Fish bait with advantages of controlled release and gas generation

A bait, water-insoluble technology, applied in the field of fishing supplies, can solve the problems of inconvenience in carrying and use, large amount of bait, waste, etc., and achieve the effects of remarkable technological progress, small amount of bait, and convenient carrying and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The preparation steps of the bait of this embodiment are as follows in sequence:

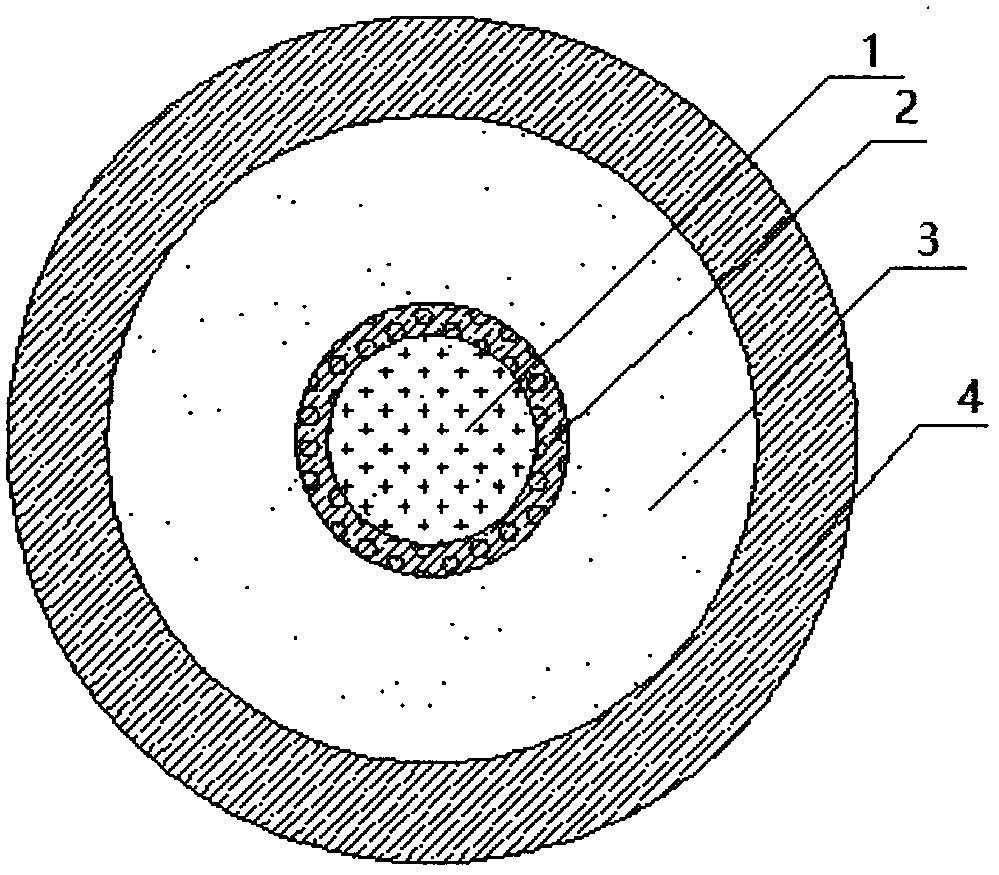

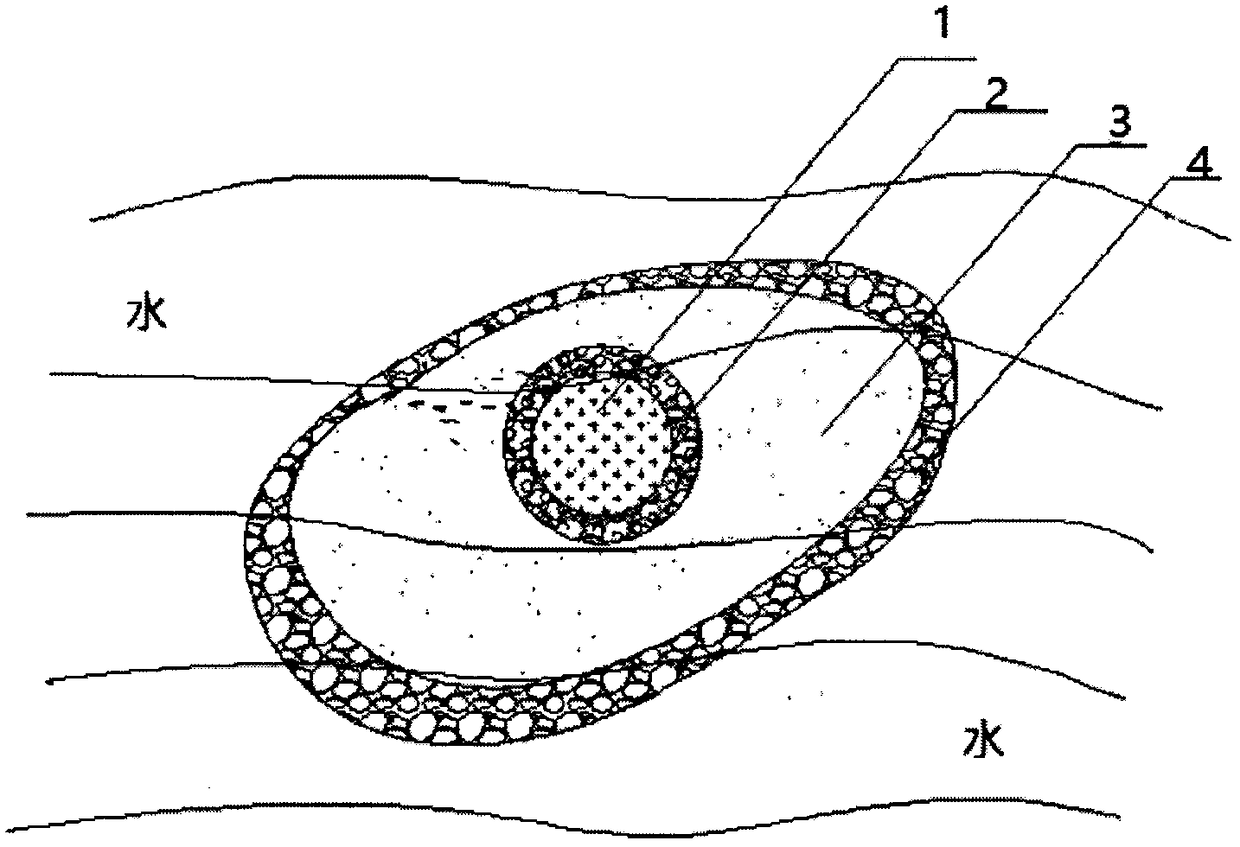

[0022]The formula of spherical core 1 is: 0.5g thiobetaine, 0.5g amino acid complex, 0.5g vanillin, 0.5g ethyl maltol, 0.3g citric acid, 0.3g malic acid, 0.3g tartaric acid, succinic acid 0.3g, filler 5.0g, essence 2.0g, binder 10.0g.

[0023] The formula of the water-insoluble microporous coating film 2 is: 5.0 g of ethyl cellulose, 50 g of ethyl acetate, 0.4 g of diethyl phthalate, and 0.2 g of sodium chloride.

[0024] The formula of the state maintaining layer 3 is: 3.0 g of calcium peroxide, 4.0 g of sodium carboxymethyl cellulose, 4.0 g of sodium alginate, 3.0 g of modified starch, 3.0 g of carrageenan, 3.0 g of soybean powder, and 1.5 g of sodium carbonate.

[0025] The formula of rapid atomization layer 4 is: 1.0g of pregelatinized starch, 3.0g of soaked millet, 3.0g of wheat germ, 4.0g of soybean textured protein granules, 0.3g of titanium dioxide, and 25g of water...

Embodiment 2

[0029] The formula of spherical ball core 1 is: 2.0g of amino acid compound, 0.9g of citric acid, 5.0g of filler, 2.0g of essence, and 10.0g of binder.

[0030] The formula of the water-insoluble microporous coating film 2 is: 5.0 g of ethyl cellulose, 50 g of ethyl acetate, 0.4 g of diethyl phthalate, and 0.2 g of glucose.

[0031] The formula of the state maintaining layer 3 is: 3.0 g of calcium peroxide, 14.0 g of sodium carboxymethyl cellulose, 3.0 g of soybean powder, and 1.5 g of sodium carbonate. The formula of rapid atomization layer 4 is: 1.0g of pregelatinized starch, 3.0g of soaked millet, 3.0g of wheat germ, 4.0g of soybean textured protein granules, 0.3g of titanium dioxide, and 25g of water.

[0032] According to the ratio of various substances in the above-mentioned layers, the raw materials used for preparing each layer are weighed.

[0033] Mix the amino acid compound, citric acid, filler, essence and binder that were weighed to prepare the spherical pellet c...

Embodiment 3

[0035] The formula of spherical pellet core 1 is: 2.0g of amino acid compound, 0.9g of citric acid, 2.0g of essence, 5.0g of wetting agent, and several blank pellet cores.

[0036] The formula of the water-insoluble microporous coating film 2 is: 5.0 g of cellulose acetate, 50 g of ethyl acetate, 0.4 g of diethyl phthalate, and 0.2 g of sodium chloride.

[0037] The formula of the state maintaining layer 3 is: 3.0 g of calcium peroxide, 14.0 g of sodium carboxymethyl cellulose, 3.0 g of soybean powder, and 1.5 g of sodium carbonate. The formula of rapid atomization layer 4 is: 1.0g of pregelatinized starch, 3.0g of soaked millet, 3.0g of wheat germ, 4.0g of soybean textured protein granules, 0.3g of titanium dioxide, and 25g of water.

[0038] According to the ratio of various substances in the above-mentioned layers, the raw materials used for preparing each layer are weighed.

[0039] The spherical blank ball core is used as the carrier and seed carrying the food attractant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com