Porous spherical core-shell structure silicon-carbon composite material and preparation method thereof and lithium ion battery

A silicon-carbon composite material, porous spherical technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as low charging and discharging efficiency, consumption of electrolyte, silicon active material and current collector shedding, etc. The effect of packing and tapping density, improving volume energy density, and novel morphology and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

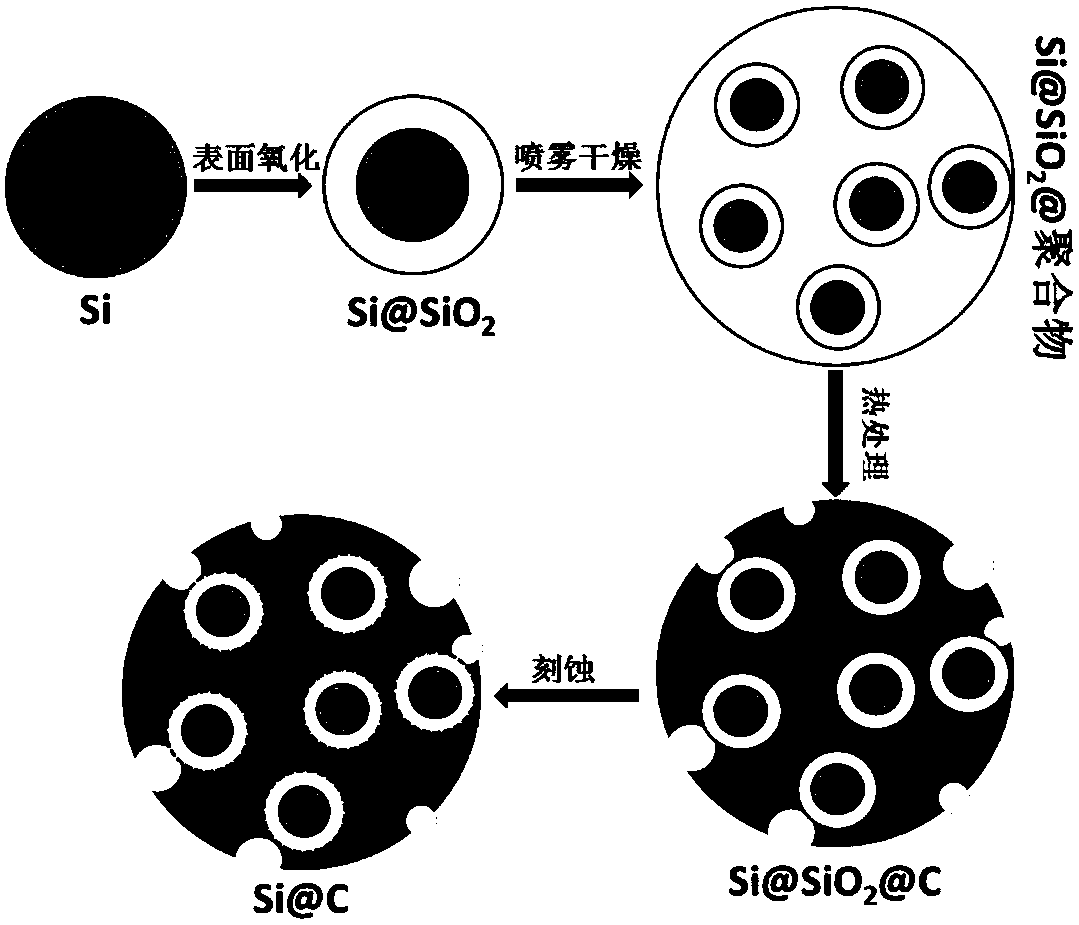

[0045] Such as figure 1 As shown, the preparation method of the silicon-carbon composite material in this embodiment, the steps are as follows:

[0046] S1. Prepare raw materials, take 50g of 100nm nano-silicon powder, and heat it at 400°C for 3 hours in an air atmosphere to obtain Si / SiO with the surface layer oxidized 2 Nanoparticles were added to 100 g of N,N-dimethylformamide (DMF) solution and 0.05 g of sodium dodecylbenzenesulfonate was added for ultrasonic dispersion to obtain a mixed solution 1.

[0047] S2. Add 200g polyacrylonitrile (PAN) to 500g N,N-dimethylformamide (DMF) solution, heat and dissolve at 70°C until it becomes a homogeneous liquid, then add 50g polymethyl methacrylate (PMMA), continue to stir and use Heating with residual heat until completely dissolved to obtain mixed solution 2;

[0048] The mass ratio of nano silicon powder: organic dispersant: polymer 1: polymer 2: solvent is 1:0.001:4:1:12;

[0049] S3. Add the mixed solution 1 of step S1 into...

Embodiment 2

[0052] The preparation method of the silicon-carbon composite material of this embodiment, its steps are as follows:

[0053] S1. Take 40g of 800nm nano-silicon powder and heat it at 600°C for 1h in an air atmosphere to obtain Si / SiO whose surface layer is oxidized 2 Nanoparticles were added to 100 g of tetrahydrofuran solution and 0.05 g of triethylhexyl phosphoric acid was added for ultrasonic dispersion to obtain mixed solution 1.

[0054] S2. Add 200 g of polyvinylidene fluoride to 500 g of tetrahydrofuran solution, heat and dissolve at 100° C. to a homogeneous liquid, then add 30 g of polyethylene glycol, continue stirring and use residual heat to heat until completely dissolved, and obtain mixed solution 2;

[0055] Nano silicon powder: organic dispersant: polymer 1: polymer 2: the mass percentage of solvent is 1: 0.00125: 4: 0.75: 15;

[0056] S3. Add the mixed solution 1 of step S1 into the mixed solution 2 obtained in step S2, fully stir and disperse to obtain the ...

Embodiment 3

[0059] The preparation method of the silicon-carbon composite material of this embodiment, its steps are as follows:

[0060] S1. Take 60g of 20nm nano-silicon powder and heat it at 350°C for 10h in an air atmosphere to obtain Si / SiO whose surface layer is oxidized 2 Nanoparticles were added to 100 g of dimethyl sulfoxide solution and 0.09 g of sodium dodecylbenzenesulfonate was added for ultrasonic dispersion to obtain a mixed solution 1.

[0061] S2. Add 300g of polyamide to 500g of dimethyl sulfoxide solution, heat and dissolve at 60°C until it becomes a homogeneous liquid, then add 60g of ethylene-vinyl acetate copolymer, continue to stir and heat until completely dissolved with residual heat, and obtain mixed solution 2;

[0062] Nano silicon powder: organic dispersant: polymer 1: polymer 2: the mass percentage of solvent is 1:0.0015:5:1:10;

[0063] S3. Add the mixed solution 1 of step S1 into the mixed solution 2 obtained in step S2, fully stir and disperse to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com