Preparation method of titanium oxide/calcium oxide/silicon oxide composite photocatalytic material in hollow structure

A composite photocatalysis and silicon oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve problems such as environmental pollution, achieve strong operability, Wide application prospects, the effect of accelerating the rate of chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

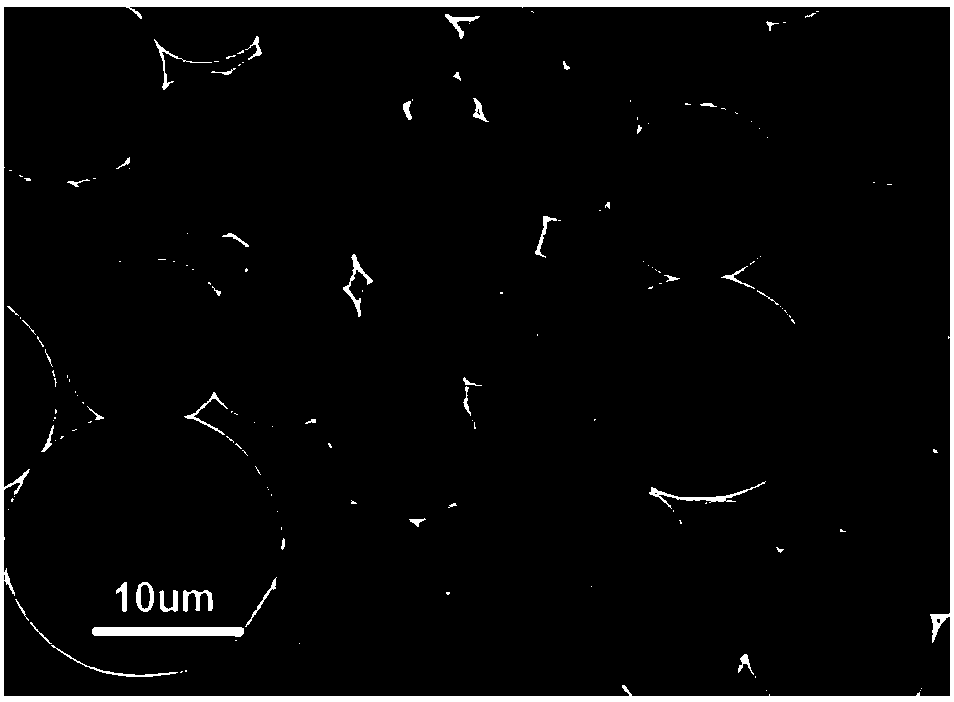

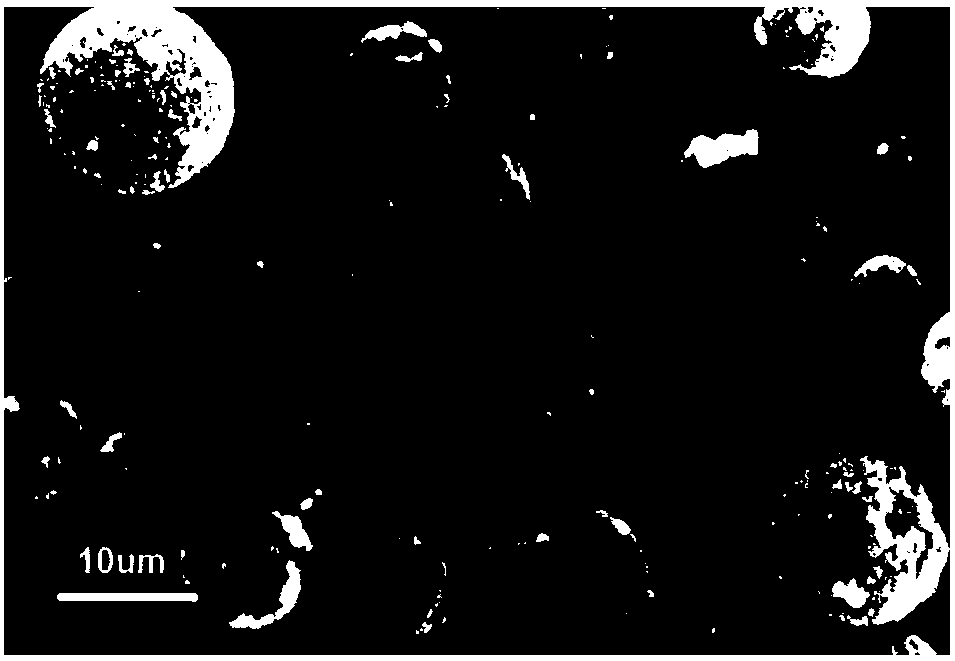

Image

Examples

preparation example Construction

[0030] The preparation method according to the present invention adopts TiO 2 And CaO as the core material, the outer wrapping SiO 2 The scheme effectively realizes the decomposition of NOx, and at the same time ensures that the organic resin material of the coating base material will not be corroded. Among them, CaO, as the core material, has a strong basicity, which can be combined with the NO produced by the photocatalytic process. 3 - The root ions react to form Ca(NO 3 ) 2 , not only can accelerate the chemical reaction rate of the photocatalytic process, but also avoid HNO 3 Corrosion to the base.

[0031] In addition, the porous structure of the silica shell itself can absorb gaseous pollutants and speed up the reaction rate. At the same time, it can isolate the oxidation reaction center from the organic substrate to prevent base corrosion, and can also avoid the volume change of the active filler calcium oxide during the chemical reaction. And acid-base changes d...

Embodiment 1

[0039] 1) Add 0.1 mol of titanium tetrachloride dropwise to 1000ml of pure water in an ice-water bath to obtain Ti 4+ Ion concentration is in the titanium liquid of 0.1mol / L, then adds analytically pure calcium chloride 0.56g thereinto, obtains Ca 2+ Ca / Ti composite solution with an ion concentration of 0.5mol / L, Ti 4+ Ions and Ca 2+ The molar ratio of ions is 1:5;

[0040] 2) Add 10ml of hydrogen peroxide with a mass percentage of 30% to it to obtain an orange solution, and then dropwise add 10 ml of ammonia water with a mass percentage of 10% to obtain an emulsion;

[0041] 3) Add 500ml of ethanol to the emulsion again, under the condition of vigorous stirring at room temperature, add 2ml of 5ml of tetrahexyloxysilane with a volume percentage of 37.5% dropwise, the organic silane compound and the titanium / calcium-peroxide-ammonia compound are slightly The mass ratio of the balls is about 1:3, and the reaction takes 12 hours.

[0042] 4) The reaction product was centrifug...

Embodiment 2

[0044] Except Ti in step 1) 4+ Ions and Ca 2+ The molar ratio of ions was controlled to be 1:8, and the titanium oxide / calcium oxide / silicon oxide composite photocatalytic material was prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com