Preparation method for cast soluble magnesium alloy composite fracturing ball surface protection layer

A technology of composite materials and fracturing balls, which is applied in the direction of surface reaction electrolytic coatings, devices for coating liquid on the surface, coatings, etc., can solve the problem that the protective effect of fracturing balls needs to be improved, and the protection methods and process parameters are rarely reported. , affect the surface quality of micro-arc oxidation ceramic coatings, etc., to achieve good protection, compact structure, and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

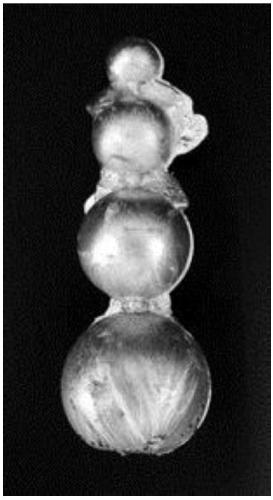

[0028] The floating beads / magnesium alloy composite material soluble fracturing balls in this embodiment include the following composition by weight percentage: 6% floating beads, 15% Al, 3% Zn, 0.5% Cu, 1% Ni, and the balance is Mg . The raw materials used are 100-150 mesh floating beads (see Table 1 for components), AZ91D magnesium alloy ingot, industrial pure aluminum plate (99.5wt.%), pure zinc powder (95.0wt.%), pure nickel powder (99.5wt.%) %), pure copper powder (99.7wt.%). The particle size of raw materials is: zinc powder 20μm-50μm, copper powder 20μm-40μm, nickel powder 20μm-50μm.

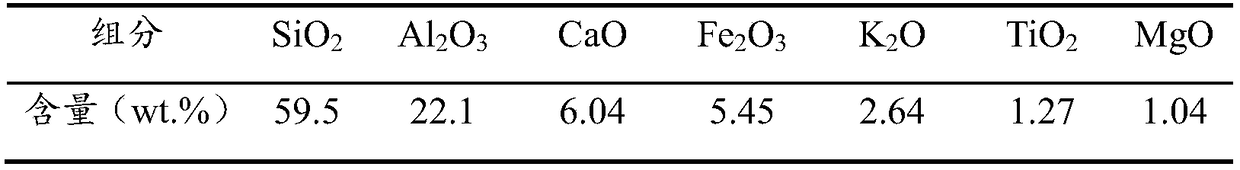

[0029] Table 1 components of floating beads

[0030]

[0031] The specific preparation process is as follows: firstly, 100-150 mesh floating beads are screened out with a sampling sieve, and then alkali washing is carried out to remove impurities on the surface of the floating beads. The alkali washing step is: prepare a sodium hydroxide aqueous solution with a concentration of 1.5m...

Embodiment 2

[0036] The difference between this example and Example 1 is that the inventive float / magnesium alloy composite soluble fracturing ball comprises the following composition by weight percentage: 8% float, 15% Al, 3% Zn, 0.5% Cu, 1% Ni, the balance is Mg.

[0037] When the cutting process parameters are cutting depth of 2.0mm, cutting speed of 35m / min, and feed rate of 0.05mm / r, the surface roughness is relatively low, and the Ra value is 0.33μm.

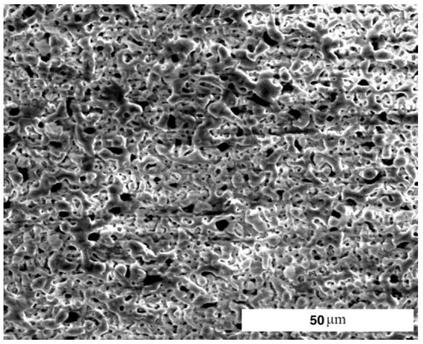

[0038] The concentration of the micro-arc oxidation electrolyte used is 8g / L Na 2 SiO 3 and 2g / L KOH, when the micro-arc oxidation process parameter is the current density 35A / dm 2 When the pulse frequency is 25Hz, the duty ratio is 50%, and the oxidation time is 40min, the roughness Ra of the ceramic coating obtained on the surface of the floating beads / magnesium alloy soluble fracturing ball is 1.4μm, and the anti-corrosion performance is good, which meets the production requirements.

Embodiment 3

[0040] The difference between this example and Example 1 is that the inventive soluble floating beads / magnesium alloy composite fracturing ball comprises the following composition by weight percentage: 6% floating beads, 12% Al, 3% Zn, 0.5% Cu, 1% Ni, the balance is Mg.

[0041] When the cutting process parameters are cutting depth of 1.5mm, cutting speed of 45m / min, and feed rate of 0.05mm / r, the surface roughness is relatively low, and the Ra value is 0.48μm.

[0042] The concentration of the micro-arc oxidation electrolyte used is 6g / L Na 2 SiO 3 and 3g / L KOH, when the micro-arc oxidation process parameter is the current density 40A / dm 2 When the pulse frequency is 55Hz, the duty ratio is 50%, and the oxidation time is 50min, the roughness Ra of the ceramic coating obtained on the surface of the floating beads / magnesium alloy soluble fracturing ball is 1.3μm, and the anti-corrosion performance is good, which meets the production requirements.

[0043] Using the mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com