Insulating packaging material for fresh food and preparation method thereof

A packaging material and food technology, applied in the field of food packaging materials, can solve the problems of no relevant patents or literature reports, and achieve the effects of improving the dissolution rate of cellulose, excellent thermal insulation, and prolonging the preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

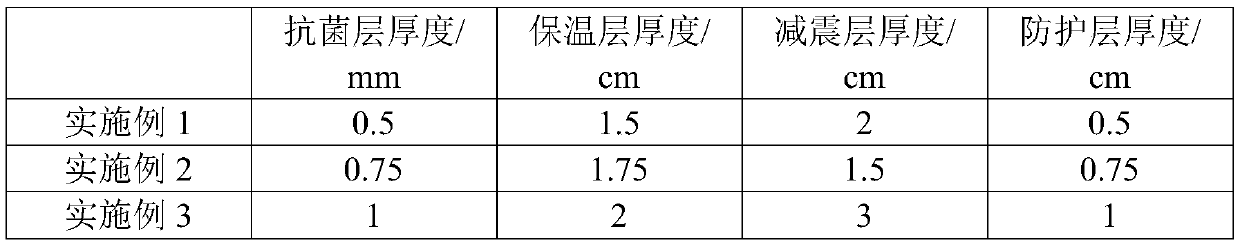

Embodiment 1

[0027] A preparation method for fresh food insulation packaging materials, comprising the following steps:

[0028] (1) Heat and melt 30 parts of ethylene-vinyl acetate copolymer at 100°C. After complete melting, add 20 parts of modified wheat straw powder, 20 parts of waste paper pulp, 10 parts of flax fiber, 5 parts of aluminum borate whiskers, and 4 parts of azobis Diethyl formate, 1 part of silane coupling agent, stir evenly, pour into the mold, dry at 65°C for molding, then heat to 120°C for foaming treatment, after cooling, curling, and cutting, the shock-absorbing layer material is obtained ;

[0029] The preparation method of the modified wheat straw powder is as follows: add the original wheat straw powder, potassium peroxide, and water into a polytetrafluoroethylene-lined reactor in a mass ratio of 2:0.1:1 and seal the reaction for 1 hour, neutralize, filter, After drying, the modified wheat straw powder is obtained;

[0030] (2) After mixing 15 parts of diatom mud...

Embodiment 2

[0034] Preparation method is with embodiment 1, difference is:

[0035] The antibacterial layer is composed of the following raw materials in parts by weight: 3 parts of lysozyme, 2 parts of chlorogenic acid, 4 parts of tea polyphenols, 13 parts of tourmaline powder, 6 parts of microcrystalline graphene, 40 parts of chitosan sol; the chitosan The sol is formed by mixing chitosan and 5% citric acid solution in a weight ratio of 1:7.5;

[0036] The damping layer is composed of the following raw materials in parts by weight: 22.5 parts of modified wheat straw powder, 25 parts of waste paper pulp, 12.5 parts of flax fiber, 7.5 parts of aluminum borate whiskers, 5 parts of diethyl azodicarboxylate, ethylene-vinyl acetate copolymer 35 parts, 1.5 parts of silane coupling agent;

[0037] The insulation layer is composed of the following raw materials in parts by weight: 20 parts of diatom mud, 10 parts of sepiolite wool, 17.5 parts of silica airgel, and 35 parts of silica sol;

[00...

Embodiment 3

[0040] Preparation method is with embodiment 1, difference is:

[0041] The antibacterial layer is composed of the following raw materials in parts by weight: 5 parts of lysozyme, 3 parts of chlorogenic acid, 5 parts of tea polyphenols, 15 parts of tourmaline powder, 7 parts of microcrystalline graphene, 30-50 parts of chitosan sol; Polycan sol is formed by mixing chitosan and 5% citric acid solution in a weight ratio of 1:10;

[0042] The damping layer is composed of the following raw materials in parts by weight: 25 parts of modified wheat straw powder, 30 parts of waste paper pulp, 15 parts of flax fiber, 10 parts of aluminum borate whiskers, 6 parts of diethyl azodicarboxylate, ethylene-vinyl acetate copolymer 40 parts, 2 parts of silane coupling agent;

[0043] The insulation layer is composed of the following raw materials in parts by weight: 25 parts of diatom mud, 15 parts of sepiolite wool, 20 parts of silica airgel, and 40 parts of silica sol;

[0044] The protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com