A kind of fabric stiffening agent and preparation method thereof

A technology for stiffening agent and fabric, applied in the field of fabric stiffening agent and its preparation, can solve the problem of little dependence on equipment, and achieve the effects of less dependence on equipment, excellent performance stability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

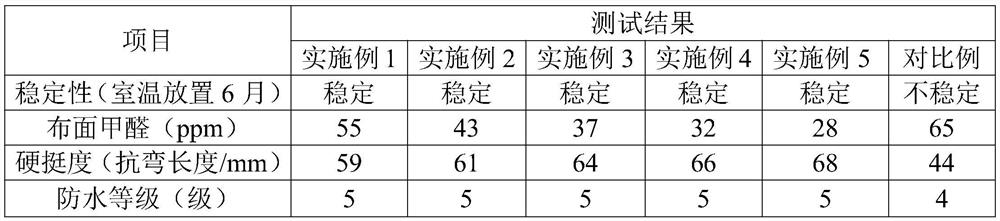

Examples

Embodiment 1

[0024] A preparation method of a fabric stiffening agent, comprising the steps of:

[0025] 1. Dissolve 20g of (2-acryloyloxyethyl)trimethylammonium chloride and 10g of sodium alginate in 50g of tetrahydrofuran, stir and react at room temperature for 10 hours, then remove tetrahydrofuran by rotary evaporation, and then add dichloromethane Extract the product, and finally filter and remove dichloromethane by rotary evaporation to obtain (2-acryloyloxyethyl) quaternary ammonium alginate;

[0026] Ⅱ. Add 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine- 2,4,6(1H,3H,5H)-triketone 10g, allyl cyclodextrin 20g, isobutyl methacrylate 10g, (2-acryloyloxyethyl) quaternary ammonium alginate 10g, Potassium persulfate 0.5g, fatty alcohol polyoxyethylene ether 0.5g and water 150g were stirred and reacted for 2 hours under a nitrogen atmosphere at 65°C, and then dimethyloldihydroxyethylene urea was added to it. 6.3g and sodium carbonate 3g were added in Stir and react at 75°C for 6 ho...

Embodiment 2

[0029] A preparation method of a fabric stiffening agent, comprising the steps of:

[0030] 1. Dissolve 25g of (2-acryloyloxyethyl)trimethylammonium chloride and 10g of sodium alginate in 65g of tetrahydrofuran, stir and react at room temperature for 10.5 hours, then remove tetrahydrofuran by rotary evaporation, and then add dichloromethane Extract the product, and finally filter and remove dichloromethane by rotary evaporation to obtain (2-acryloyloxyethyl) quaternary ammonium alginate;

[0031] Ⅱ. Add 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine- 2,4,6(1H,3H,5H)-triketone 10g, allyl cyclodextrin 20g, isobutyl methacrylate 10g, (2-acryloyloxyethyl) quaternary ammonium alginate 10g, Sodium persulfate 0.6g, isomeric alcohol polyoxyethylene ether 0.6g and water 165g, stirred and reacted for 2.5 hours under a helium atmosphere at 68°C, and then added dimethyloldihydroxyethylene urea 6.3g and sodium bicarbonate 3g, stirred and reacted at 79°C for 7 hours, cooled to room...

Embodiment 3

[0034] A preparation method of a fabric stiffening agent, comprising the steps of:

[0035] 1. Dissolve 30g of (2-acryloyloxyethyl)trimethylammonium chloride and 10g of sodium alginate in 75g of tetrahydrofuran, stir and react at room temperature for 11 hours, then remove tetrahydrofuran by rotary evaporation, and then add dichloromethane Extract the product, and finally filter and remove dichloromethane by rotary evaporation to obtain (2-acryloyloxyethyl) quaternary ammonium alginate;

[0036] Ⅱ. Add 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine- 2,4,6(1H,3H,5H)-triketone 10g, allyl cyclodextrin 20g, isobutyl methacrylate 10g, (2-acryloyloxyethyl) quaternary ammonium alginate 10g, Ammonium persulfate 0.7g, castor oil polyoxyethylene ether 0.7g and water 180g were stirred and reacted for 2.7 hours at 70°C in a neon atmosphere, and then dimethyloldihydroxyethylene urea 6.3g and ammoniacal liquor 3g were added thereto. Stir and react at 80°C for 7.2 hours, cool to room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com