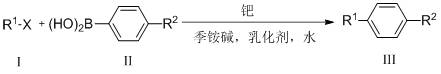

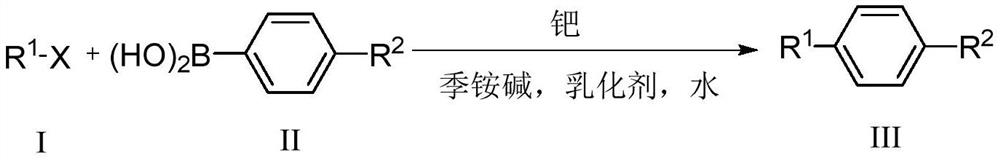

A Palladium-Catalyzed Aqueous Suzuki Cross-Coupling Reaction Without Additional Ligands

A cross-coupling reaction, palladium-catalyzed technology, used in the preparation of catalysts, carbon compound catalysts, organic compounds, etc., can solve the problems of difficult reuse of catalytic systems, increased sewage discharge pressure and consumption costs, and limited application scope. Good recyclability, great practical application value, good recyclability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 0.188g (1.2mmol) 4-methoxyphenylboronic acid, 0.106mL (1.0mmol) bromobenzene, 0.0008g tetraammine palladium dichloride (wherein Pd is 0.0012mmol), 0.40g (2mmol) tetrapropylhydrogen Add ammonium oxide, 0.1mL Triton X-100, and 7mL water into the reaction flask, stir and react at 45°C for 60 minutes, stop the reaction, shake evenly and cool down to room temperature naturally, let it stand for 1 hour, a white solid precipitates, and then place Fully crystallized at -2°C for 2 hours, filtered and washed with water to obtain pure 4-methoxy-1,1'-biphenyl with a yield of 99.0%. 0.188g (1.2mmol) of 4-methoxyphenylboronic acid and 0.106mL (1.0mmol) of bromobenzene were directly added to the filtrate, and the reaction was carried out again according to the above method. The experimental results show that after 8 cycles of the catalyst, the yield of 4-methoxy-1,1'-biphenyl can still reach 70.0%, and the reaction time is extended to 4 hours, 4-methoxy-1,1'-biphenyl The yield of ben...

Embodiment 2

[0020] In the present embodiment, the consumption of tetraamminepalladium dichloride is 0.00002g (wherein Pd is 0.00003mmol), and the reaction time is extended to 3 hours, and other steps are the same as in Example 1 to obtain pure 4-methoxy-1 ,1'-biphenyl, the yield was 99.0%.

Embodiment 3

[0022] In the present embodiment, replace tetraamminepalladium dichloride in embodiment 1 with 0.00018g palladium acetylacetonate (wherein Pd is 0.0006mmol), and stir and react at 45°C for 4 hours, other steps are the same as in embodiment 1, Pure 4-methoxy-1,1'-biphenyl was obtained with a yield of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com