mg/Fe oxide modified biochar nanocomposite material and preparation method thereof

A nanocomposite material and biochar technology, applied in the field of materials, can solve the problems of high energy and chemical substance consumption, slow reaction rate, long reaction time, etc., to increase adsorption sites and active sites, enrich types and quantities, The effect of optimizing the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

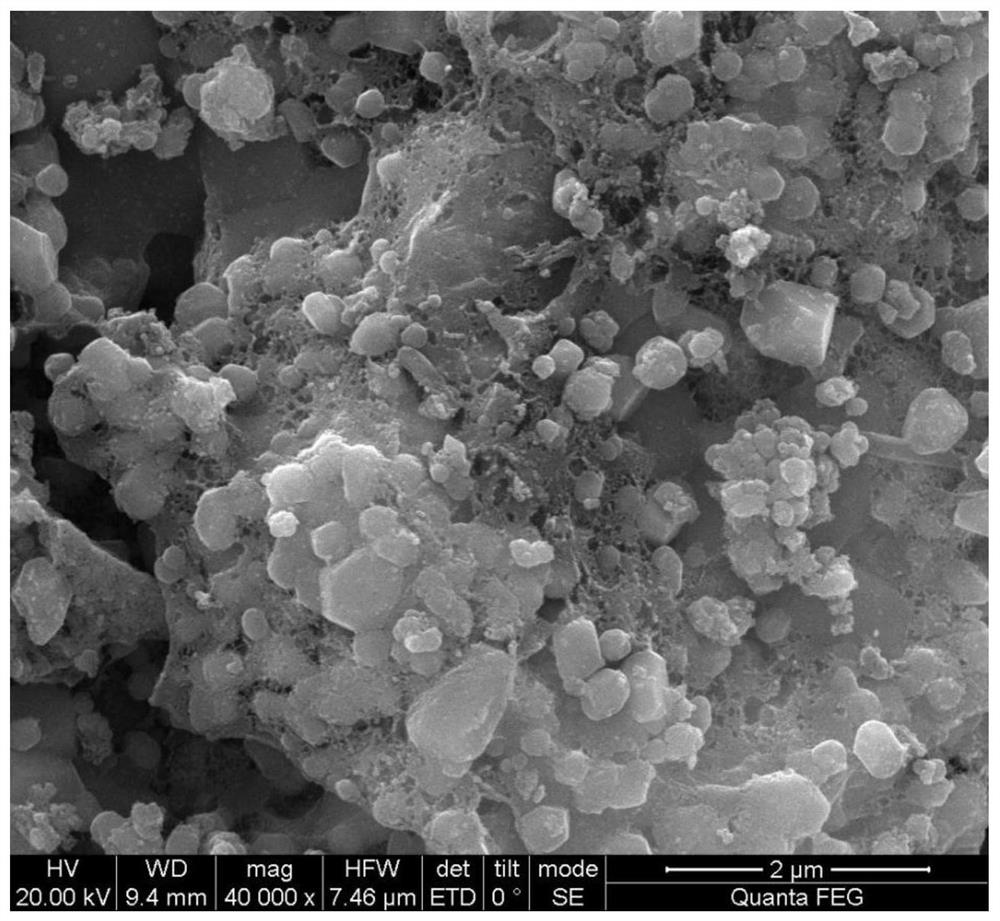

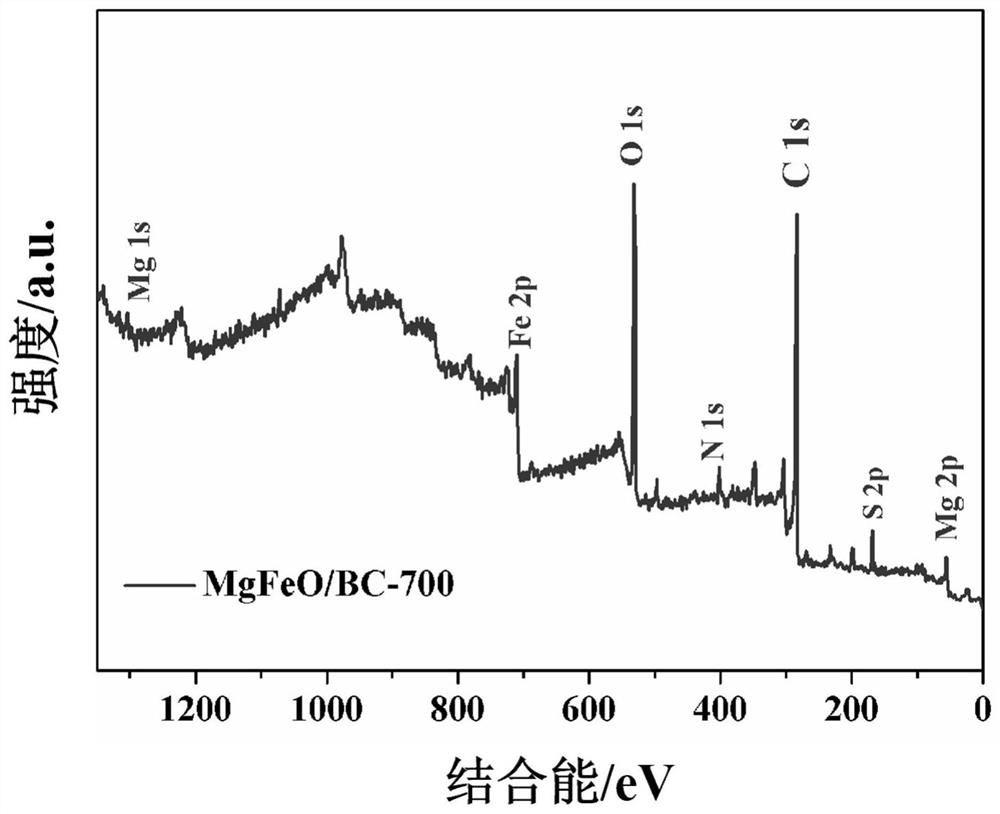

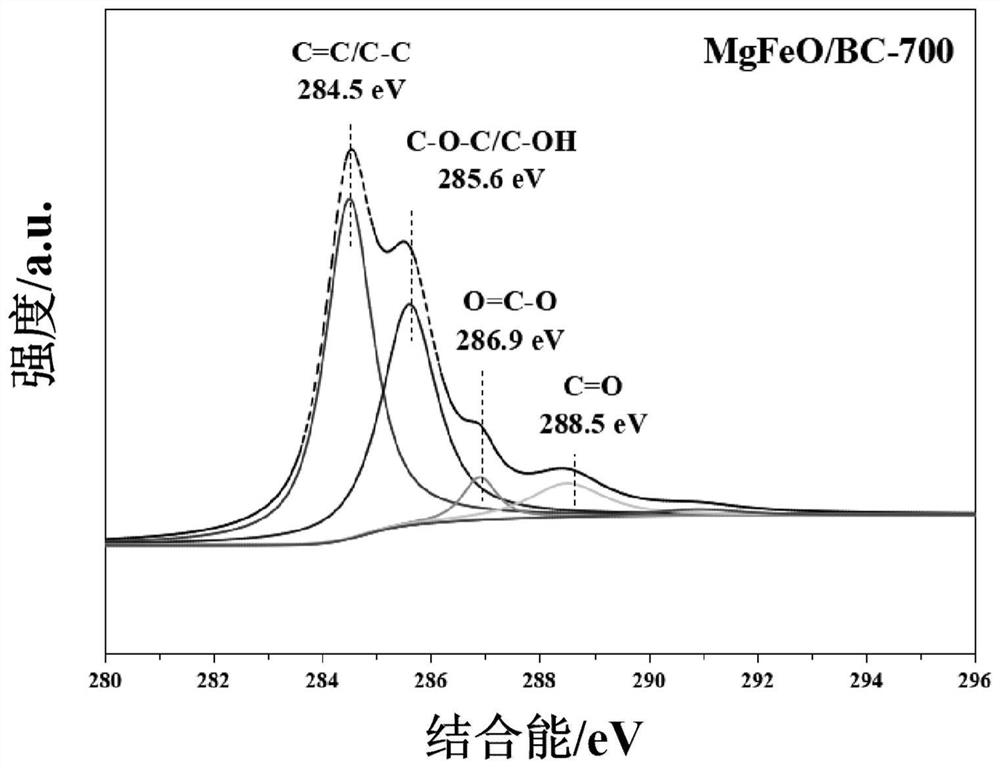

[0041] A method for preparing a biochar nanocomposite material modified by Mg / Fe oxides of the present invention. In this embodiment, the raw material of biochar is corn stalks, and the composite material includes a biochar matrix, and the surface of the matrix is loaded with roasted Mg / Fe oxidized The material is mainly made of corn stalk biomass mixed solution by adding water to corn stalk, and the mixed reaction of corn stalk biomass mixed solution and iron salt and magnesium salt powder is prepared to obtain corn stalk biomass iron and magnesium modified compound, which is passed through a tubular atmosphere furnace in N 2 It is obtained by pyrolyzing the corn stalk biomass iron-magnesium modified compound under the atmosphere, wherein the iron salt and magnesium salt powder are ferric salt and divalent magnesium salt powder.

[0042] A preparation method of the biochar nanocomposite material modified by the Mg / Fe oxide of the above-mentioned present embodiment, specifica...

Embodiment 2

[0051] A kind of biochar nanocomposite material modified by Mg / Fe oxide, its preparation method comprises the following steps:

[0052] (1) Collect waste corn stalks from the corn field, wash the corn stalks with deionized water, and then dry them at 60° C. until their moisture content is 10% to 15% (the drying time is 24 hours). The dried corn stalks are pulverized and passed through a 100-mesh sieve to obtain corn stalk powder.

[0053] (2) Take 5 g of the corn stalk powder obtained in step (1) and add it into deionized water for stirring and dispersing, specifically: stirring and dispersing for 30 minutes in a constant temperature water shaking box at 25°C at a speed of 200 r / min to obtain a mixed suspension A .

[0054] (3) Add 0.04M MgCl to the mixed suspension A obtained in step (2) 2 ·6H 2 O and 0.08M FeCl 3 ·6H 2 O mixed and stirred, the stirring speed was 600r / min, and the stirring time was 30min. At the same time, the sodium hydroxide solution was added dropwise...

Embodiment 3

[0064] A kind of application of biochar nanocomposite material modified by Mg / Fe oxide of the present invention in degrading antibiotics in water body, its application method comprises the following steps:

[0065] (1) Add 30 mL of 5 mg / L sulfamethazine solution, 5 mM ammonium persulfate, and 60 mg Mg / Fe oxide-modified biochar nanocomposite into the reaction vessel to obtain a mixed solution.

[0066] (2) With a concentration of 2mol / L sodium hydroxide solution and a concentration of 2mol / L hydrochloric acid solution, the pH of the mixed solution in the above step (1) is adjusted to 3 by a pH meter, and after 30 minutes of reaction, use a high-efficiency liquid phase Chromatography (HPLC) detects the remaining concentration of sulfamethazine.

[0067] The results show that, using the method of this example, the degradation efficiency of sulfamethazine is about 97.8%. Activated ammonium persulfate to treat sulfamethazine in water, the principle of action is as follows Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com