Preparation method of diamine monomer based on biomass raw materials

A biomass raw material, diamine monomer technology, applied in organic chemistry and other directions, can solve the problems of poor solubility, low transparency, inability to withstand high temperature, etc., and achieve the effects of good solubility, good thermal stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

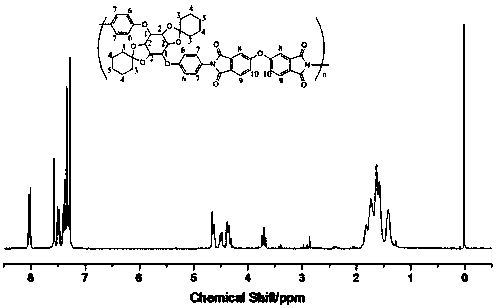

Image

Examples

Embodiment 1 2

[0033] Embodiment 1 Diamine monomer material preparation

[0034] Preparation of compound 1:

[0035] 3g (16.7mmol) myo-inositol, 10mL (66.6mmol) 1,1'-dimethoxycyclohexane, 0.329g (1.73mmol) p-benzenesulfonic acid were reacted in 20mL DMF solution at 100°C for 12 hours, Then add 0.7mL triethylamine, dilute the reaction solution with 70mL ethyl acetate after concentration, then wash with 5% sodium bicarbonate solution, dry the organic layer with anhydrous sodium sulfate for 12h, filter the organic layer and spin dry to obtain a viscous solid , recrystallized twice in a mixed solution of ethyl acetate: n-hexane = 1:1 to obtain 0.85 g of white crystals. (yield 15%)

[0036] Preparation of compound 2:

[0037] Mix 3.4g (10mmol) white crystals of compound 1 with 3.53g (25mmol) p-fluoronitrobenzene, 0.53g (2mmol) 18-crown-6, 1.68g (30mmol) potassium hydroxide in 20mL DMF and 12mL toluene The solution was reacted at 135°C for 12 hours to obtain a golden yellow solution, and the r...

Embodiment 2

[0056] The preparation (microwave method) of embodiment 2 polymer films

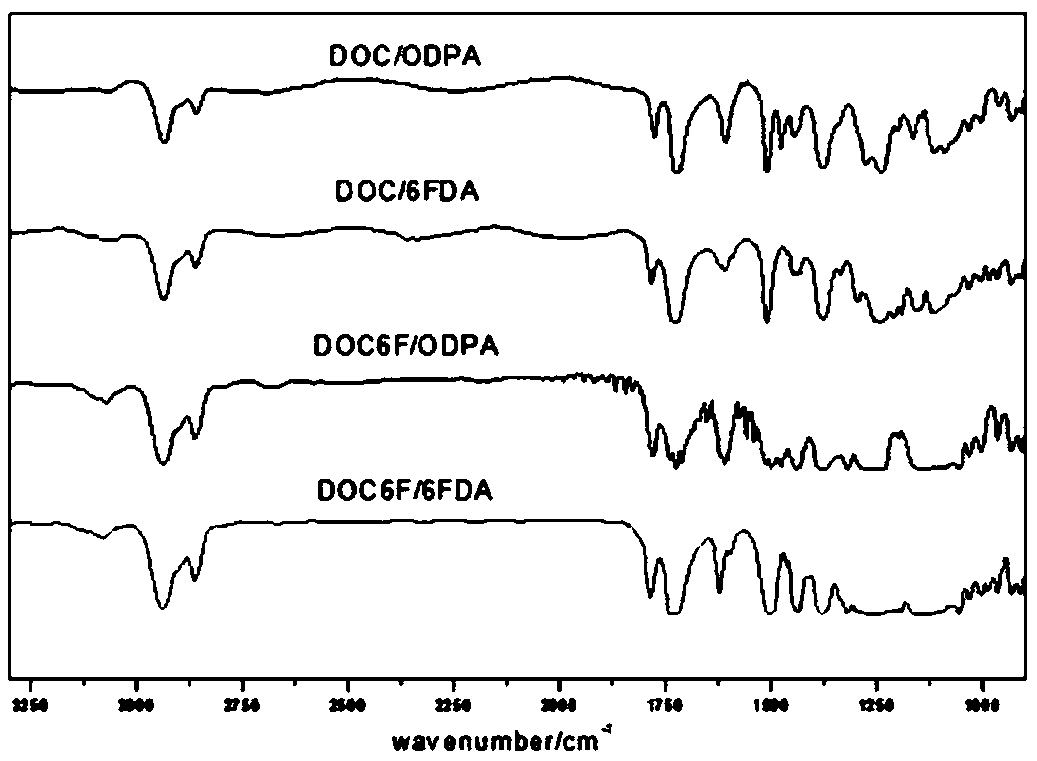

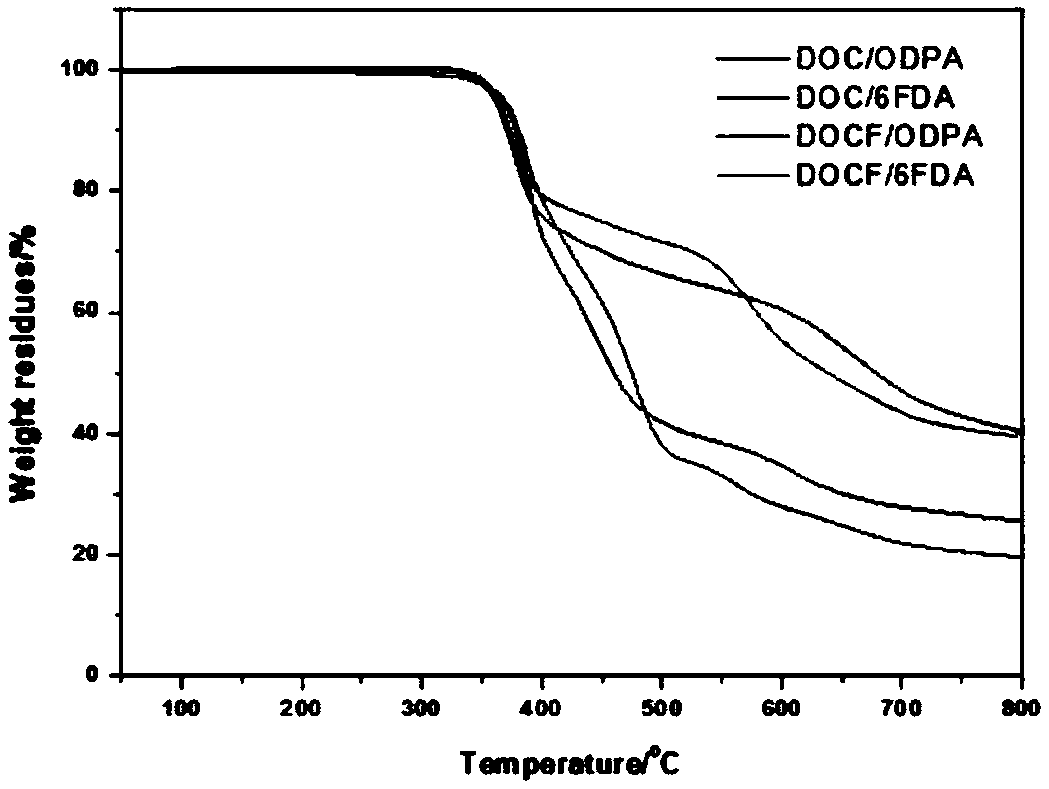

[0057] The two diamine monomers M1 and M2 react with dianhydride monomers 4,4'-diphenyl ether dianhydride (ODPA) and 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA), respectively, A series of PI thin films were obtained. In order to describe its usual synthetic route, PI-1(M1 / ODPA) was taken as an example.

[0058] 0.2274 g of ODPA was added to 3 mL of m-cresol dissolved with 0.3867 g of compound M1 and 10 drops of isoquinoline under anaerobic conditions. An additional 2 mL of m-cresol was added to adjust the solids content of the solution to 12%. The mixture was placed in a glass tube and carried out a two-step polymerization operation through a microwave reactor, reacted at 80 °C for 30 min to obtain PAA, and then reacted at 200 °C for 1 h to obtain PI.

[0059] After the reaction, the golden viscous solution was slowly poured into absolute ethanol to settle a white PI solid. The sediment ...

Embodiment 3

[0075] Solubility test:

[0076] The solubility of the polyimide film was tested in a series of different solutions at a concentration of 10 mg / mL. The results showed that all myo-inositol-derived polyimide films showed good solubility properties in a series of polar and non-polar film solvents and even low boiling point solvents such as methylene chloride / tetrahydrofuran / acetone. The analysis is mainly due to the bulky cyclohexyl side group in the biomass diamine monomer, which makes it easier for solvent molecules to penetrate into the molecular chain and between the chains. On the other hand, the bulky side group provides more free volume, and on the other hand, it can also reduce the chain-chain force by reducing the tight packing within and between the molecular chains. Also, polymers containing trifluoromethyl group showed better solubility. The research results show that myo-inositol-derived polyimides have good solubility and preparation capabilities, making them hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Solution temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com