Coordination polymer reinforced basalt fiber composite material and preparation method thereof

A technology of basalt fiber and coordination polymer, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of substandard treatment, poor adsorption effect of heavy metal pollutants, etc., and achieves a simple and excellent preparation method. Handles the effect of high adsorption performance and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

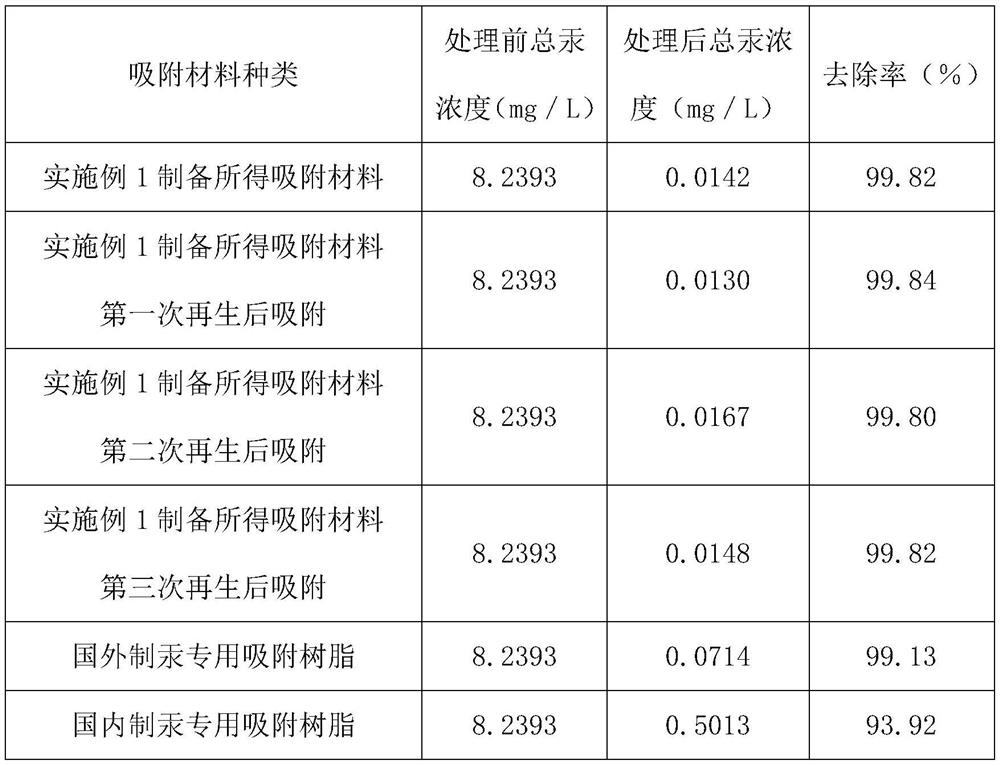

Embodiment 1

[0026] Add 70 parts by weight of pure natural basalt fiber and 16 parts by weight of mercapto-containing silane coupling agent to absolute ethanol, and uniformly disperse through high-speed mechanical stirring. The stirring time is 1 hour and the stirring speed is 1000rpm. Mixture A. Mix 40 parts by weight of cyclohexane ethylenediamine tetraacetic acid series organic ligands for synthesizing the coordination polymer with N,N-dimethylformamide (DMF) solvent to obtain an organic ligand solution. Then, the obtained organic ligand solution was added into the mixed solution A, and mixed evenly, the stirring time was 30 minutes, and the stirring speed was 1000 rpm, and the mixed solution B was obtained. Mix 60 parts by weight of calcium sulfide synthesized as a coordination polymer with N,N-dimethylformamide (DMF) solvent to obtain a metal ion solution. Then the obtained metal ion solution was added into the mixed solution B, and mixed uniformly, the stirring time was 30 minutes, ...

Embodiment 2

[0031]Add 80 parts by weight of pure natural basalt fiber and 10 parts by weight of mercapto-containing silane coupling agent to absolute ethanol, and uniformly disperse them by means of high-speed mechanical stirring. The stirring time is 2 hours and the stirring speed is 800rpm. Mixture A. Mix 60 parts by weight of the iminodiacetic acid series organic ligands of the synthetic coordination polymer with N,N-dimethylformamide (DMF) solvent to obtain an organic ligand solution. Then, the obtained organic ligand solution was added into the mixed solution A, and mixed uniformly, the stirring time was 60 minutes, and the stirring speed was 800 rpm, and the mixed solution B was obtained. Mix 50 parts by weight of calcium chloride for synthesizing the coordination polymer with N,N-dimethylformamide (DMF) solvent to obtain a metal ion solution. Then the obtained metal ion solution was added into the mixed solution B, and mixed uniformly, the stirring time was 60 minutes, and the sti...

Embodiment 3

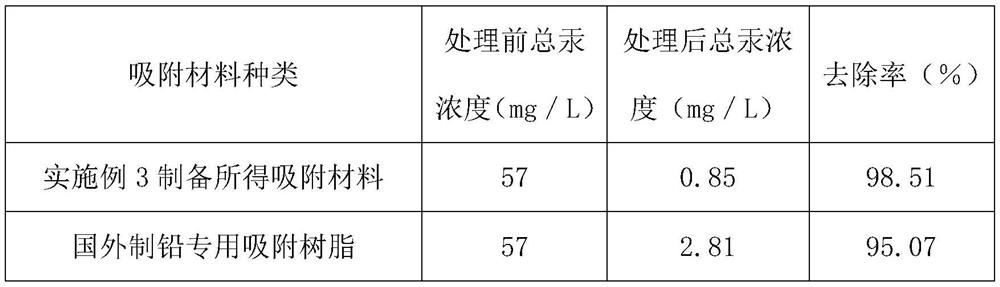

[0036] Add 60 parts by weight of pure natural basalt fiber and 5 parts by weight of mercapto-containing silane coupling agent into absolute ethanol, and uniformly disperse through high-speed mechanical stirring. The stirring time is 1.5 hours, and the stirring speed is 600rpm. Mixture A. Mix 70 parts by weight of anthranilic acid organic ligands synthesized in the coordination polymer with N,N-dimethylformamide (DMF) solvent to obtain an organic ligand solution. Then, the obtained organic ligand solution was added into the mixed solution A, and mixed uniformly, the stirring time was 90 minutes, and the stirring speed was 600 rpm, and the mixed solution B was obtained. Mix 70 parts by weight of calcium nitrate for synthesizing the coordination polymer with N,N-dimethylformamide (DMF) solvent to obtain a metal ion solution. Then the obtained metal ion solution was added into the mixed solution B, and mixed uniformly, the stirring time was 90 minutes, and the stirring speed was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com