Preparation method for visible light photocatalyst powder and cloth from bismuth-rich material

A photocatalyst and visible light technology, which is applied in the field of material chemistry and photocatalysis, can solve the problems of secondary pollution and difficult recycling, and achieve the effect of clean surface, uniform particle shape and size, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing visible light catalyst powder and "cloth" from bismuth-rich materials is as follows: 10mmol bismuth chloride and 0.5mmol cobalt chloride are dissolved in 200mL edetate disodium aqueous solution (0.15mol / L), and 35mmol sodium diethyldithiocarbamate trihydrate was dissolved in 100mL of water, then added dropwise to the bismuth-rich solution, and a precipitate was gradually produced, after the addition was completed, filtered, then added with 300mL of water, filtered, washed and dried to obtain 5% cobalt doped bismuth diethyldithiocarbamate powder. Dissolve 200 mg of the prepared powder in 5 mL of N,N-dimethylformamide, add 500 mg of polyacrylonitrile, and apply a voltage of 15 kV for electrospinning to obtain 5% cobalt-doped bismuth diethyldithiocarbamate Catalytic "cloth".

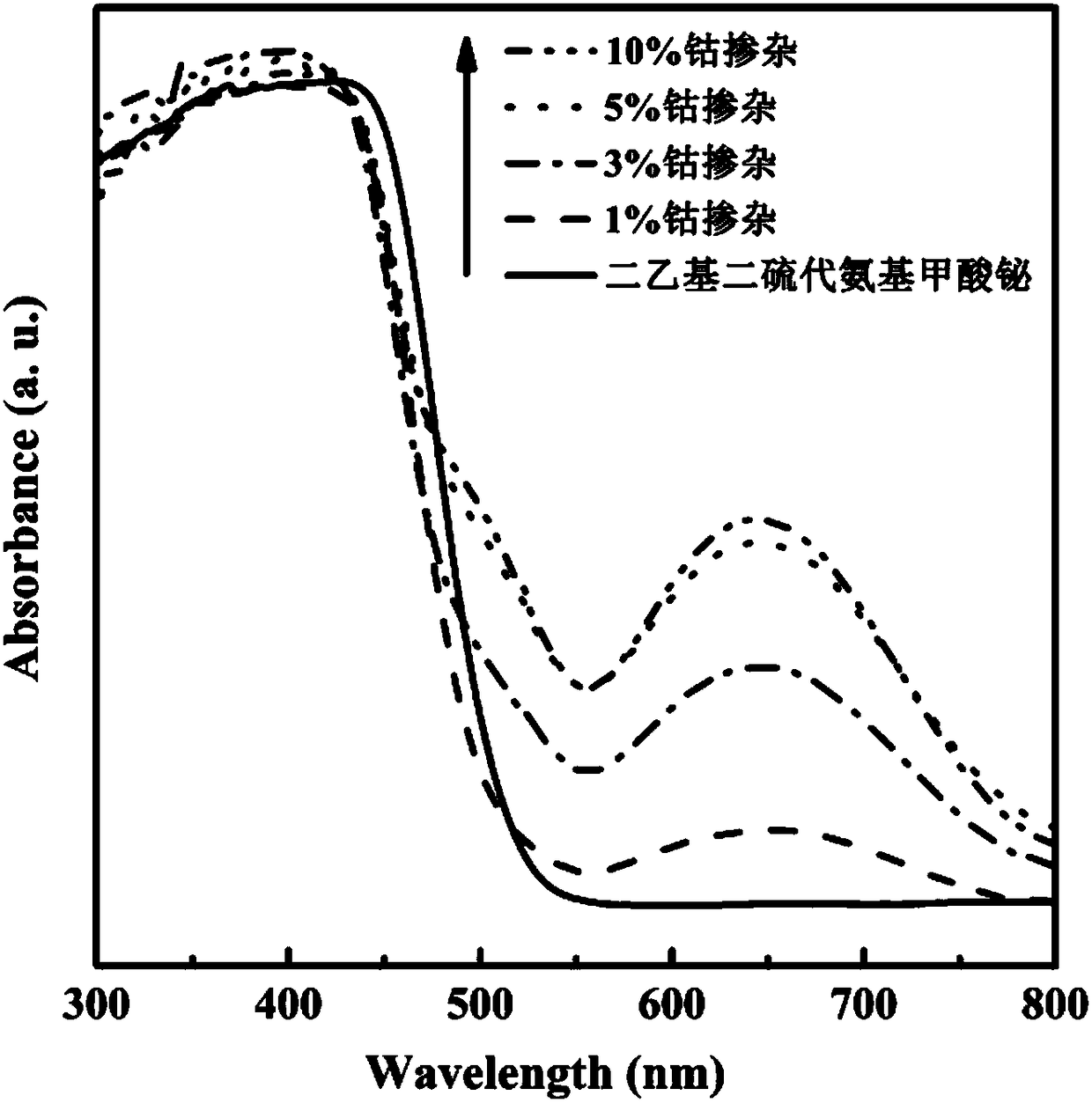

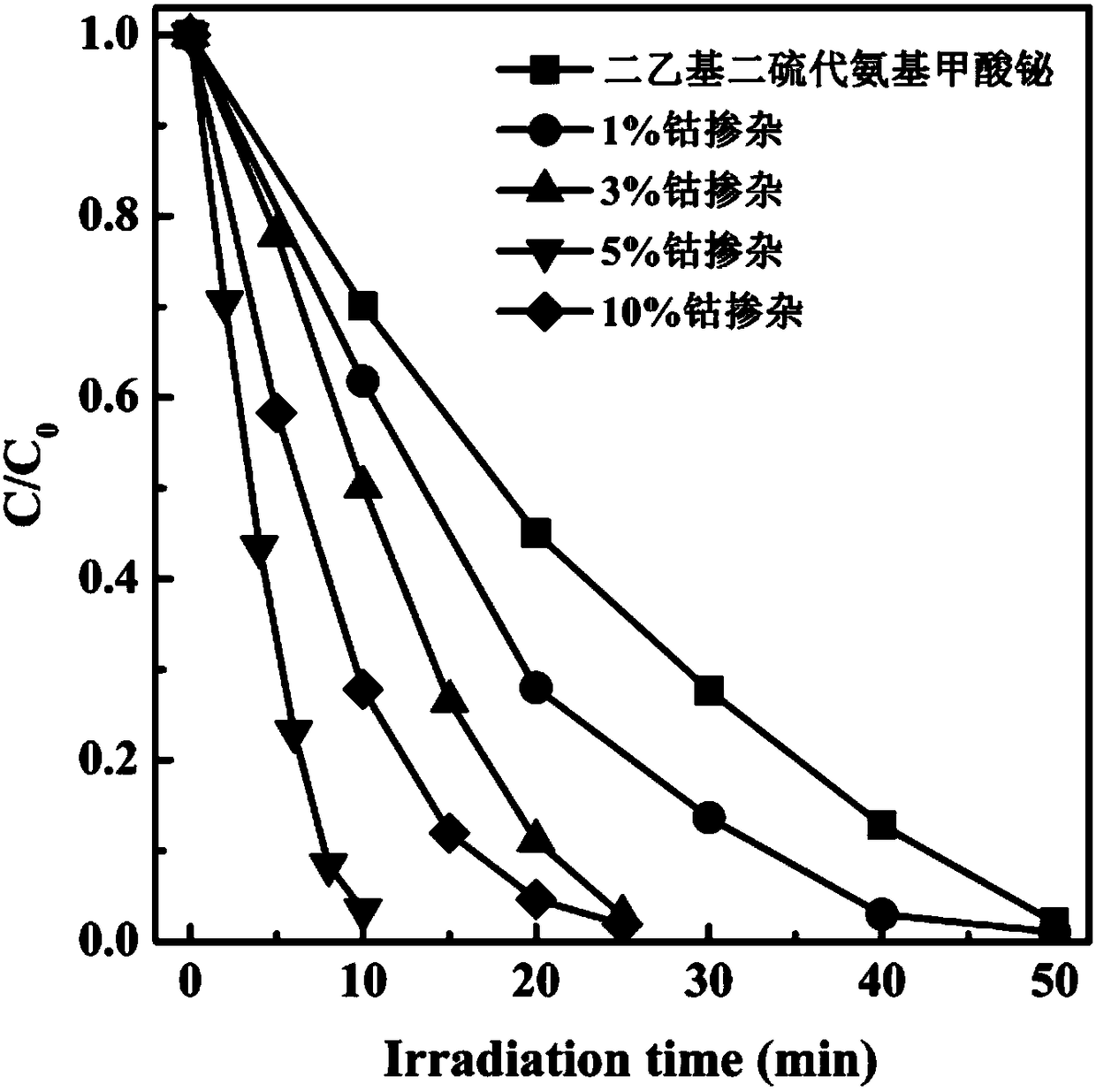

[0038] Observe that this powder product is the box that surface has nanoporous structure with scanning electron microscope, and size is about 10 μ m (see figure 1 ); detected...

Embodiment 2

[0040] A method for preparing visible light catalyst powder and "cloth" from bismuth-rich materials is as follows: 10mmol bismuth neododecanoate, 0.5mmol nickel acetate and 0.5mmol manganese acetate are dissolved in 200mL ethanol (adjust the pH to less than 2 with hydrochloric acid), Dissolve 40mmol of ammonium diethyldithiocarbamate in 100mL of ethanol, then add it dropwise to the bismuth-rich solution, and gradually produce a precipitate. After the dropwise addition, filter, then add 300mL of water, filter, wash and dry to obtain 5% nickel 5% manganese doped bismuth diethyldithiocarbamate powder. Dissolve 200 mg of the prepared powder in 5 mL of chloroform, add 500 mg of polystyrene, and apply a voltage of 20 kV for electrospinning to obtain a 5% nickel 5% manganese-doped bismuth diethyldithiocarbamate photocatalyst "cloth". ".

Embodiment 3

[0042] A method for preparing visible light catalyst powder and "cloth" from bismuth-rich materials is as follows: 10mmol bismuth acetate, 0.3mmol ferrous chloride, 0.1mmol cupric chloride and 0.1mmol cerous chloride are dissolved in 200mL formamide ( Use sulfuric acid to adjust the pH to be less than 2), dissolve 35mmol diethylammonium diethyldithiocarbamate in 100mL formamide, then add dropwise in the rich bismuth solution, gradually produce precipitation, after the dropwise addition, filter, and then Add 300 mL of water, filter, wash and dry to obtain 3% iron 1% copper 1% cerium doped bismuth diethyldithiocarbamate powder. Dissolve 200 mg of the prepared powder in 5 mL of N,N-dimethylformamide, add 500 mg of polyvinylidene fluoride, and apply a voltage of 15 kV for electrospinning to obtain 3% iron, 1% copper, 1% cerium-doped diethyl diethylene difluoride Bismuth thiocarbamate photocatalytic "cloth".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com