Hybrid aluminum electrolytic capacitor and manufacturing method thereof

An aluminum electrolytic capacitor, a hybrid technology, applied in the manufacture of electrolytic capacitors, hybrid/electric double layer capacitors, electrolytic capacitors, etc., can solve the problem of unrepaired positive oxide film defects, low electrolyte withstand voltage, low production efficiency, etc. problem, to achieve the effect of not easy short circuit, high withstand voltage and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a hybrid aluminum electrolytic capacitor, comprising the following steps:

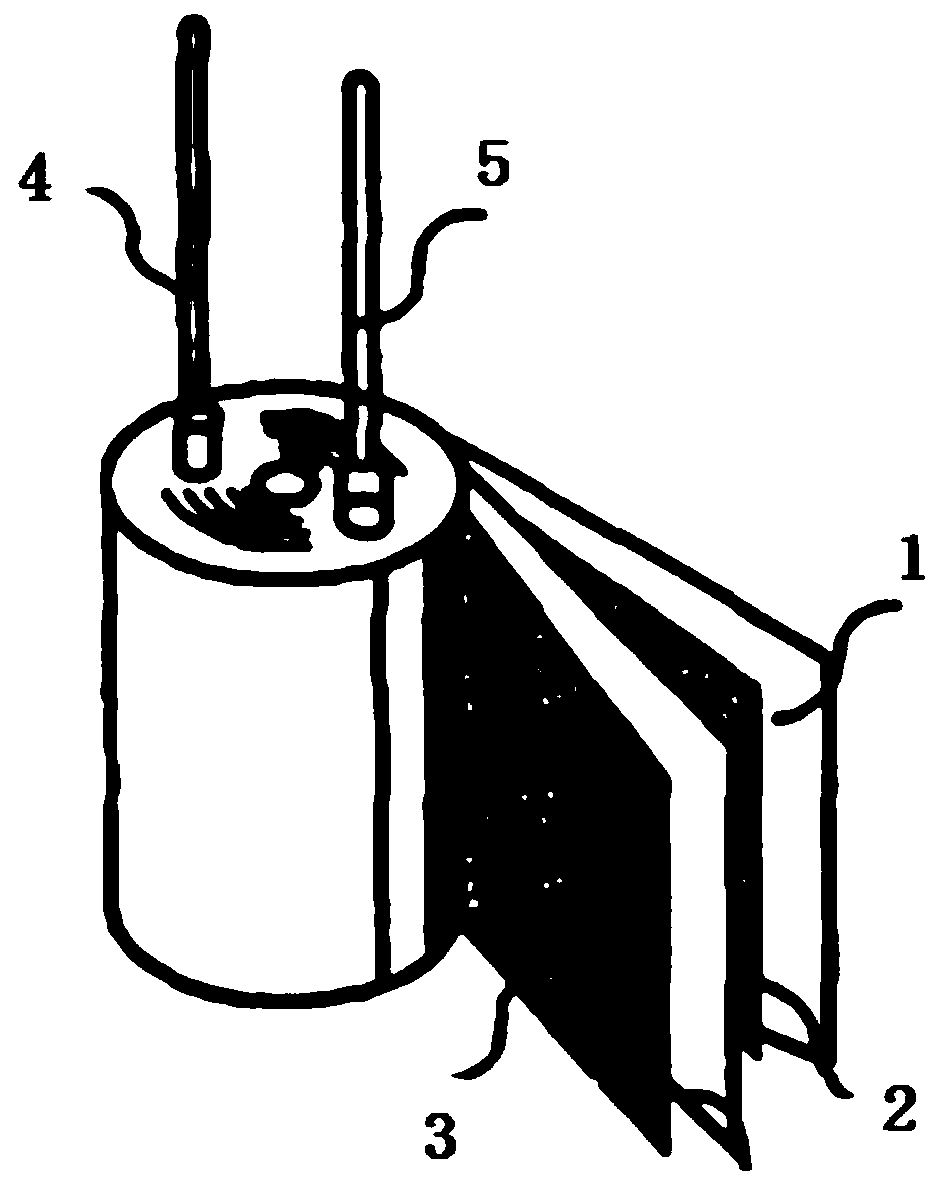

[0041] S100, to make capacitor elements, cut the positive foil, negative foil and electrolytic paper according to the designed size with a stapler, and then rivet the positive and negative guide pins on the positive and negative foils respectively, and then the positive and negative foils The electrolytic paper is wound into a circle, and finally the high temperature resistant insulating tape is wrapped around the periphery of the circle to fix it to form a capacitor element;

[0042] S200, impregnating the capacitor element into a solution, and applying a voltage to the capacitor element according to the withstand voltage of the positive foil, and repairing the defect of the oxide film on the surface of the positive foil of the capacitor element caused by cutting and nailing;

[0043] The formation solution at this stage is ammonium dih...

Embodiment 1

[0062] Prepare a hybrid aluminum electrolytic capacitor according to the method, wherein, in step S100, the positive foil uses aluminum foil with a dielectric film (film withstand voltage 150V) formed by surface corrosion treatment and anodic oxidation treatment, and the negative foil uses surface corrosion treatment and aluminum foil. Aluminum foils with a dielectric film (film withstand voltage 2V) formed by anodizing are cut to a predetermined size, and tab terminals of external lead electrodes are connected to each foil. Positive foil and negative foil passing density 0.35g / cm 3 , Aramid fiber, polyester fiber or cellulose fiber with a thickness of 50um is wound into a non-woven fabric separator to complete the winding of the capacitor element.

[0063] In step S200, a voltage of 150V is applied to the ammonium adipate system forming solution, and a current density of 0.05Ma / pcs is used to repair the oxide film defects on the cut surface of the positive foil caused by cutt...

Embodiment 2

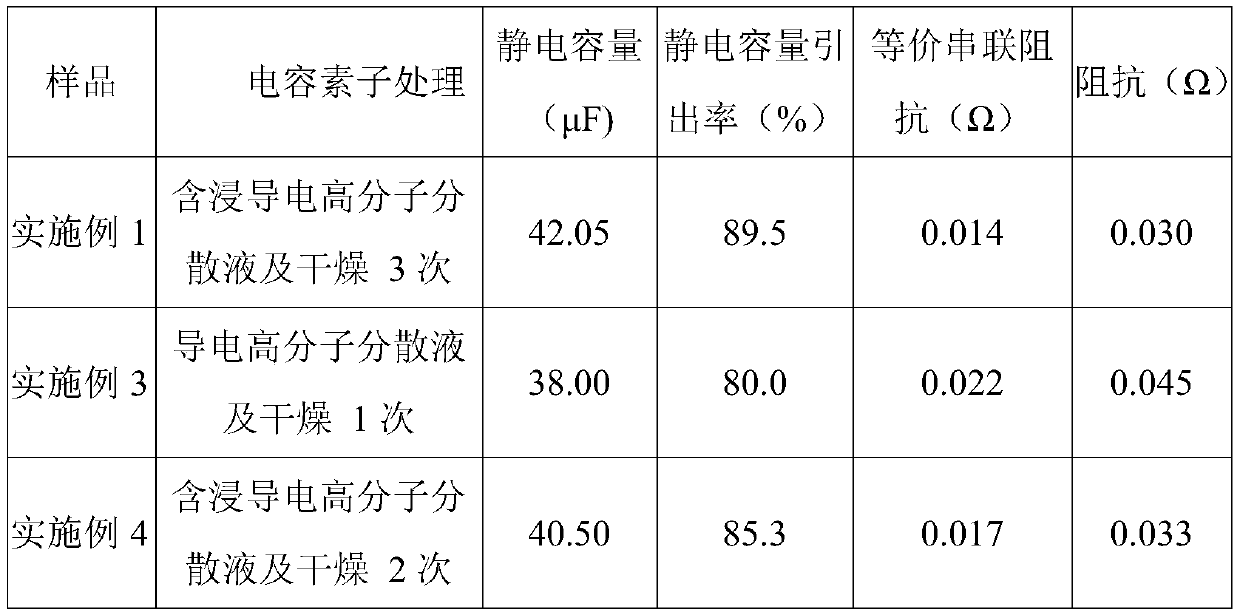

[0070] The operation steps of this embodiment are basically the same as those of Embodiment 1, the difference is that in step S300, the conductive polymer dispersion is impregnated and dried twice, and the film repair liquid impregnated in step S400 is calculated by weight percentage, including: as an organic solvent 50wt% γ-butyrolactone, 35wt% sulfolane and 14.5wt% polyethylene glycol, 0.25wt% benzoic acid as acid, 0.25wt% triethanolamine as amine. A hybrid aluminum electrolytic capacitor having the same specifications as in Example 1 was fabricated.

[0071] Among them, the electrical performance of the capacitor element in step S300 will be tested, and the results are shown in Table 1.

[0072] The test results of the characteristic parameters of the film repair liquid of Example 2: the electrical conductivity is 0.035mS / cm (tested at 28-32°C), the pH is 6.1 (tested at 28-32°C), the water content is 0.18wt%, and the withstand voltage higher than 600V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com