Thermally-stable emulsion of antigen as well as preparation method and application of thermally-stable emulsion

A heat-stable, antigen-based technology, applied in emulsion delivery, pharmaceutical formulations, antibody medical components, etc., can solve the problems of long antigen release time, expensive equipment, complicated operation steps, etc., to achieve good safety and stability, reduce Transport and storage costs, effects of good antigen thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] In this example, the biomimetic mineralization of aluminum hydroxide particles was used to prepare the heat-stable emulsion of antigen

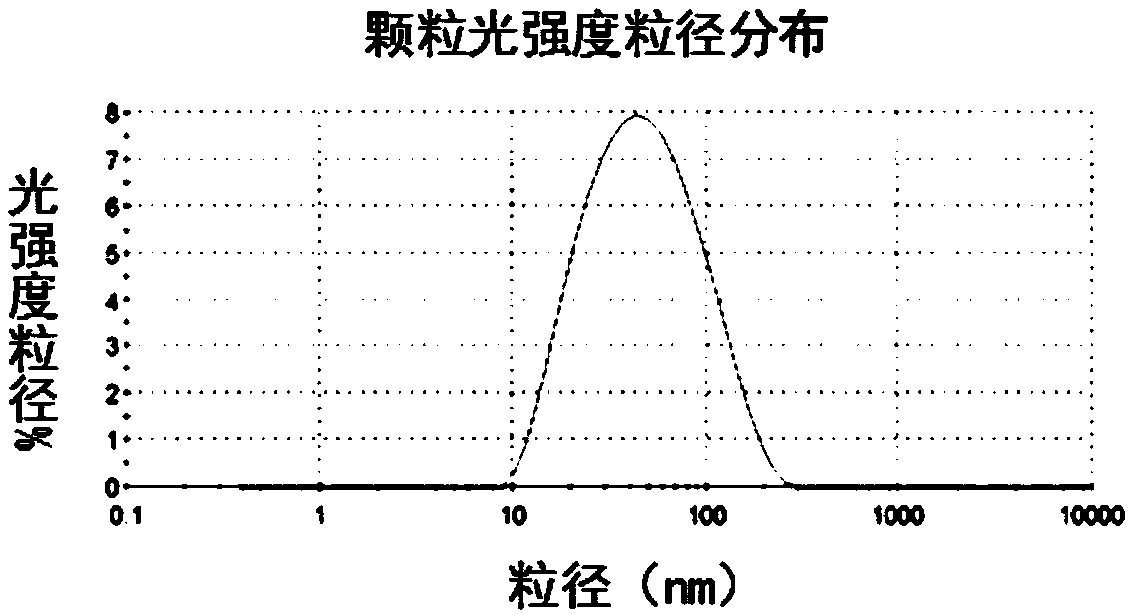

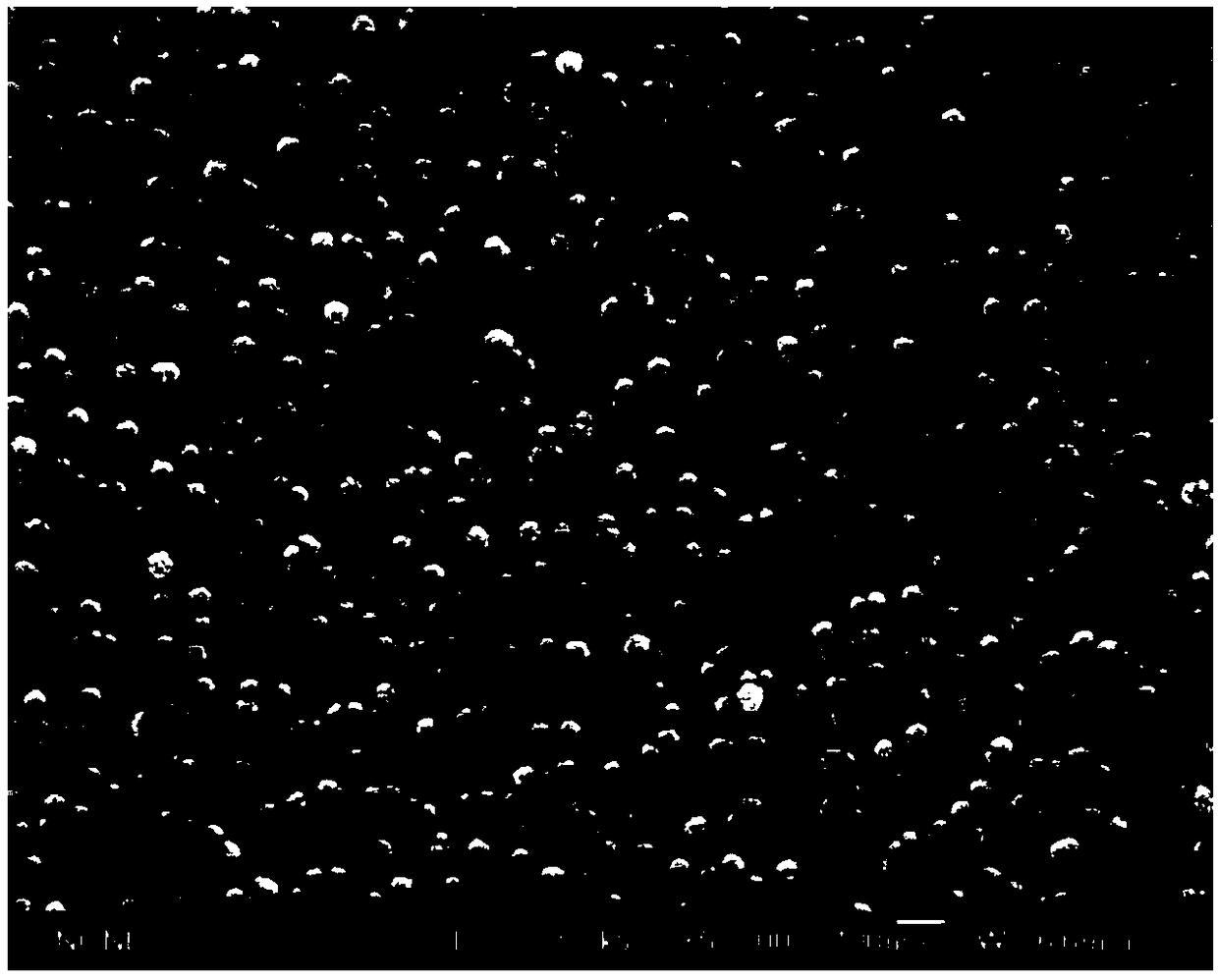

[0093] (1) Preparation of aluminum hydroxide particles by alkoxide hydrolysis-hydrothermal method: weigh a certain amount of deionized water with a measuring cylinder and place it in a 100mL three-neck flask, heat to 85°C, and then add aluminum isopropoxide powder. Aluminum isopropoxide and deionized water were mixed at a molar ratio of 1:100, stirred for 2 hours, and cooled to room temperature naturally. The above reaction solution is put into a stainless steel high-pressure container lined with polytetrafluoroethylene, and subjected to hydrothermal treatment at a certain temperature. After the hydrothermal reaction is completed, the material is naturally cooled, centrifuged to separate the solid phase product, washed with deionized water three times, and vacuum-dried to obtain aluminum hydroxide particles. Aluminum hydroxide particl...

Embodiment 2

[0101] In this example, the biomimetic mineralization of calcium phosphate particles was used to prepare an antigen heat-stable emulsion

[0102] (1) Preparation of hollow calcium phosphate particles by template method:

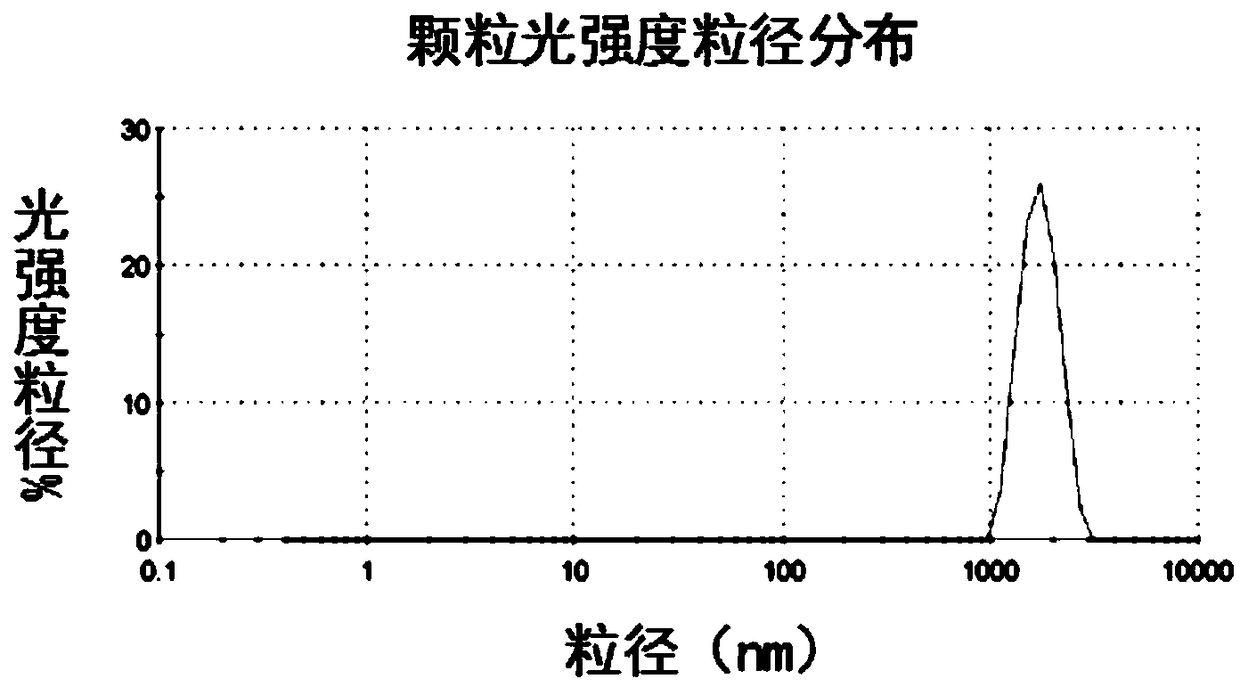

[0103] After mixing 3.0g Tween 80, 0.25g PEG 6000, 3.0mL 0.5mol / L Tris-HCl (pH8.0) and 1.5mL deionized water and stirring evenly, ultrasonic 20min to form non-ionic surfactant vesicles, drop into 3.55mL CaCl 2 (0.175mol / L) solution, after stirring for 0.5h, add 3.55mL Na 2 HPO 4 (0.175mol / L) solution can obtain the suspension of sodium phosphate particle, add 0.83mL MgCl 2 solution (0.075mmol / L) to stabilize the newly formed calcium phosphate particles, continue to stir for 2h, centrifuge and wash, and vacuum dry to obtain hollow calcium phosphate particles. The average particle size of the particles is 210nm, the shell thickness is 30-40nm, and the PDI value of the particles is 0.289. The prepared particles are hollow spheres.

[0104] (2) Biomimetic m...

Embodiment 3

[0109] In this example, peanut-like calcium carbonate particles were used to prepare the heat-stable antigen emulsion by biomimetic mineralization

[0110] (1) Prepare peanut-shaped calcium carbonate particles by liquid phase direct mixed precipitation method:

[0111] Weigh calcium acetate and trisodium citrate with an electronic balance and dissolve them in 200mL of distilled water (the mass concentration of trisodium citrate is 10wt.% and 30wt.% respectively), and add 10wt.% sodium carbonate aqueous solution (50mL ), stirred (300rpm) for 3h, filtered, washed the precipitate three times with distilled water and absolute ethanol, and dried at 70°C to obtain peanut-shaped calcium carbonate particles. The length of the particles is 7.2 μm, the ratio of the long axis to the short axis is 2:1, and the morphology of the prepared particles is peanut-like.

[0112] (2) Biomimetic mineralization of proteins:

[0113] Accurately weigh 3.1 g of calcium carbonate particles with an ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com