Preparation method of drug-loadable gelatin embolization microspheres

A technology of gelatin and microspheres, which is applied in medical science, application, surgery, etc. It can solve the problem of the inability of smaller and larger size microspheres, the uncertain time of in vivo degradation of blood vessel recanalization, and the difficulty of uniform particle size of microspheres. In order to achieve the effects of shortening the degradation time range, improving the embolization efficiency, and improving the success rate of embolization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Prepare a gelatin solution, dissolve the gelatin in water for injection to prepare 900ml of a gelatin solution with a mass fraction of 20%, heat and stir in a water bath at 50°C for 1.0h until uniformly dissolved. After dissolving, sonicate for 30 minutes to remove the air bubbles in the solution, seal it and place it in a water bath at 50°C to keep warm for later use;

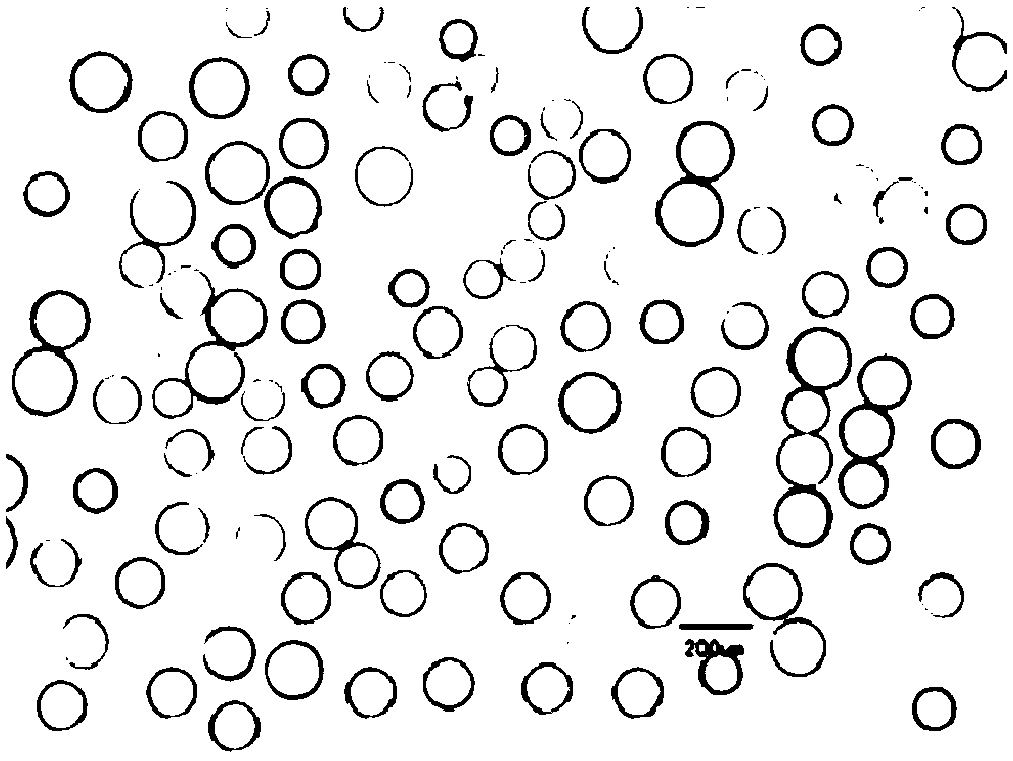

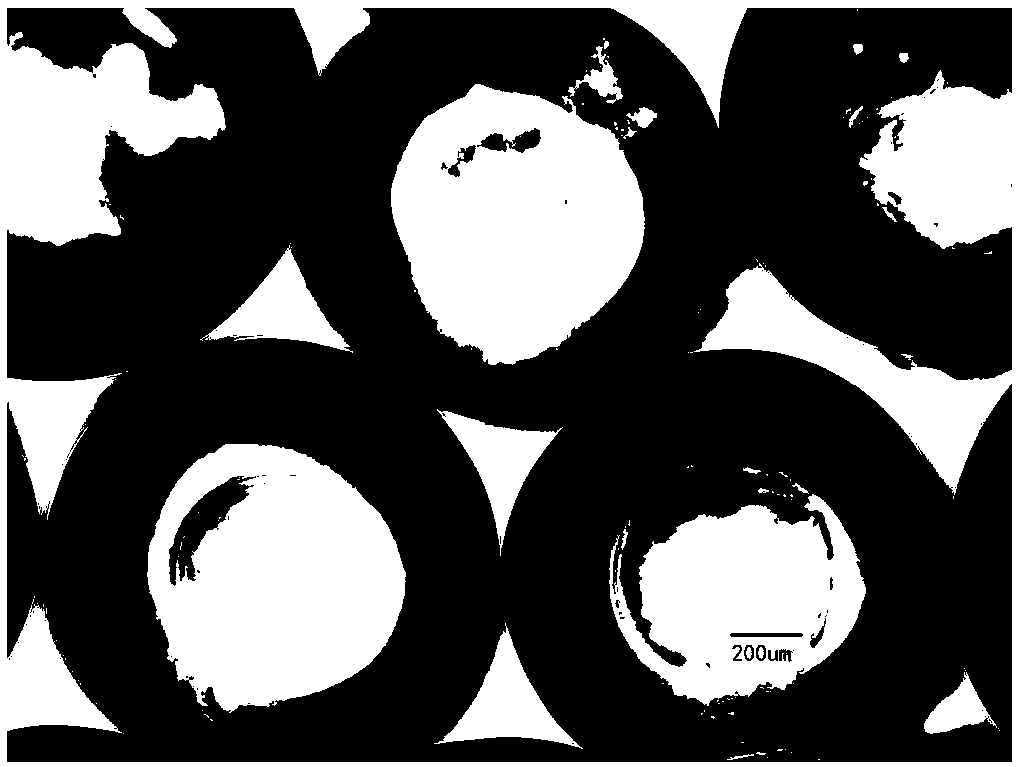

[0041](2) To synthesize gelatin microspheres, measure 3000ml of liquid paraffin and pour it into the reaction kettle, set the reaction temperature to 50°C, set the stirring speed to 300-500rpm, use a peristaltic pump dripping device, select the needle size as 20G, and put the step (1 ) was added dropwise to liquid paraffin at a flow rate of 10ml / min. After the dropwise addition, the temperature of the reaction system was lowered to 10-12°C, and 0.1mol / l sodium hydroxide solution was added to adjust the pH value of the system to 8.0-8.5 160ml of formaldehyde solution with a mass percentage concentrat...

Embodiment 2

[0049] (1) Prepare gelatin solution, dissolve gelatin in water for injection, prepare 900ml of gelatin solution with a mass fraction of 15%, heat and stir in a water bath at 60°C for 1.0h until it dissolves evenly, and remove it from the solution with ultrasound for 30min after dissolution bubbles, seal and place in a 60°C water bath to keep warm for later use;

[0050] (2) To synthesize gelatin microspheres, measure 5000ml of liquid paraffin and pour it into a reaction kettle, set the reaction temperature to 60°C, and set the stirring speed to 700-1000rpm. Use the microfluidic chip device to drop the gelatin solution in step (1), select the inner diameter of the chip pipe outlet as 50 μm, control the flow rate of the gelatin solution to 5ml / min, reduce the temperature of the reaction system to 5°C after the addition is completed, and add 0.1mol / 1 potassium hydroxide solution to adjust the pH value of the system to 8.5-9.0, and use a constant pressure titration funnel to add ...

Embodiment 3

[0058] (1) Prepare gelatin solution, dissolve gelatin in water for injection, prepare 900ml of gelatin solution with a mass fraction of 10%, and heat and stir in a water bath at 60°C for 1.0h until it dissolves evenly. After dissolving, use ultrasound for 30min to remove it from the solution bubbles, seal and place in a 60°C water bath to keep warm for later use;

[0059] (2) To synthesize gelatin microspheres, measure 3000ml of ethyl acetate and pour it into the reaction kettle, set the reaction temperature to 50°C, set the stirring speed to 100-300rpm, use a peristaltic pump to drop gelatin device, select the needle size as 20G, and put the step (1) The gelatin solution in (1) is added dropwise in the described ethyl acetate with the flow rate of 15ml / min, after dropping is finished, reduce reaction system temperature and be 10 ℃, add the sodium hydroxide solution of 1mol / l to adjust system pH value to 8.0 to 9.0, use a constant pressure titration funnel to add 200ml of form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com