Bacterial agent treatment process for livestock breeding sewage

A treatment process, livestock and poultry breeding technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, special compound water treatment, etc., can solve environmental secondary pollution, waste water not up to the treatment standard, bacteria species The ability to deal with waste water is low, etc., to achieve the effect of long service life, good mechanical bulk, and rough fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

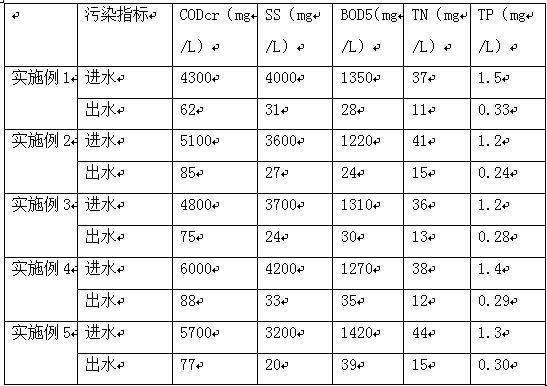

Examples

Embodiment 1

[0028] (1) Cultivation of anaerobic bacteria and aerobic bacteria: Preparation of medium: 0.5% lactose, 0.8% sodium hydrogen selenite, 0.5% disodium hydrogen phosphate, 0.4% L-cystine, 1% peptone, phosphoric acid Potassium dihydrogen is 0.7%, and the rest is water. Adjust the pH value to 7. After sterilizing at 120°C for 21 minutes, medium A, B, and C are obtained; Methanococcus, Lactobacillus to medium A, inoculate Thiobacillus thiaphus, Thiobacillus ferrooxidans, Acinetobacter junii, Clostridium amylosporans, yeast in a sterile room at a ratio of 1.5:0.5:2:3:5 Bacteria to medium B, culture temperature 30°C, culture time 45 hours;

[0029] (2) Strain domestication and intensive cultivation: 30% of the sludge obtained from the secondary sedimentation tank of the sewage treatment plant, 0.5% of sodium biselenite, and 0.5% of lactose were put into the aerobic strain pool and the anaerobic strain pool respectively. , 0.5% potassium dihydrogen phosphate, 0.5% multivitamin, 2% sodiu...

Embodiment 2

[0036] (1) Cultivation of anaerobic bacteria and aerobic bacteria: Preparation of medium: 0.5% lactose, 0.4% sodium hydrogen selenite, 0.3% disodium hydrogen phosphate, 0.5% L-cystine, 1% peptone, phosphoric acid Potassium dihydrogen is 0.8%, and the rest is water. Adjust the pH value to 7. After sterilizing at 125°C for 23 minutes, medium A, B, and C are obtained; Methanococcus, Lactobacillus to medium A, inoculate Thiobacillus thiooxidans, Thiobacillus denitrificans, denitrifying phosphorus accumulating bacteria, Bacteroides succinic acid, and yeast to culture in a sterile room according to 1:1:2:3:5 Base B, culture temperature 28°C, culture time 35 hours;

[0037] (2) Strain domestication and intensive cultivation: 20% of the sludge obtained from the secondary sedimentation tank of the sewage treatment plant, 0.5% of sodium biselenite, and 0.5% of lactose were put into the aerobic strain pool and the anaerobic strain pool respectively. , 0.5% potassium dihydrogen phosphate...

Embodiment 3

[0044] (1) Cultivation of anaerobic bacteria and aerobic bacteria: Preparation of medium: 0.4% lactose, 0.6% sodium hydrogen selenite, 0.7% disodium hydrogen phosphate, 0.3% L-cystine, 1% peptone, phosphoric acid Potassium dihydrogen is 0.4%, and the rest is water. Adjust the pH value to 7.5. After high-temperature sterilization at 115°C for 25 minutes, medium A, B, and C are obtained; Methanococcus, Lactobacillus to medium A, inoculate Thiobacillus denitrifica, Rhodocyclobacterium crimson, Bacillus cereus, yeast to medium B in the proportion of 2:2:3:5 in the sterile room, culture temperature 25°C, incubation time 40 hours;

[0045] (2) Strain domestication and intensive cultivation: 28% of sludge obtained from the secondary sedimentation tank of the sewage treatment plant, 0.5% of sodium biselenite, and 0.5% of lactose were put into the aerobic strain pool and anaerobic strain pool respectively. , 0.5% potassium dihydrogen phosphate, 1% multivitamin, 2% sodium gluconate, 1%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com