Antibacterial and environment-friendly ecological putty and preparation method thereof

An ecological and putty technology, applied in the direction of filling slurry, etc., can solve the problems of easy growth of mold, affecting the performance of wall coatings, poor bacteriostatic properties, etc., and achieves excellent bacteriostatic and antibacterial properties, short maintenance period, and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

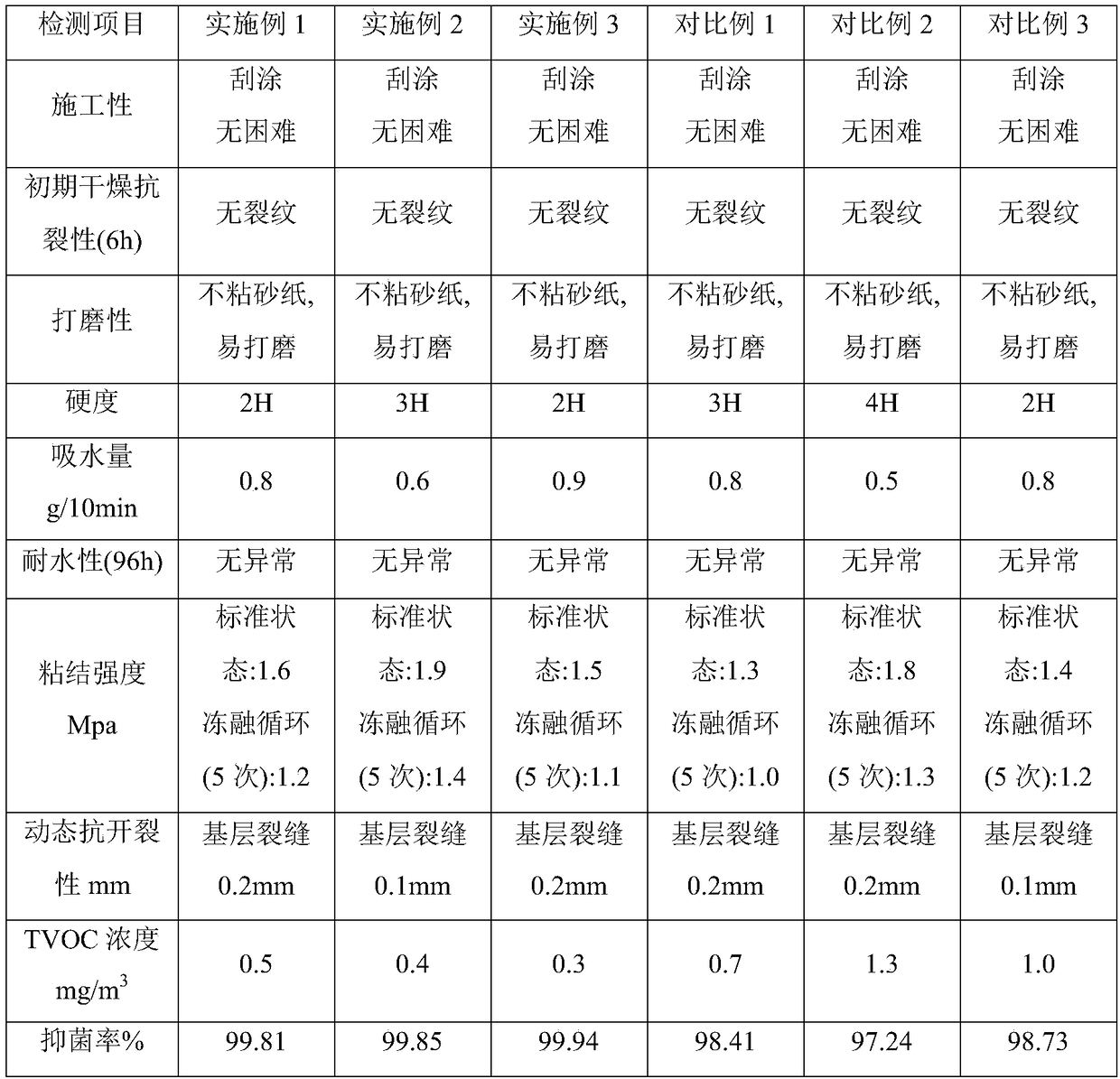

Examples

Embodiment 1

[0024] An antibacterial and environmentally friendly ecological putty, which is made of the following raw materials in parts by weight: 50 parts of ash calcium powder with a particle size of 50 μm, 50 parts of quartz powder with a particle size of 50 μm, 5 parts of osmanthus gemstone, 5 parts of magnetic wave stone, acetic acid 8 parts of vinyl ester homopolymer rubber powder, 6 parts of ammonium polyacryloyl dimethyl taurate, 5 parts of hydroxypropyl distarch phosphate, 2 parts of dodecyl alcohol ester, 2 parts of propylene glycol phenyl ether, the particle size is 50 μm 3 parts of silver-loaded zirconium phosphate, 2 parts of tallow diamine dioleate.

[0025] A preparation method for antibacterial and environmentally friendly ecological putty, comprising the following steps:

[0026] (1) Use mechanical impact mill to pulverize osmanthus gemstones and magnetic wave stones to control their particle size d 97 = 5-7 μm, then add polyacryloyl dimethyl ammonium taurate, hydroxypr...

Embodiment 2

[0030] An antibacterial and environmentally friendly ecological putty, which is made of the following raw materials in parts by weight: 60 parts of heavy calcium powder with a particle size of 80 μm, 40 parts of lime powder with a particle size of 80 μm, 5 parts of Tianshou stone, 5 parts of loess stone, 11 parts of vinyl acetate and ethylene copolymer powder, 5 parts of sodium hexametaphosphate, 4 parts of 2-amino-2-methyl-1-propanol, 4 parts of sodium starch octenyl succinate, 4 parts of Indian gum, ten 2 parts of dicarbonyl alcohol ester, 3 parts of propylene glycol phenyl ether, 2 parts of soluble silver-loaded glass with a particle size of 80 μm, 2 parts of silver-loaded silica gel with a particle size of 80 μm, N-propyl-perfluorooctane sulfonamide Potassium glutamate 2 parts, sodium lauryl sulfate 1 part.

[0031] A preparation method for antibacterial and environmentally friendly ecological putty, comprising the following steps:

[0032] (1) Use mechanical impact mill ...

Embodiment 3

[0036] An antibacterial and environmentally friendly ecological putty, which is made of the following raw materials in parts by weight: 100 parts of ash calcium powder with a particle size of 100 μm, 5 parts of magnetic wave stone, 16 parts of styrene and butadiene copolymer rubber powder, inulin lauryl 12 parts of carbamate, 10 parts of konjac glucomannan, 3 parts of lauryl alcohol ester, 4 parts of propylene glycol phenyl ether, 2 parts of silver-loaded zeolite with a particle size of 100 μm, and 4 parts of alkyl glycoside.

[0037] A preparation method for antibacterial and environmentally friendly ecological putty, comprising the following steps:

[0038] (1) Use a mechanical impact mill to pulverize the magnetic wave stone to control its particle size d 97 = 5-7 μm, then add inulin lauryl carbamate and konjac glucomannan to it, and stir and mix for 4 minutes at a speed of 400 r / min to obtain a mixture A;

[0039] (2) Mix lime calcium powder, styrene and butadiene copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com