Silicon dioxide loaded chitosan modified waterborne polyurethane acrylate composite emulsion, preparation method therefor and application of composite emulsion

A polyurethane acrylate and chitosan-loaded technology, which is applied in polyurea/polyurethane coatings, applications, antifouling/underwater coatings, etc., can solve the problem of blocking the outward diffusion of water vapor molecules on the surface of the human body, affecting the wearing comfort of leather products, It is easy to breed bacteria and other problems, and achieve the effect of improving antibacterial properties, improving water vapor permeability and antibacterial properties, and improving water vapor permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

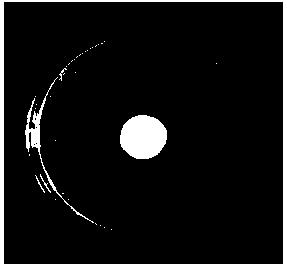

Image

Examples

preparation example Construction

[0036] A kind of preparation method of silicon dioxide loaded chitosan modified water-based polyurethane acrylate composite emulsion of the present invention, prepared a kind of dendritic macroporous silica of amino modification, and it is loaded antibacterial agent chitosan, then Incorporate it into waterborne polyurethane acrylate composite emulsion by physical blending method to obtain macroporous silica-loaded chitosan (MSNs@CS) / waterborne polyurethane acrylate composite emulsion, which can be used as leather finishing agent, specifically prepared The method includes the following steps,

[0037] Step 1, the preparation of aminated macroporous silica, using the co-solvent method with hexadecyl pyridinium bromide as a template, prepared a macroporous silica nanostructure with a central radial channel structure that gradually increases from the inside to the outside. Particles, while the skeleton is uniformly modified with amino groups, there are two methods,

[0038] The f...

Embodiment 1

[0053] Step 1, this step is the existing method for preparing aminated macroporous silica,

[0054] Dissolve 0.5 g of cetylpyridinium bromide and 0.3 g of urea in 15 mL of deionized water, and then add dropwise the pre-mixed oil phase, namely 15 mL of cyclohexane, 0.55 mL of n-butanol and 1.25 g of n-butanol Ethyl silicate, stir at 500r / min at room temperature for 0.5h, then raise the temperature to 70°C and continue the reaction for 12h;

[0055] Wash with acetone and water three times in sequence, place at room temperature for 12 hours, and calcinate the silica at 550°C for 5 hours to obtain macroporous and diporous silica nanoparticles;

[0056] Ultrasonic disperse 0.2g of silica in 30mL of toluene, add dropwise 0.2mL of 3-aminotriethoxysilane, react at 80°C for 12h, and centrifuge to obtain aminated macroporous silica nanoparticles;

[0057] Step 2, ultrasonically disperse 0.4g of chitosan, 0.0234g of sodium chloride and 0.8g of acetic acid in 40mL of deionized water, sti...

Embodiment 2

[0061] Step 1, this step is the method after adjusting the existing method for preparing aminated macroporous silica,

[0062] Dissolve 0.5 g of cetylpyridinium bromide and 0.3 g of urea ultrasonically in 15 mL of deionized water, and the pre-mixed oil phase, namely, 15 mL of cyclohexane, 0.55 mL of n-butanol, and 1.25 g of n-Si Ethyl acetate was slowly added dropwise to the water phase, stirred at room temperature for 30 min at 500 r / min, then the temperature was raised to 70°C, and the reaction was continued at 150 r / min for 10 hours, and 25 μL of pre-mixed 3-aminotri Ethoxysilane and 2.5mL of cyclohexane, and continue to react for 2h;

[0063] The product was washed three times with acetone and water respectively, and placed at room temperature for 12 hours, and the obtained product was calcined at 550° C. for 5 hours to obtain aminated macroporous two-porous silica nanoparticles;

[0064] Step 2, ultrasonically disperse 0.4 g of chitosan, 0.0234 g of sodium chloride and 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com