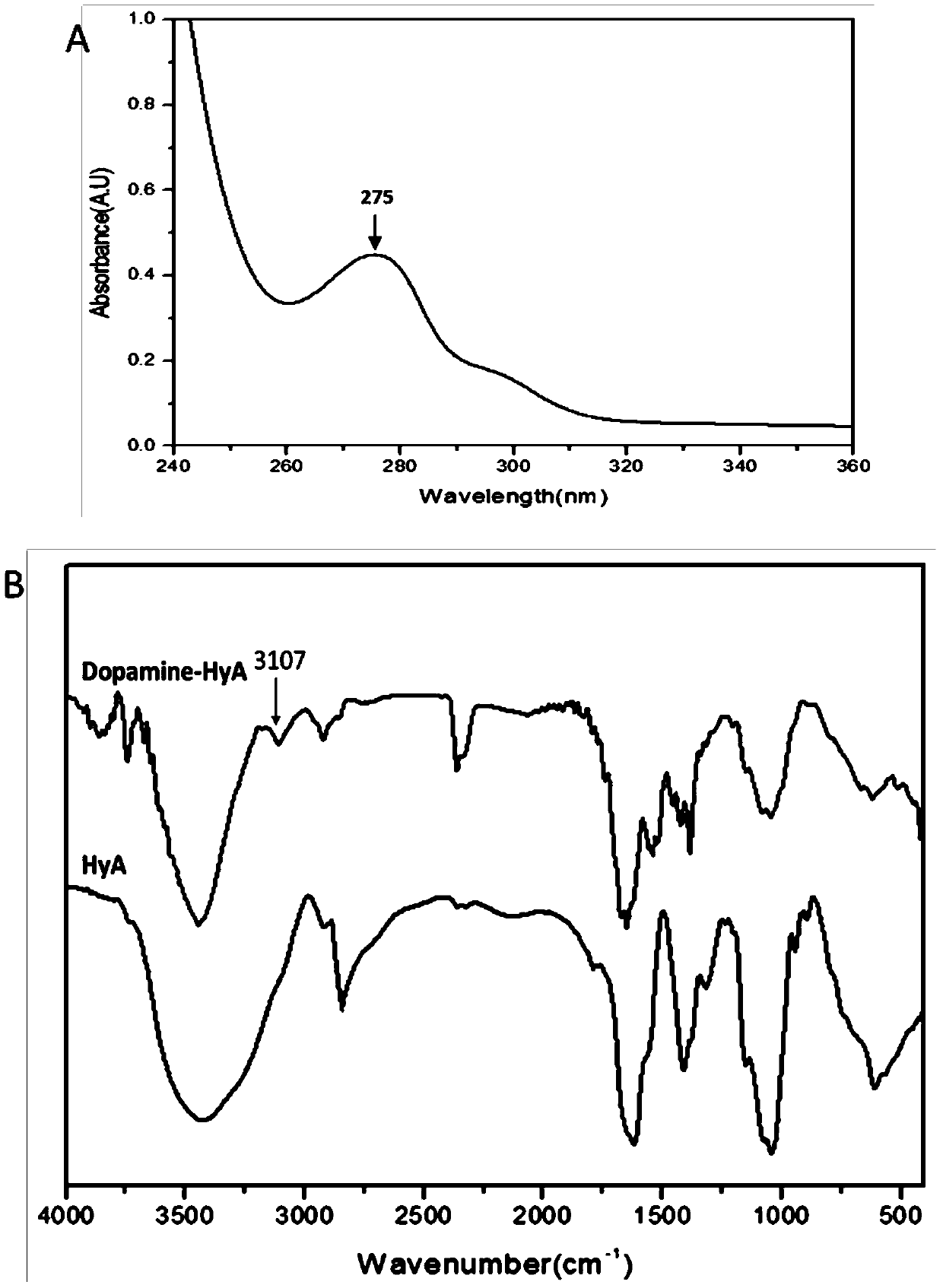

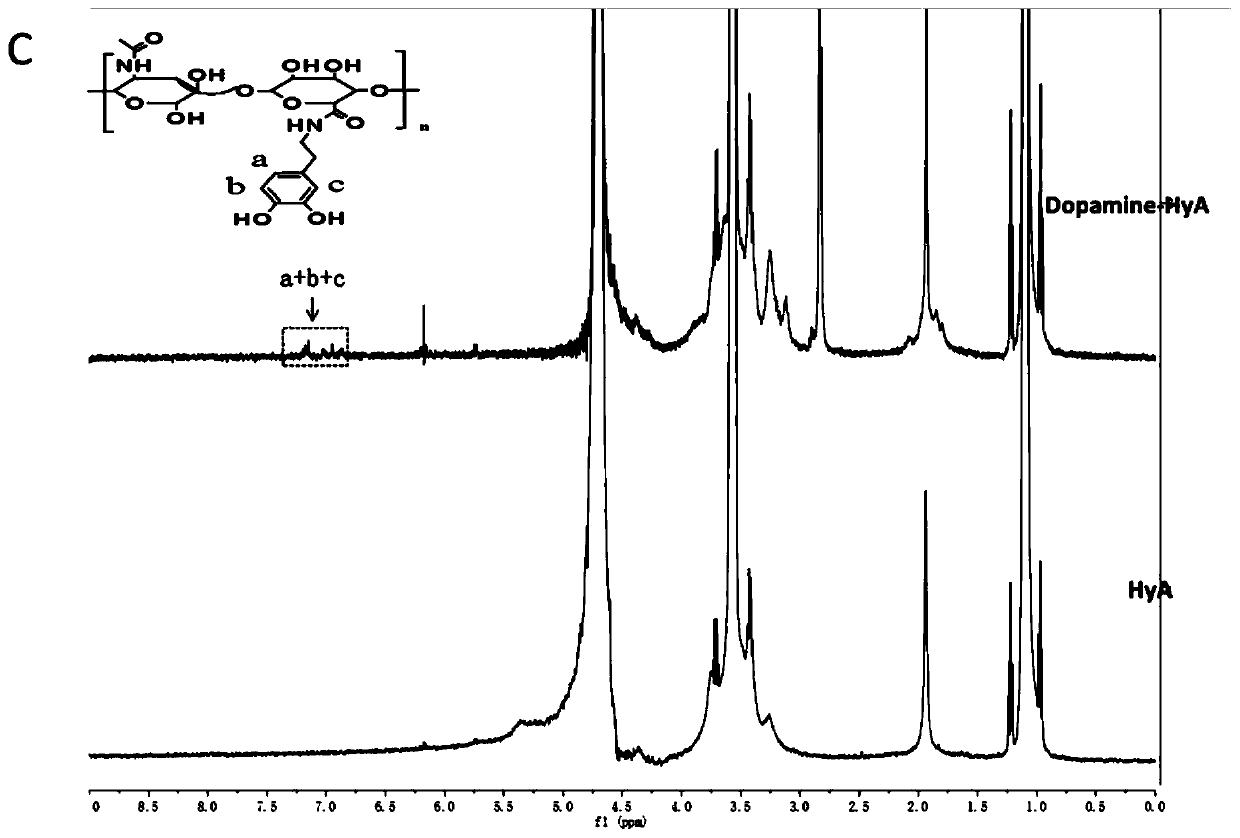

Embodiment 1

[0028]Taking the molar ratio of dopamine hydrochloride and hyaluronic acid as 1:1 as an example, 201.6 mg of hyaluronic acid was dissolved in 50 mL of deionized water, 191.7 mg of EDC and 115.09 mg of NHS were slowly added to the solution, stirred evenly for 20 min, and then added to Add 94.82 mg of dopamine hydrochloride to the mixed solution. The reaction solution was protected under nitrogen and stirred at room temperature, adjusted to pH 4 with hydrochloric acid, kept for 3 hours, and then continued to react overnight at room temperature. After the reaction, the solution was purified by dialysis (molecular weight cut-off = 12000Da) in an acidic environment of pH = 5 deionized water for 4 days, and dried in vacuum freezer (-70°C) for 72 hours to obtain a white flocculent graft product called dopamine-hyalurin Acid coating material, product mass 234.16mg. Change the feed ratio of dopamine hydrochloride and hyaluronic acid, and prepare coating materials under other condition...

Embodiment 2

[0033] Preparation of dentin tissue blocks: freshly extracted premolars for orthodontic treatment were fully sterilized with 2-5% sodium hypochlorite aqueous solution, and rinsed with PBS (phosphate buffered saline); then, the periodontal tissue was removed and applied PBS was cooled down to obtain the tooth root, and the pulp and predentin were completely removed, and the dentine tissue blocks of 3.0mm*3.0mm*1.0mm were cut under water spray cooling; all the dentine tissue blocks were soaked in deionized water for 5 hours in turn, Ultrasonic cleaning for 20 minutes, soaking in 17% EDTA aqueous solution for 101 minutes, soaking in 19% citric acid aqueous solution for 1 minute, and then disinfecting with 5.25% sodium hypochlorite aqueous solution for 30 minutes, then rinsing and soaking in PBS for 2 days, to obtain dentin tissue blocks.

[0034] The dopamine-hyaluronic acid coating material with a molar ratio of 1:1 was dissolved in 10 mL of deionized water at 25 mg, 50 mg and 10...

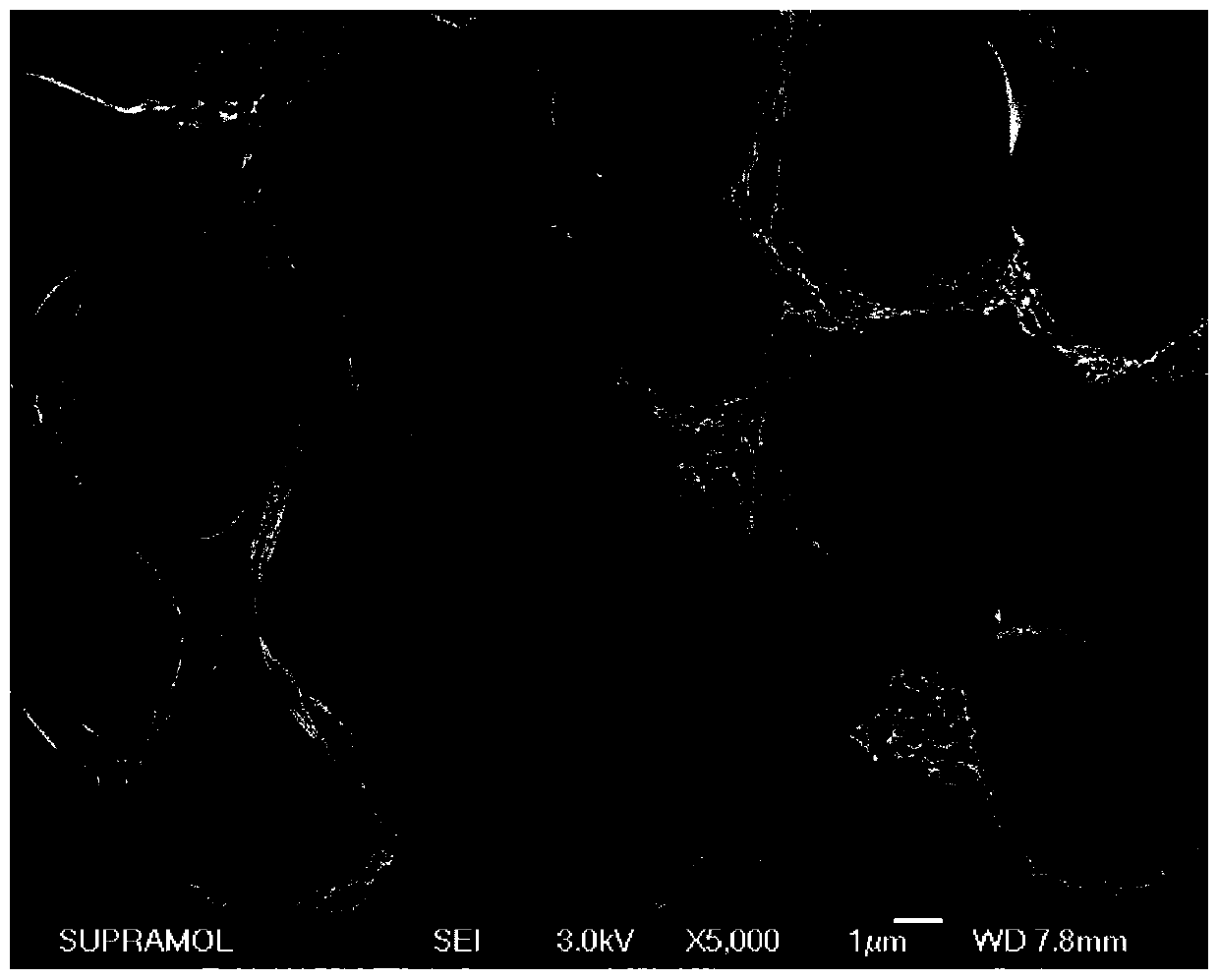

Embodiment 3

[0038] Select a dopamine-hyaluronic acid solution with a molar ratio of 5:1 and a concentration of 2.5 mg / mL, 5 mg / mL, and 10 mg / mL, and immerse the dentin tissue pieces prepared in Example 2 into the above solution, and take them out after 24 hours. Spin coating with a homogenizer (400r / s; 20s), and then transfer to a vacuum desiccator for freeze-drying for 48h. SEM observation of the micro-morphological characteristics of the dentin surface coating. The experimental data are listed in Table 3.

[0039] Table 3: Dentin coating data prepared with different concentrations of dopamine-hyaluronic acid solution at a molar ratio of 5:1

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com