Ag/MnO2 catalyst, preparation method thereof, and application of same in removing formaldehyde at room temperature

A catalyst, Zhongyin technology, which is applied in the field of inorganic environmental protection catalytic materials, can solve the problems of low atomic utilization rate of active components, large size of metal particles, and difficulty in industrialization, and achieve the effect of simple and environmentally friendly preparation process, uniform size, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A Ag / MnO 2 The preparation method of catalyst comprises the following steps: (1) adding ammonium oxalate and silver precursor in potassium permanganate solution, after stirring and mixing uniformly, obtaining mixed solution; (2) carrying out water mixing solution in step (1) Thermal reaction, after the reaction is complete, the reaction product is suction filtered, washed, and dried to obtain a powder; (3) The powder in step (2) is subjected to a reduction reaction under a hydrogen atmosphere to obtain Ag / MnO 2 catalyst.

[0027] The solvent of the potassium permanganate solution in step (1) is not particularly limited, and can be a conventional choice of those skilled in the art, such as deionized water, C1-5 alcohols, C1-5 acetones, etc., preferably deionized water .

[0028] Preferably, the molar ratio of potassium permanganate to ammonium oxalate in step (1) is 1:2-2:1, more preferably 1:2.

[0029] Preferably, the mass ratio of silver in the silver precursor to ...

Embodiment 1

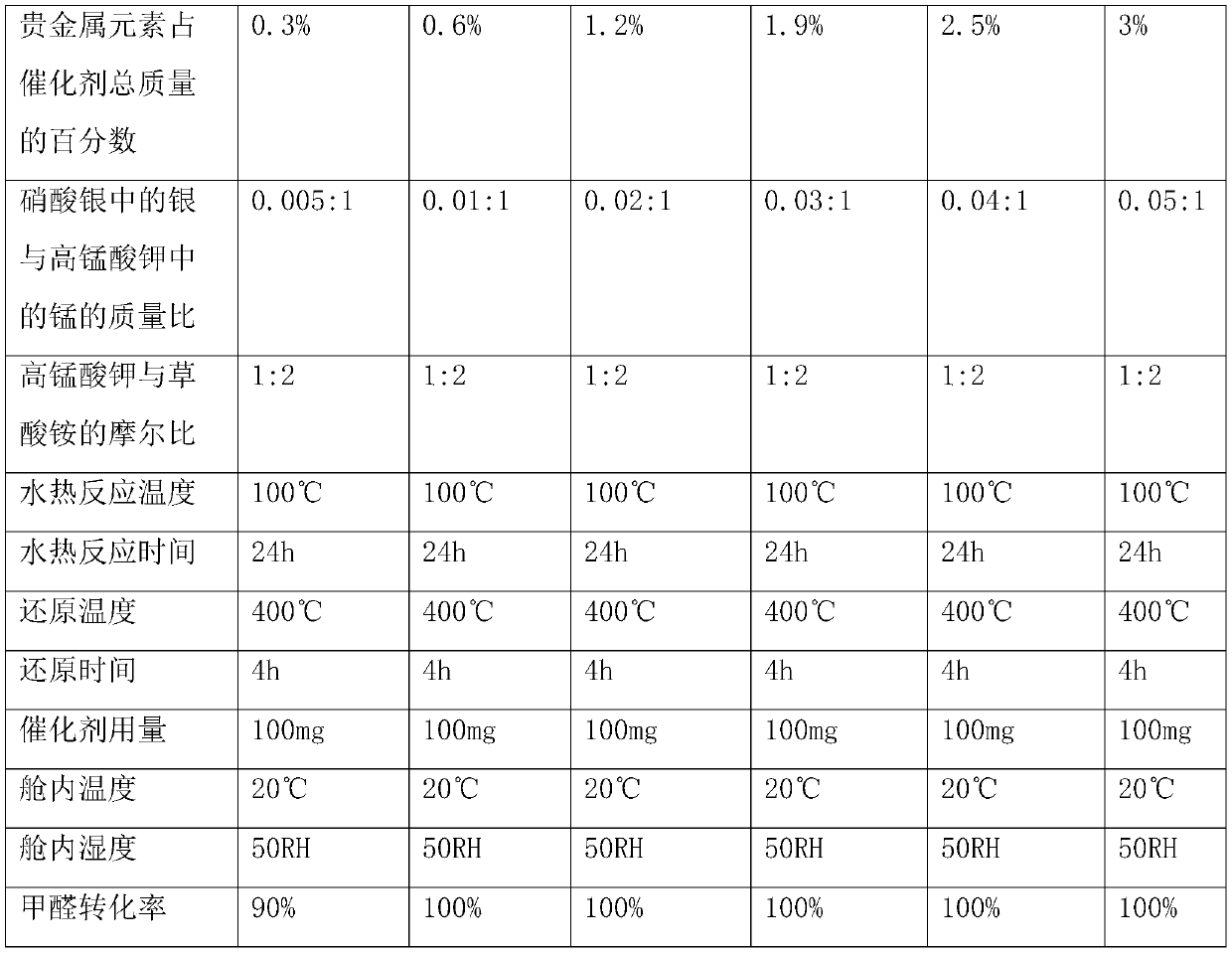

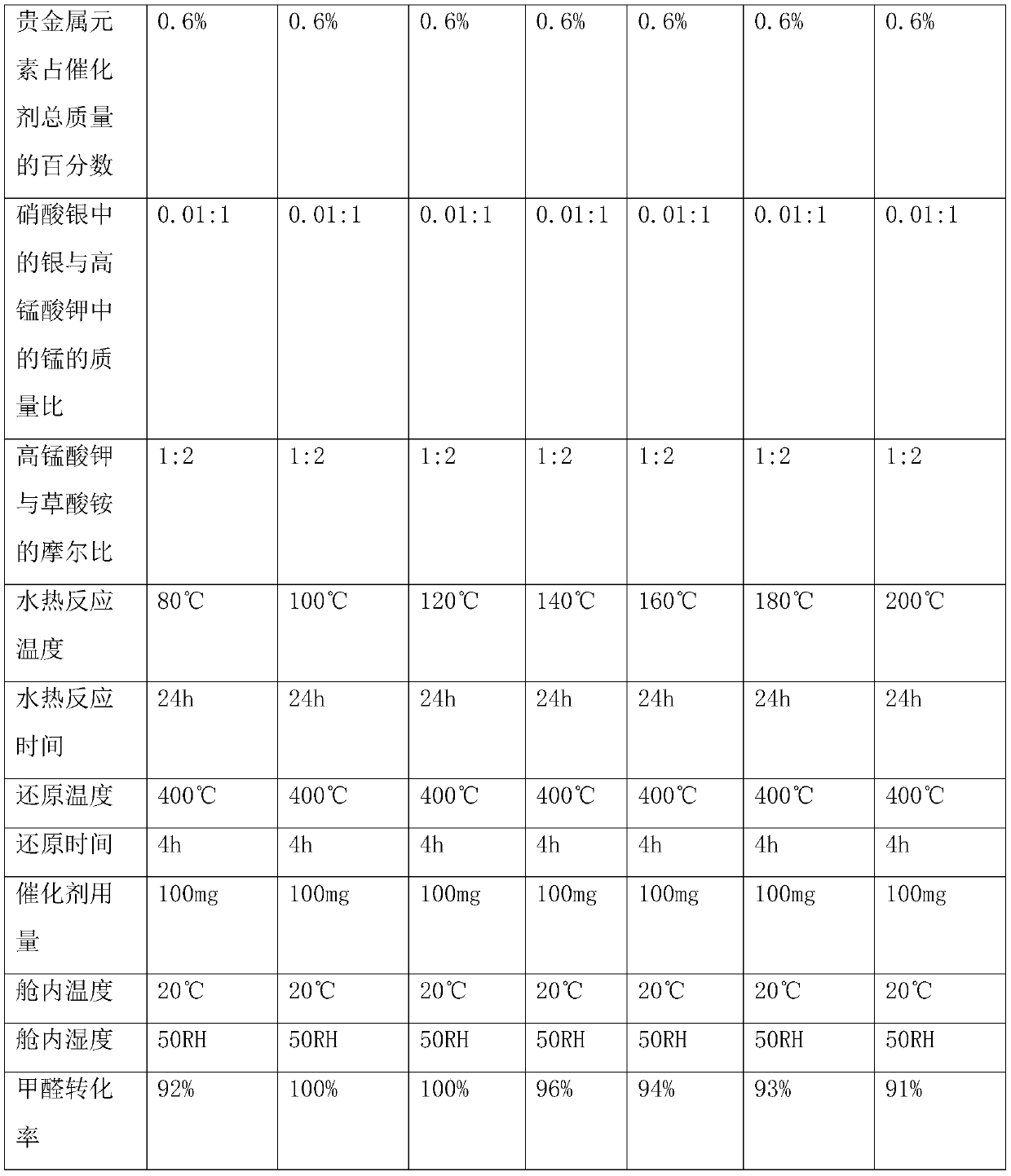

[0040]Add ammonium oxalate and silver nitrate to 30mL0.1mol / L potassium permanganate solution, stir and mix evenly to obtain a mixed solution, wherein the molar ratio of potassium permanganate to ammonium oxalate is 1:2, and the silver in silver nitrate The mass ratio to manganese in potassium permanganate is 0.01:1-0.05:1, and the solvent is deionized water; put the above mixed solution in a 100mL high-pressure reactor, react at 100°C for 24h, and use the obtained slurry Filter and wash with deionized water for 3 times, dry in an oven at 70°C for 12 hours to obtain a powder; put the above powder into a muffle furnace, raise the temperature to 400°C at a rate of 2°C / min in a hydrogen atmosphere, and keep it for 4 hours , and then returned to room temperature, the Ag / MnO 2 catalyst.

[0041] The catalyst prepared in Example 1 is placed in a 3 cubic meter standard formaldehyde test cabin, the temperature in the cabin is 20°C, the relative humidity is 50RH, and the initial conce...

Embodiment 2

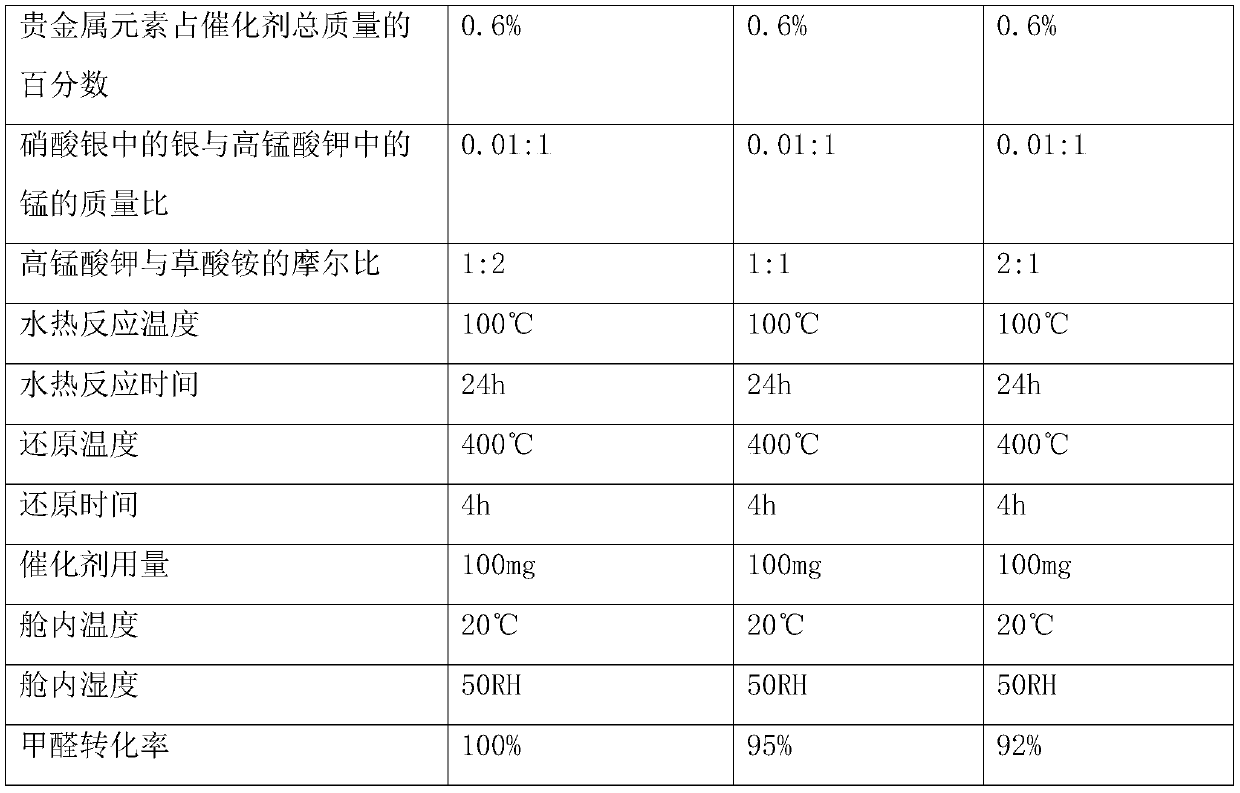

[0046] Add ammonium oxalate and silver nitrate to 30mL0.1mol / L potassium permanganate solution, stir and mix evenly to obtain a mixed solution, wherein the molar ratio of potassium permanganate to ammonium oxalate is 1:2-2:1, nitric acid The mass ratio of the silver in the silver to the manganese in the potassium permanganate is 0.03:1, and the solvent is water; the above mixed solution is placed in a 100mL autoclave, and reacted at 100°C for 24h. Suction filtration and washing for 3 times, put it in a 70°C oven for 12 hours to obtain a powder; put the above powder into a muffle furnace, raise the temperature to 400°C at a rate of 2°C / min in a hydrogen atmosphere, keep it for 4 hours, and then Return to normal temperature to prepare Ag / MnO 2 catalyst.

[0047] The catalyst prepared in Example 2 is placed in a 3 cubic meter standard formaldehyde test cabin, the temperature in the cabin is 20°C, the relative humidity is 50RH, and the initial concentration of formaldehyde is 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com