Preparation method of high-specific surface area micro-nano cerium dioxide

A high specific surface area, ceria technology, applied in the field of nanomaterial manufacturing, can solve the problems of high production equipment requirements, affecting product quality, difficult operation, etc., to achieve the effect of low production cost, easy operation, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

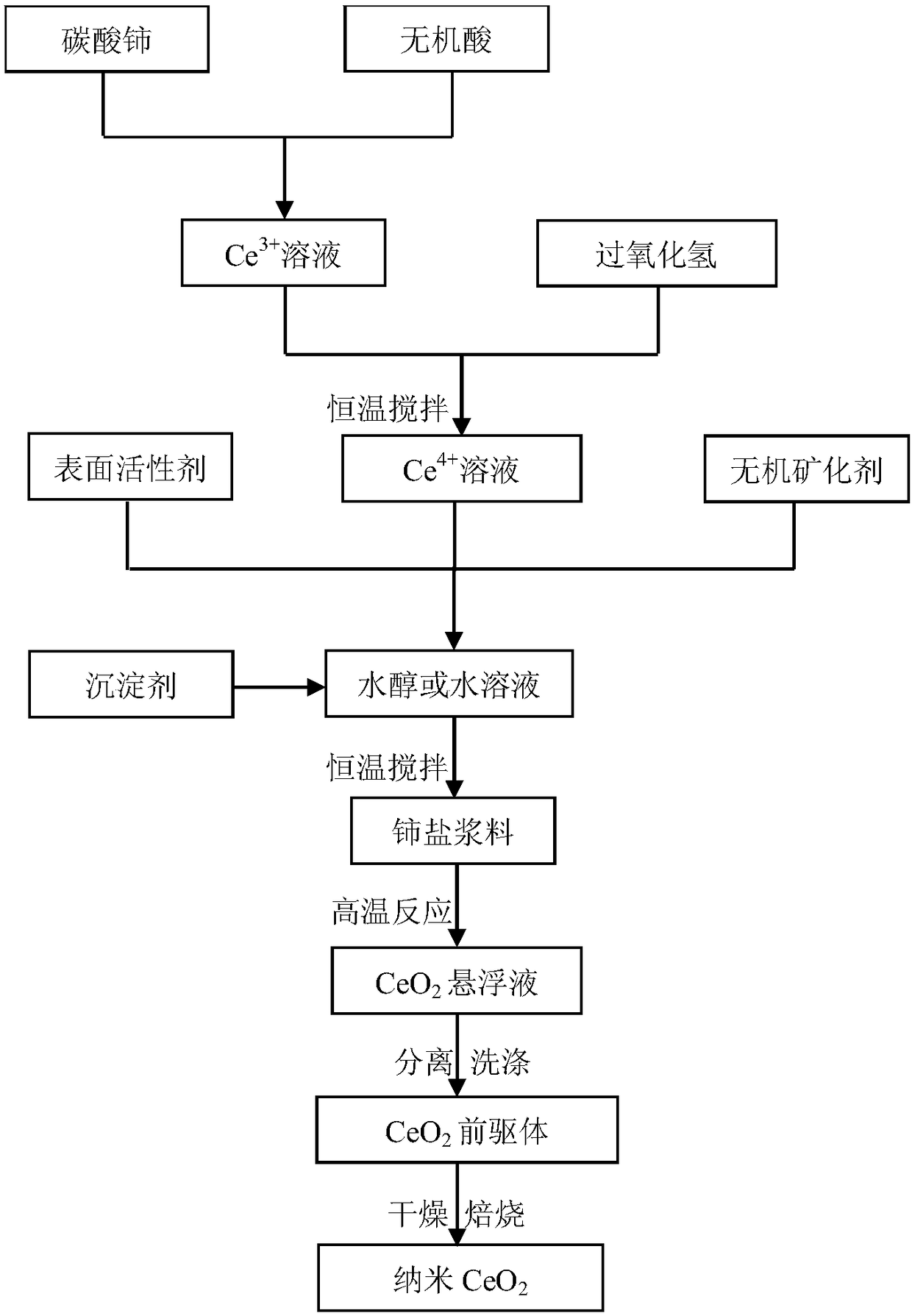

[0026] The preparation method adopted in some embodiments of the present invention is as follows: take cerium carbonate and dissolve it in inorganic acid, add inorganic salt mineralizer, surfactant and hydrogen peroxide, stir to form cerium salt solution (A solution), weigh the precipitate Prepare a precipitant solution (B solution), drop B solution at a rate of 1-3mL / min into A solution with a stirring rate of 200-500r / min, stir at a constant temperature of 25-80°C for 0.5h-5h, and form cerium salt Slurry, cerium salt slurry is hydrothermally reacted at 80-95°C for 2h-24h, centrifugally washed, oven-dried, ground, then roasted at 200-600°C for 1-3h, cooled to obtain nano cerium dioxide.

[0027] More preferably, the preparation method adopted in other embodiments of the present invention is as follows: weigh cerium carbonate and dissolve it in inorganic acid, weigh mineralizer and add it to the solution for dissolution, add hydrogen peroxide, and stir to form a cerium salt sol...

Embodiment 1

[0030]Weigh 18.2g of cerium carbonate, dissolve it in 14mL of concentrated nitric acid, add water to dilute to 50mL, and prepare a 1.6mol / L cerium nitrate solution, weigh 2.6g of potassium sulfate and add to the solution to dissolve, add 5mL of hydrogen peroxide, and stir for 5min to obtain (A liquid ), measure 16mL ammonia water and add 34mL aqueous solution containing 13.5g urea (B liquid), weigh 0.1g of cetyltrimethylammonium bromide and dissolve it in 88mL ethanol solution (C liquid), mix A liquid and B liquid At a rate of 3mL / min, drop it into liquid C with a stirring rate of 450r / min at the same time, and stir at 25°C for 30min to form a cerium salt slurry. The cerium salt slurry is hydrothermally reacted at 95°C for 4h, centrifugally washed, and dried in an oven. Drying, grinding, calcination in air at 500°C for 2 hours, and cooling to obtain nano-cerium dioxide. Specific surface area up to 164m 2 / g, the particle size is about 180nm.

Embodiment 2

[0032] Weigh 11.4g of cerium carbonate and dissolve it in 10mL of concentrated nitric acid, add water to dilute to 100mL, weigh 0.9g of potassium chloride and add to the solution to dissolve, add 5mL of hydrogen peroxide to prepare a 0.5mol / L cerium nitrate solution (liquid A), measure Take 36mL of ammonia water and add water to dilute to 100mL (solution B), weigh 4g of sodium lauryl sulfate and add it to a mixed solution containing 40mL of water and 10mL of ethanol to dissolve (solution C), and mix liquid A and liquid B simultaneously at a rate of 3mL / min. Drop into liquid C with a stirring rate of 450r / min, stir at 25°C for 4h, undergo a hydrothermal reaction at 80°C for 4h, centrifugally wash, dry in an oven, grind, then roast in air at 300°C for 2h, and cool to obtain di Ceria. Specific surface area up to 172m 2 / g, the particle size is about 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com