Escherichia coli engineering bacterium for producing 2,3,5,6-tetramethylpyrazine and application thereof

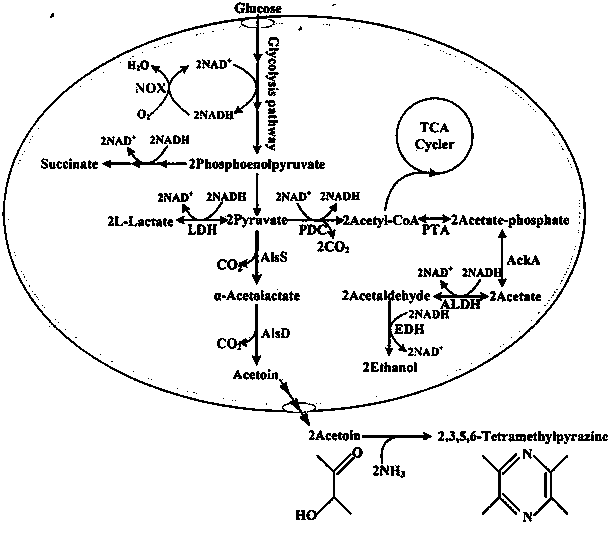

A technology of tetramethylpyrazine and engineering bacteria, applied in the direction of microorganism-based methods, bacteria, microorganisms, etc., can solve the problems of many by-products and high requirements for reaction conditions, and achieve less reaction by-products, low requirements for production equipment, High conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

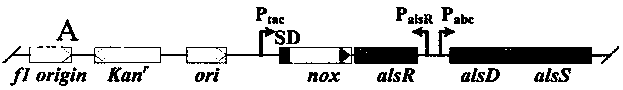

[0035] Embodiment 1: Construction of Escherichia coli engineering bacteria E.coli BL15

[0036] 1. Gene synthesis

[0037] Refer to the acetoin anabolic operon alsRSD (NCBI gene number: A3UG_05855, A3UG_05860, A3UG_05865) derived from Enterobacter cloacae subsp.dissolvens SDM published by NCBI, the NADH oxidase gene nox (NCBI gene number: AF536177.1) and P tac The sequence of the promoter (NCBI number: X15234.1), and the corresponding double-stranded DNA is artificially synthesized. Endonuclease cutting sites BglII and XhoI were added to the 5' end and 3' end of alsRSD respectively, and endonuclease cutting site BglII was added to the 3' end of gene nox.

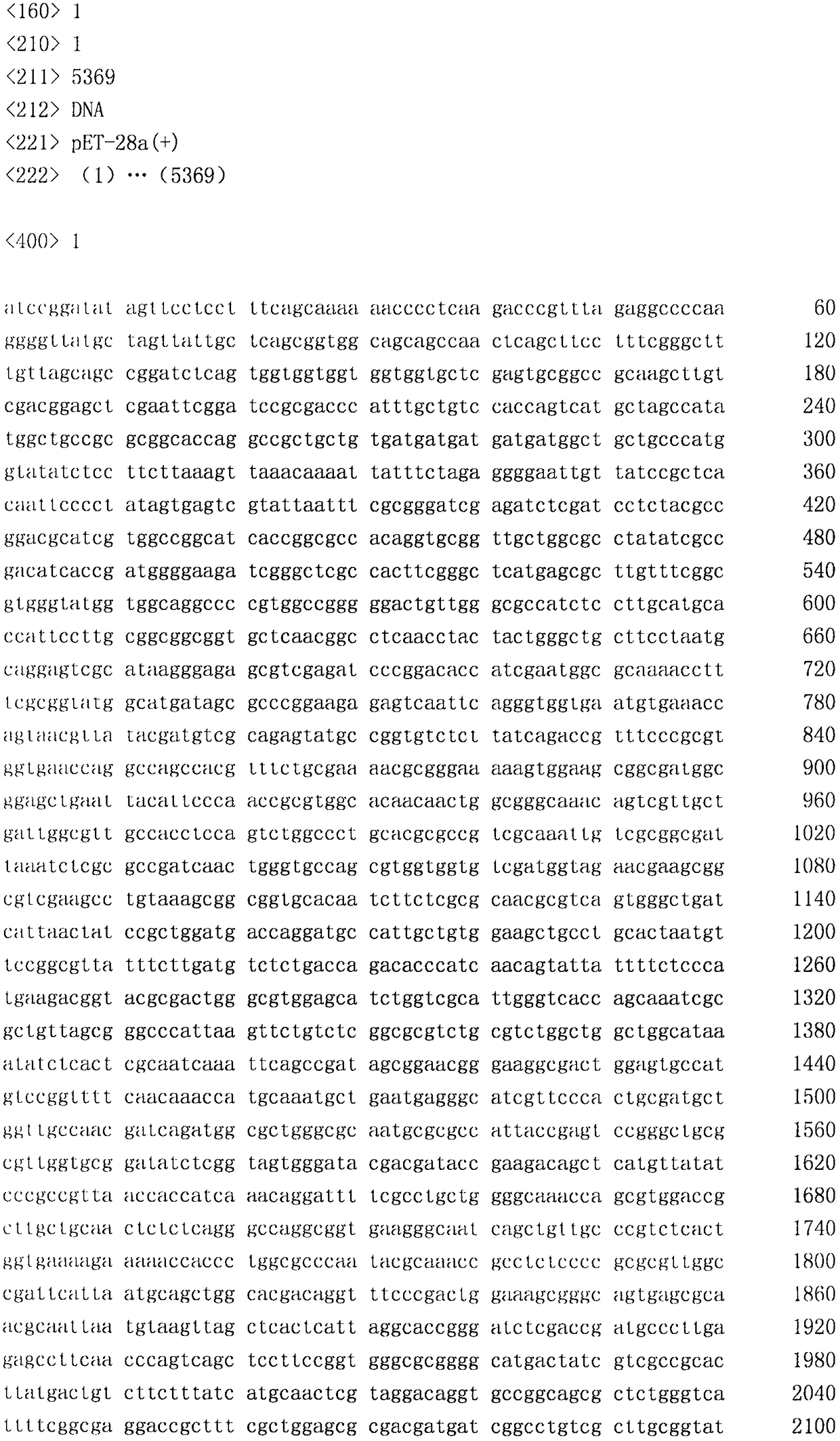

[0038] 2. The acetoin synthetic metabolic operon alsRSD was inserted into the plasmid pET-28a(+)

[0039] The artificially synthesized operon alsRSD was digested by BglII and XhoI, and the pET-28a(+) expression plasmid was treated by BglII and XhoI double digestion, the gel was cut and recovered, and then the expression p...

Embodiment 2

[0042] Embodiment 2: prepare the nutrient solution of Escherichia coli engineering bacteria E.coli BL15

[0043] 1. Plate culture: Aseptically streak the E. coli engineering bacteria E.coli BL15 onto the agar plate (LB medium contains 1.5-2.0% agar and 50mg / L kanamycin sulfate), in a constant temperature incubator at 37 ± 1 Incubate at ℃ for 12±2 hours;

[0044] 2. Seed culture: Aseptic operation, use a sterile toothpick to pick up a single colony from step (1), inoculate into LB liquid medium containing 50 mg / L kanamycin sulfate, and culture on a constant temperature shaker at 37±1°C with shaking After 12±2 hours, the activated bacterial liquid of Escherichia coli engineering bacteria E.coli BL15 was obtained;

[0045] Wherein, the formula of the LB medium described in the above steps (1) and (2) is: 1L of distilled water contains: 5g of yeast powder, 10g of peptone, 10g of sodium chloride, and sterilized at 121°C for 20min.

Embodiment 3

[0046] Embodiment 3: Escherichia coli engineering bacteria E.coli BL15 ferments glucose to produce acetoin

[0047] Under sterile conditions, activate Escherichia coli engineering bacteria E.coli BL15, and inoculate the activated bacterial solution into the fermentation medium with an inoculation volume of 5%-10% by volume. The temperature is 37±1°C, the stirring speed is 200-500rpm, and the sterile air intake is 0.5vvm-2.0vvm, and the fermentation is carried out for 48-96 hours. During the cultivation process, when the glucose concentration in the culture medium drops below 20g / L, add sterile 600-800g / L glucose solution until the glucose concentration in the culture medium is 40-60g / L. When the alcohol concentration no longer increases, stop the fermentation.

[0048] Wherein, the formula of the above-mentioned fermentation medium is: 1L distilled water contains 80g glucose, 10g yeast powder, 3.0gCH 3 COONa·3H 2 O, 0.60g KH 2 PO 4 , 0.40g MgSO 4 , 0.10g MnSO 4 , 0.060g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com