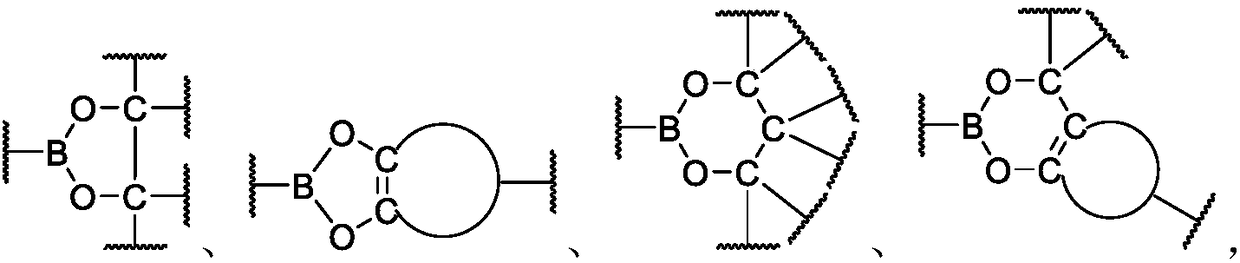

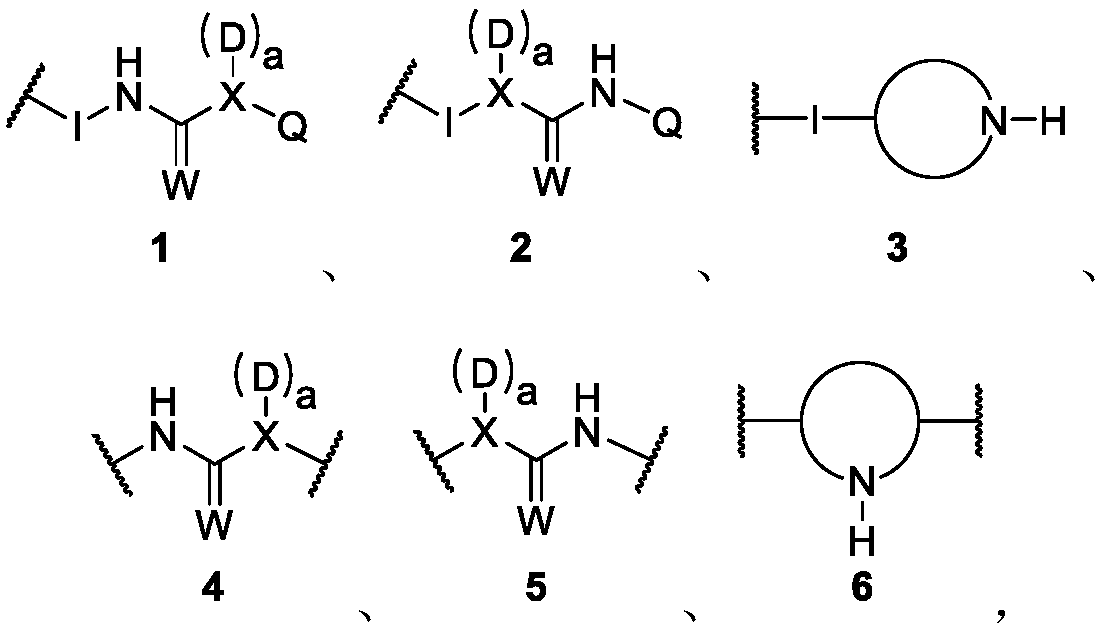

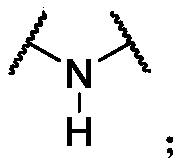

Hybrid dynamic polymer and application thereof

A technology of polymers and compounds, applied in the field of intelligent polymers, can solve the problems that the characteristics of dynamic reversible covalent bonds are difficult to be fully reflected, and achieve the effects of easy recycling and reuse, self-repair, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0259] In the preparation process of hybrid dynamic polymers, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0260] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it gel and solidify to become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0261] Wherein, the physical foaming method is to utilize physical principles to realize the foaming of the polymer in the preparation process of the dynamic polymer, which generally includes the following four methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material unde...

Embodiment 1

[0317]

[0318]Add 5g of diaminomethylphenylboronic acid compound into the three-necked flask (using 2-aminomethylphenylboronic acid and 1,6-hexamethylene diisocyanate as raw materials, controlling the molar ratio of the two to 2:1, and reacting at room temperature) , 30g polyol compound (a) (with propylene glycol, 2-methyl-2-propyl [3-(2-oxiranyl) propyl] carbamate as raw material, boron trifluoride ether as catalyst , through cationic ring-opening polymerization to synthesize a propylene oxide copolymer with a carbamate group in the side group; prepared by reaction), add 200ml of toluene solvent, heat to 60°C for stirring and dissolving, after mixing for 30min, then add 2ml of triethylamine dropwise, and continue to stir and react. The apparent viscosity of the polymer fluid is tested using a rotational viscometer, wherein the test temperature is 25°C and the shear rate is constant at 0.1s -1 , the apparent viscosity of the polymer fluid was measured to be 17,946 mPa·s. ...

Embodiment 2

[0320]

[0321] In the three-necked flask, add 30g of phenylboronic acid double-capped polytetrahydrofuran (using 4-aminophenylboronic acid as a raw material, and dibromo-capped polytetrahydrofuran with potassium carbonate as a catalyst to obtain through alkylation reaction), 3.8g of polytetrahydrofuran Alcohol compound (a) (using AIBN as the initiator and triethylamine as the catalyst, using 1,3,5-triacryloylhexahydro-1,3,5-triazine and quantitative N-[(2-mercapto Ethyl)carbamoyl]propionamide and 3-mercapto-1,2-propanediol are prepared by thiol-alkene click addition reaction), add a small amount of BHT antioxidant dropwise, heat to 120°C and mix and stir for 30min, Add a small amount of triethylamine dropwise, react for 3 hours under nitrogen protection, then pour the viscous reaction solution into a suitable mold, place it in a vacuum oven at 80°C for 24 hours for further reaction, then cool to room temperature and place it for 30 minutes, and finally The obtained polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com