Method for preparing hollow core-shell structure nano silicon-carbon composite material by taking polyaniline as carbon source and secondary battery applying material

A composite material and core-shell structure technology, which is applied in the field of lithium-ion batteries, can solve problems such as barriers to realization, current collector surface shedding conductivity, SEI film damage, etc., to achieve specific capacity improvement, stable capacity performance, and avoid pulverization failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

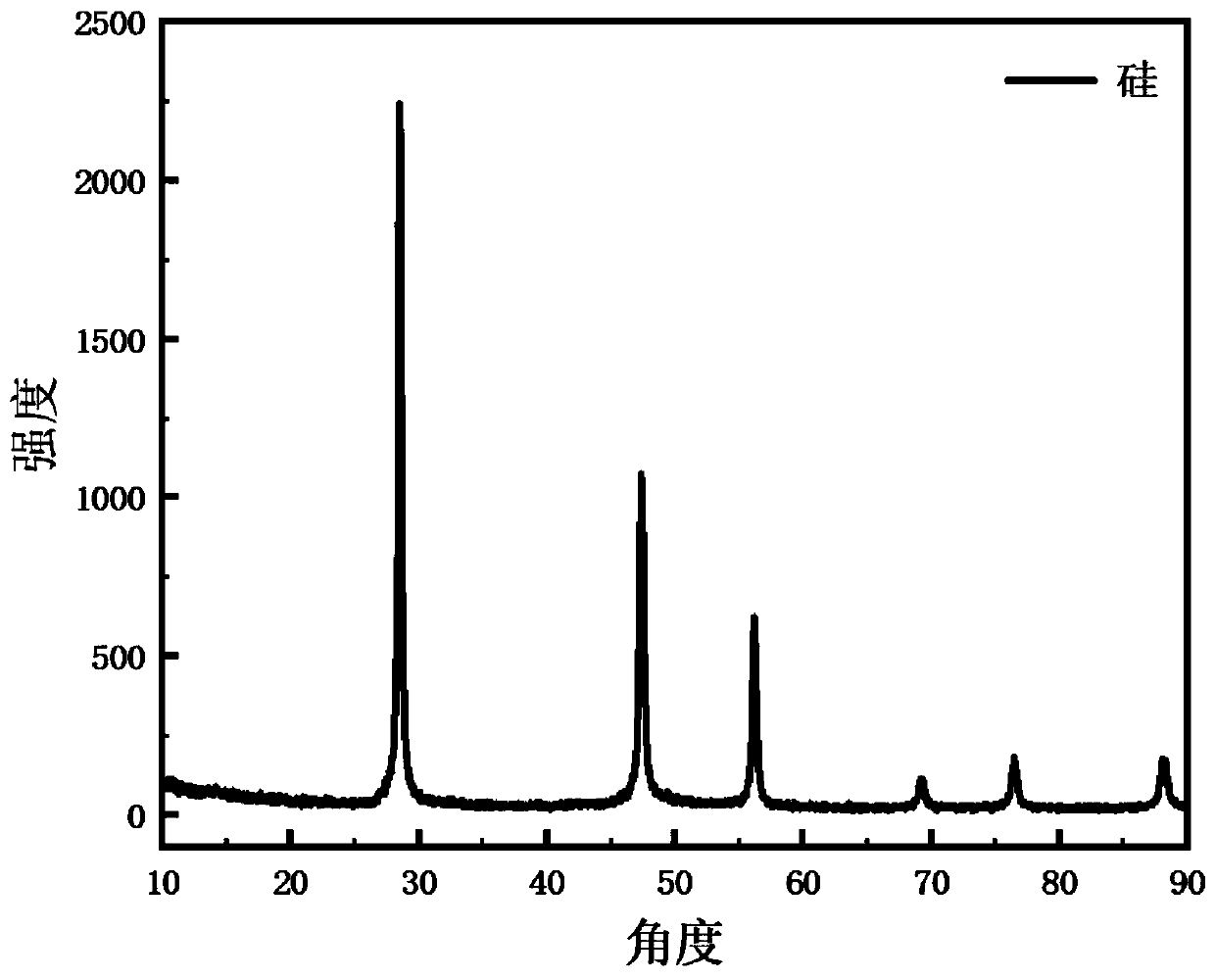

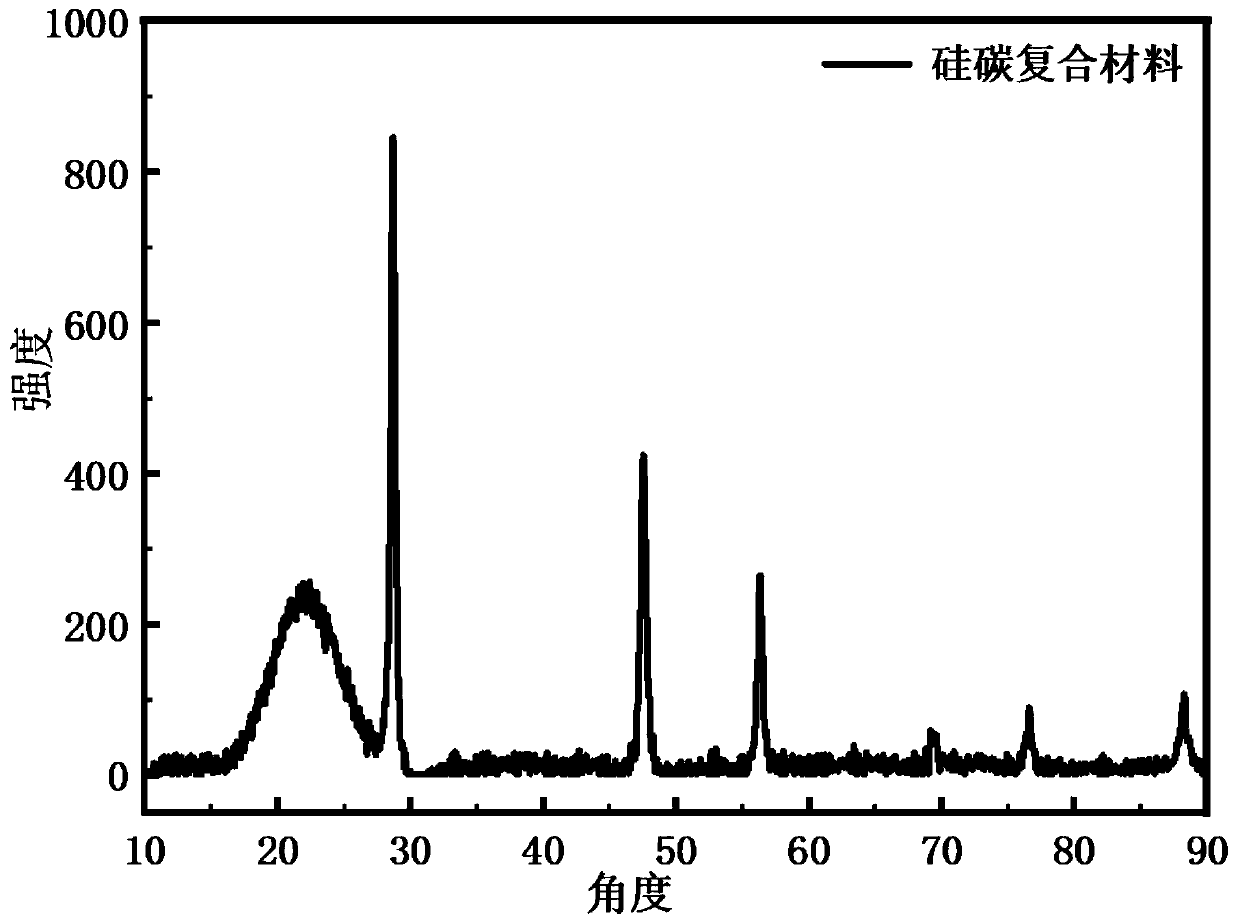

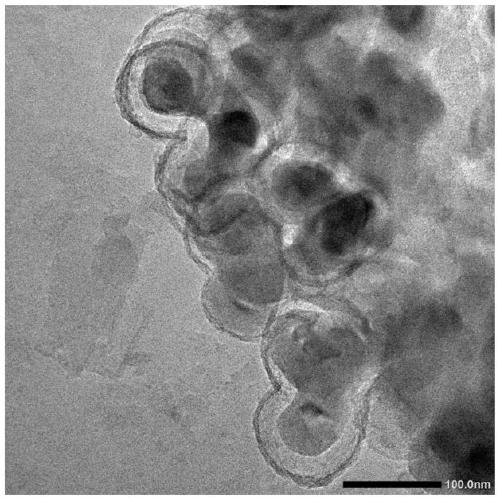

[0030] According to the characteristics of the template etching method, it is preferable to use tetraethyl orthosilicate as the silicon source for preparing the silica template layer. Weigh tetraethyl orthosilicate and nano-silicon particles according to the mass ratio of 10:1, first disperse the silicon nanoparticles in the solution prepared by ethanol and water according to the volume ratio of 4:1 and stir them evenly with a magnetic stirrer, and ultrasonically Disperse for 30 minutes. Then add a certain amount of concentrated ammonia water dropwise into the system, and magnetically stir evenly. Finally, add the previously weighed tetraethyl orthosilicate dropwise to the mixing system, and continue the magnetic stirring reaction at room temperature for more than 10 hours. After fully reacting, high-speed centrifugation separates the silicon nanoparticles coated with the silica template layer. , and centrifuged three times with ethanol. The resulting product was fully dried...

Embodiment example 2

[0033] The carbon-coated nano-silicon composite with hollow core-shell structure prepared in Case 1 was used for secondary lithium-ion batteries. Adopt composite material: acetylene black: CMC=7: 1.5: 1.5 mass ratio to coat the pole piece, as the positive pole of the half battery, use metal lithium as the negative pole, assemble the 32 button half battery, carry out the charge and discharge test with the blue battery, in At a constant temperature of 25°C, a constant current charge and discharge test was performed with a current of C / 20. Figure 4 The charge-discharge curves of the first three cycles of the half-cell are given. Figure 5 The half-cell rate performance test scatter diagram is given. It can be seen that the specific capacity of the composite material has reached 700mAh / g, effectively utilizing the high-capacity performance of silicon, and at the same time, due to the protection of the carbon-coated hollow core-shell structure, it can also exert relatively good c...

Embodiment example 3

[0035] An AC impedance test was performed on the assembled half-cells in Case 2. Using EIS AC impedance spectroscopy for testing. The frequency range is 0.1Hz ~ 1MHz, and the test temperature is room temperature. A comparative impedance test was also carried out on the half-cell mounted on the pole piece coated with pure silicon nanoparticles. Spectrum such as Figure 6 As shown, it can be seen that the as-prepared composite material has lower electrical resistance and higher ionic conductivity compared with pure silicon nanoparticles, which also confirms the effectiveness of the composite with carbon materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com