Preparation method and applications of black fungus composite small molecule peptide powder

A technology of small molecular peptides and black fungus, applied in the field of food industry, can solve the problems of high diet cost and insufficient effect of auxiliary treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] Example 1: Preparation of Black Fungus Polypeptide Dry Powder

[0122] 1. Take 100 kg of black fungus, select, wash, and crush in a mechanical roller. Add 5 times the weight of black fungus in distilled water at 55°C, and crush the black fungus tissue and homogenate for 2 hours in a high-pressure homogenizer.

[0123] 2. Use 6.0mol / L HCl solution to control the pH value to 5.5. According to the mass concentration of the substrate is 5%, according to the amount of Aspergillus oryzae exocutase 8%, the amount of papain solution 15%, under the constant temperature condition of 55 ℃, the amount of Aspergillus oryzae flavored enzyme is 5%, successively use exonuclease to act for 20 hours , papain acts for 60 hours, Aspergillus oryzae flavor enzyme acts for 10 hours.

[0124] 3. Cool to room temperature, centrifuge at 3000r / min for 5 minutes, inactivate the supernatant at 70°C for 50 minutes, and concentrate under reduced pressure to obtain a concentrated peptide solution; a...

Embodiment 2

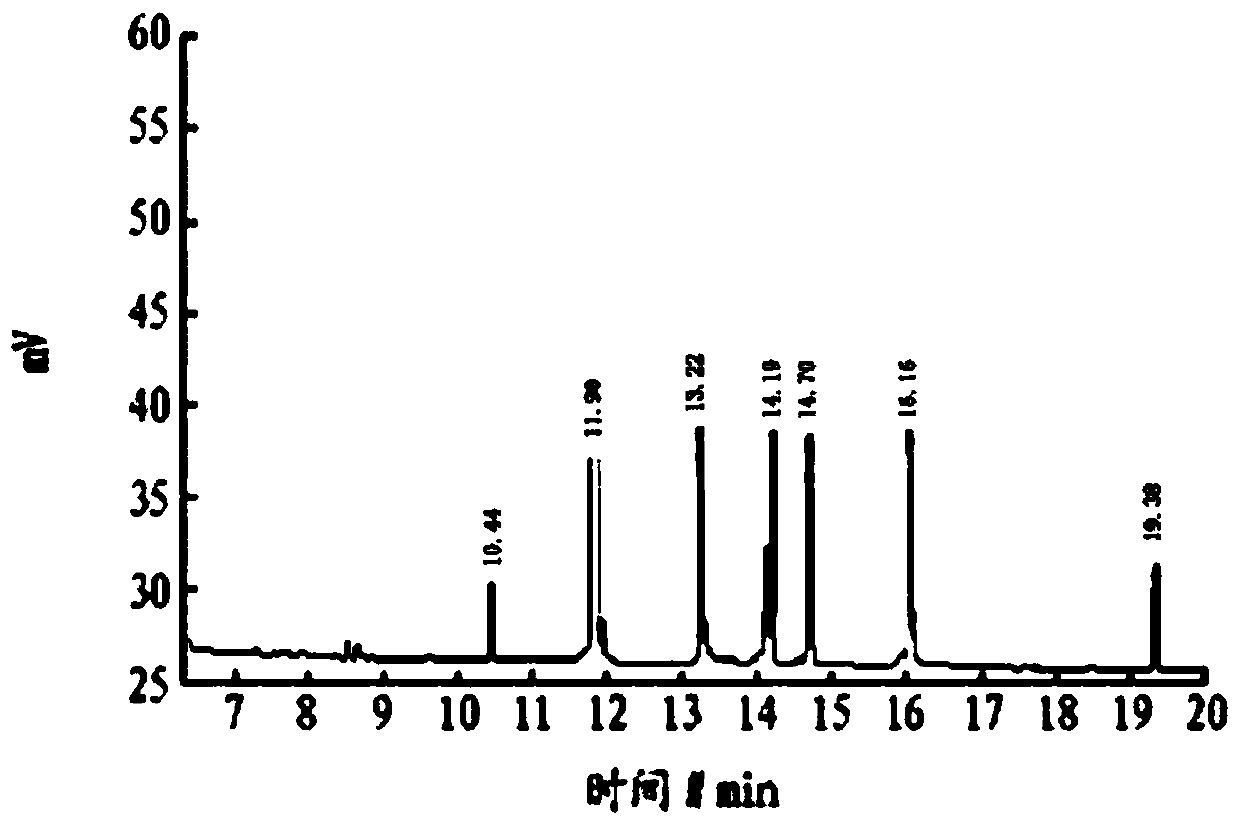

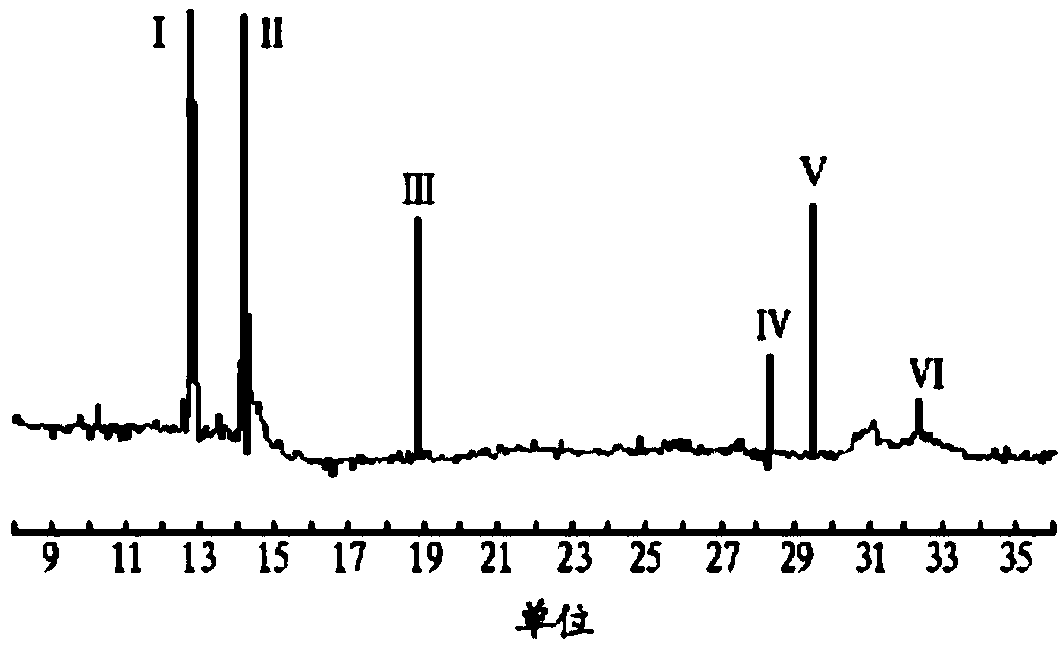

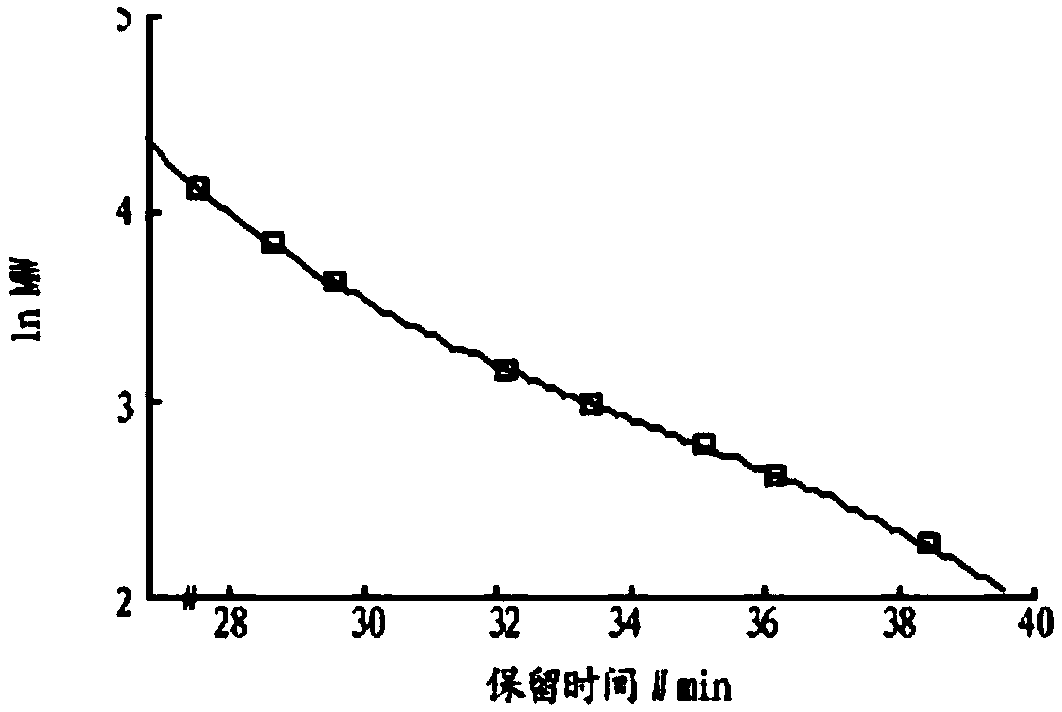

[0127] Example 2. Detection of black fungus polypeptides

[0128] 1 Materials and methods

[0129] 1.1 Raw materials and instruments The black fungus protein isolate homogenate in Example 1, protein content ≥ 89%; Neutral protease, Wuxi Genenco Bioengineering Co., Ltd., Xuemei brand (food grade); Alkaline protease, Wuxi Genen Ke Biological Engineering Co., Ltd., Xuemei brand (food grade); peptide molecular weight standard, Amersham Bio2sciences company, dedicated to capillary electrophoresis; microwave oven, LG Electronics Co., Ltd., MS22089T; formaldehyde, Xi’an Chemical Reagent Factory, analytically pure; high-efficiency capillary electrophoresis instrument , CE2212, manufactured by Peking University; gel permeation chromatography, 24142515, Waters, USA.

[0130] Detection method

[0131] 1. Formaldehyde titration method for detection of degree of hydrolysis and amino nitrogen (GB / T 14771-1993). The degree of hydrolysis is defined as the percentage of the peptide bond in ...

Embodiment 3

[0145] Example 3. Black fungus polypeptide is used to prepare granules

[0146] The concentrate obtained in step 3 was thoroughly mixed and spray-dried. 1. The black fungus small molecular active peptide dry powder obtained in Embodiment 1 is made into granules of certain specifications with a granulator, and is packed into required various quantitative packages with a vacuum packaging machine to make granules.

[0147] 5. Packaging of granules: 5g / bag, 20 bags / box.

[0148] Dosage and usage: Once in the morning and evening, take 1 bag each time, take it with warm water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com