Biological composite preservative, preparation method thereof and application thereof in sturgeon caviar

A composite fresh-keeping and biological method technology, applied in application, food science, food preservation, etc., can solve problems affecting the quality of caviar, achieve the effects of inhibiting bacterial reproduction, prolonging storage period, and extensive antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

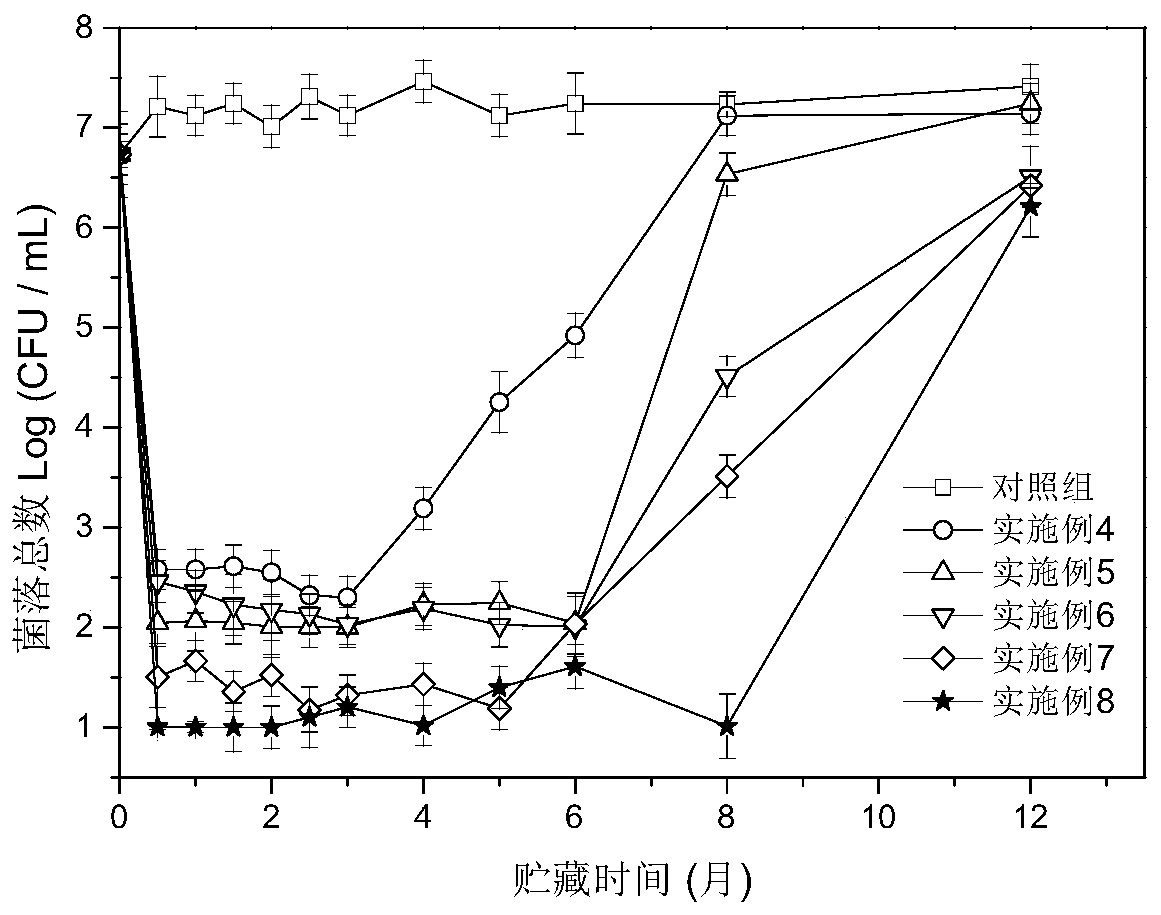

Image

Examples

Embodiment 1

[0034] The steps of preparing FAC6 by the enzymatic method are as follows:

[0035] Weigh 3.883.8g of ferulic acid, 3.065g of deep eutectic solvent, so that the molar mass ratio of ferulic acid and n-hexanol is 1:1.5, weigh 0.43g of Novozym 435 enzyme as an enzymatic reaction catalyst, and measure 50mL of tert-butanol As the reaction medium, put it in an oil bath at 70°C for 17h (react overnight), and use silica gel column chromatography, petroleum ether and ethyl acetate at a volume ratio of 4:1 as mobile phase for elution, and the prepared product is FAC6.

Embodiment 2

[0037] Described biological method prepares the step of bifidobacterium bacteriocin S as follows:

[0038] Bifidobacterium cultures grown in MRS-C broth for 28 h at 37 °C were heated to 80 °C for 30 min to kill cells and prevent bacteriocin degradation by inactivating proteolytic enzymes. After cooling to room temperature, the medium was adjusted to pH 8.0 with sterile 1 M NaOH and stirred overnight at 4 °C to facilitate the adsorption of bacteriocin molecules on the surface of the producer cells. Target cells were obtained by centrifugation, washed three times with 0.1 M PBS buffer, and then suspended in 0.1 mM NaCl (pH 3.0) to desorb bacteriocin molecules from producer cells. The cell suspension was stirred overnight at 4°C. The supernatant was dialyzed at 4°C for 24 h using a 1.0 kDa cut-off membrane to obtain Bifidobacterium bacteriocin S.

Embodiment 3

[0040] The extraction method step of described olive leaf extract is as follows:

[0041] Take by weighing choline chloride 1.24g, ethylene glycol 5.585g, make choline chloride and ethylene glycol molar mass ratio be 1:2, by heating choline chloride as different hydrogen bond donor (HBD) and hydrogen bond acceptor (HBA) to prepare a deep eutectic solvent. The mixture was placed in a water bath at 80° C. and stirred at 200 rpm until a uniform colorless liquid was obtained, which was the deep eutectic solvent. Mix 7.5mL of deep eutectic solvent and 2.5mL of ultrapure water in a closed container, put 2g of crushed olive leaves in the mixture, and place the closed container in a microwave extractor for extraction at 65°C for 20min. Get olive leaf extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com