Biomass pellet feed for ruminants and preparation method thereof

A technology of biomass pellets and ruminants, applied in animal feed, animal feed, application, etc., can solve the problems of low feed degree and protein content, inability to guarantee the freshness of silage, and low animal digestion and absorption rate, etc., to improve Effects of digestion and absorption rate, shortening silage fermentation period, and increasing animal feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

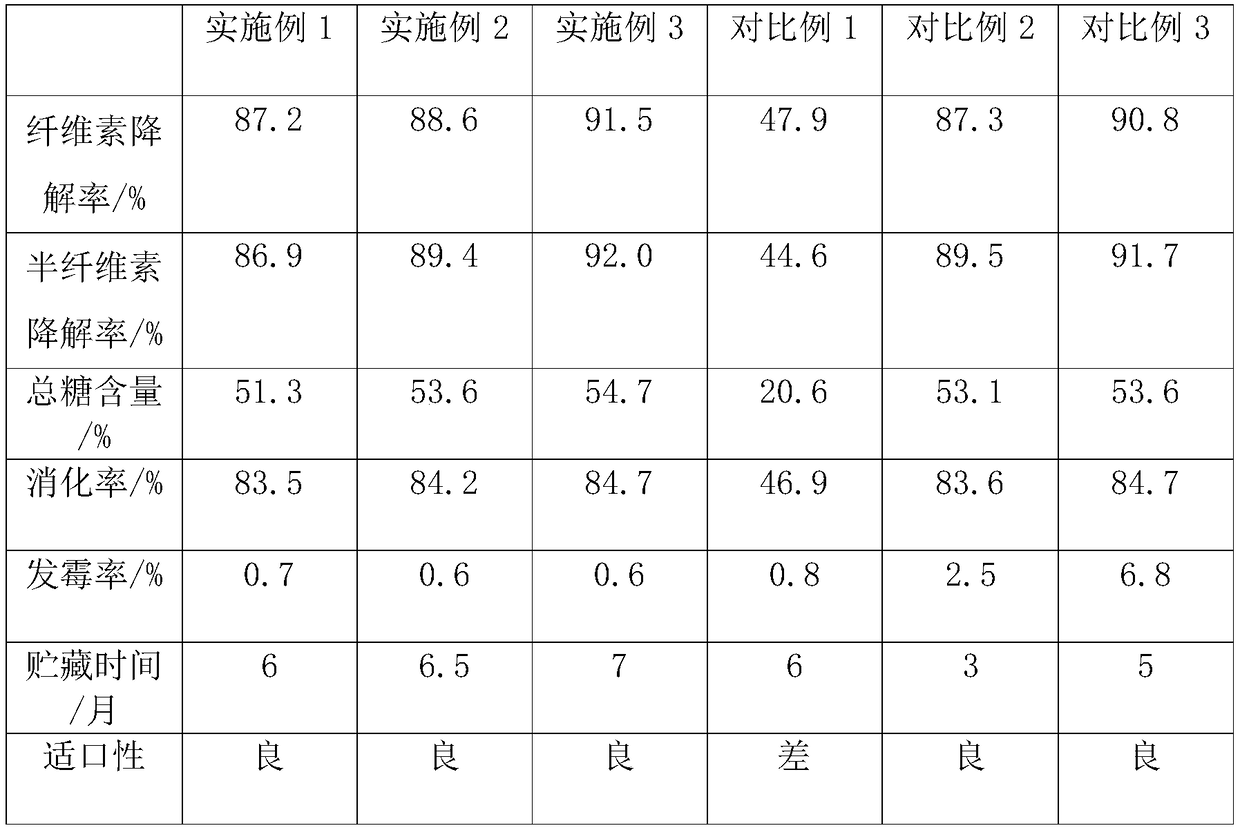

Examples

Embodiment 1

[0027] A biomass pellet feed for ruminants, comprising the following components in parts by weight: 32 parts of corn stalks, 18 parts of corn cobs, 27 parts of sweet potato stalks, 16 parts of ryegrass, 21 parts of beer tanks, 11 parts of egg shells, and 20 parts of soybean meal , 0.7 parts of preservatives, 2 parts of antioxidants, 0.6 parts of choline chloride.

[0028] The present invention also provides a preparation method of the above-mentioned biomass granular carbon-based fertilizer, comprising the following steps:

[0029] Step 1: Cut corn stalks, corn cobs, sweet potato stalks and ryegrass to a length of 0.5 cm, add 2.4% ammonia water, 4% calcium hydroxide solution and 3% carbonamide peroxide solution, and jointly impregnate them for 8 hours, then pass through 2.4MPa steam explosion treatment for 3 minutes to obtain pretreated biomass material;

[0030] Step 2: Mix Candida utilis, Lactobacillus, and Bacillus coagulans according to the weight ratio of 1:1:1, wherein ...

Embodiment 2

[0034] 36 parts of corn straw, 21 parts of corn cob, 30 parts of sweet potato straw, 21 parts of ryegrass, 23 parts of beer tank, 13 parts of egg shell, 22 parts of soybean meal, 1.0 part of preservative, 3 parts of antioxidant, 0.9 part of choline chloride .

[0035] Preparation method is with embodiment 1, difference is:

[0036] Step 1: The cut-off length is 0.75cm, the concentrations of ammonia water, calcium hydroxide solution and carbonamide peroxide solution are 2.7%, 5% and 4% respectively, the immersion time is 10h, the steam pressure is 3MPa, and the blasting treatment time is 4min;

[0037] Step 2: The number of live bacteria of Candida utilis, Lactobacillus and Bacillus coagulans reached 5.3×10 9 CFU / g, 1.05×10 9 CFU / g, 3.4×10 9 CFU / g, water content of 45%, PH of 7.0, mixed bacteria inoculum of 6%wt, silage fermentation temperature and days of 35°C, 19d;

[0038] Step 3: the preservative is sodium benzoate, the weight ratio of the components of the antioxidant ...

Embodiment 3

[0041] 40 parts of corn stalks, 24 parts of corn cobs, 33 parts of sweet potato stalks, 26 parts of ryegrass, 25 parts of beer tank, 15 parts of egg shells, 24 parts of soybean meal, 1.3 parts of preservatives, 4 parts of antioxidants, 1.2 parts of choline chloride .

[0042] Preparation method is with embodiment 1, difference is:

[0043] Step 1: the cut-off length is 1cm, the concentrations of ammonia water, calcium hydroxide solution and carbonamide peroxide solution are 3%, 6% and 5% respectively, the immersion time is 12h, the steam pressure is 3.6MPa, and the blasting treatment time is 5min;

[0044] Step 2: The number of live bacteria of Candida utilis, Lactobacillus and Bacillus coagulans reaches 1×10 10CFU / g, 2×10 9 CFU / g, 6×10 9 CFU / g, the water content is 50%, the pH is 7.2, the inoculation amount of mixed bacteria is 7%wt, the temperature and days of silage fermentation are 38°C and 23d;

[0045] Step 3: the preservative is nisin, the weight ratio of the compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com