Perovskite quantum dot ligand and preparation method and application thereof

A quantum dot and perovskite technology, applied in the field of semiconductor light-emitting materials, can solve the problems of destroying the crystal structure and luminescent properties of perovskite quantum dots, and achieve the effects of simple preparation method, improved stability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Correspondingly, the above-mentioned acrylate-based quaternary ammonium salt ligand is prepared by the following preparation method, which includes the following steps:

[0035] G01. Weigh and mix acrylate, haloalkane, and polymerization inhibitor to obtain the first mixture; wherein, the acrylate is R 1 OOCC 2 h 4 , the haloalkane is R 2 X, where R1 It is a short-chain hydrocarbon group with 2 to 4 carbon atoms, R 2 It is a long-chain hydrocarbon group with 8 to 18 carbon atoms, and X is a halogen atom; the first mixture is subjected to constant temperature heating and stirring reaction, and is cooled after 12 to 36 hours of reaction;

[0036] G02. Add anhydrous ether to wash the product obtained by the reaction, and collect the crude product; add acetone solution to the crude product to dissolve in saturation, cool and crystallize at a temperature of 0°C to 4°C, collect the crystals, and dry them to obtain Acrylate-based quaternary ammonium ligand.

[0037] Speci...

Embodiment 1

[0066] A green light-emitting perovskite quantum dot dispersion liquid coated with organic polymer.

[0067] The preparation method of the acrylate-based quaternary ammonium salt ligand is: add 50mmol (16.6695g) BODA and 50mmol (7.15g) DEA into a 100ml flask, then add 5wt% polymerization inhibitor phenothiazine, stir and heat at 50°C for 24h , after cooling, add anhydrous ether to wash 3 times to remove unreacted monomer, then saturate and dissolve it with acetone, put it in the refrigerator to cool and recrystallize, and dry it in a vacuum oven at 25°C for 24 hours to obtain a white solid powder, which is acrylate Ligands for quaternary ammonium ligands.

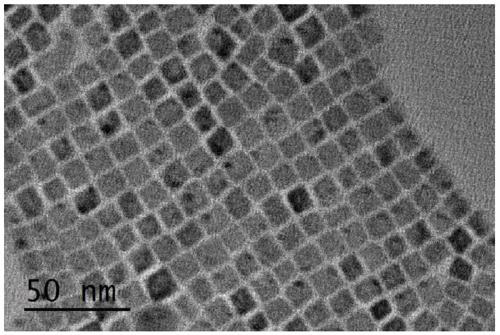

[0068] The preparation method of composite perovskite quantum dots coated with acrylate-based quaternary ammonium ligands on the surface is as follows: 0.07mmol CsBr, 0.1mmol PbBr2, 0,03mmol ligands are dissolved in 1ml dimethyl sulfoxide, dropwise into 20ml vigorous Add 1ml of acetonitrile, centrifuge at 10000rpm for 10mi...

Embodiment 2

[0070] A blue light-emitting perovskite quantum dot dispersion liquid coated with organic polymer.

[0071] The preparation method of the acrylate-based quaternary ammonium salt ligand is: add 50mmol (16.6695g) BODA and 50mmol (7.15g) DEA to a 100ml flask, then add 5wt% polymerization inhibitor phenothiazine, stir and heat at 50°C for 24h, After cooling, add anhydrous ether to wash 3 times to remove unreacted monomers, then saturate and dissolve them with acetone, put them in the refrigerator for cooling and recrystallization, and dry them in a vacuum oven at 25°C for 24 hours to obtain a white solid powder, which is a polymerizable Ligand.

[0072] The preparation method of composite perovskite quantum dots coated with acrylate-based quaternary ammonium ligands is as follows: 0.07mmol CsCl, 0.1mmol PbCl2, 0,03mmol ligands are dissolved in 1ml of dimethylformamide, dropwise into 20ml of vigorous In the stirred toluene, a blue-green precipitate is produced, then add 1ml of iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com