Method for preparing seafood soy sauce through multi-strain composite fermentation

A technology of composite fermentation and seafood soy sauce, applied in the direction of bacteria, lactobacillus and food processing used in food preparation, can solve the problems of strong fishy smell of seafood, influence of finished product flavor, unpleasantness, etc., and achieve delicious taste and rich seafood flavor , delicious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

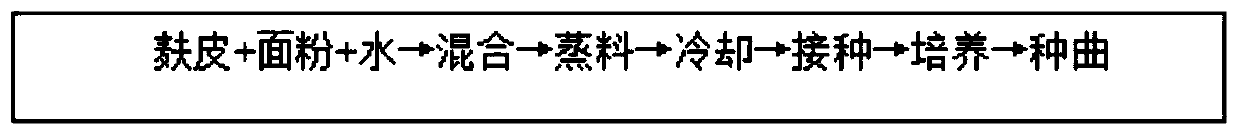

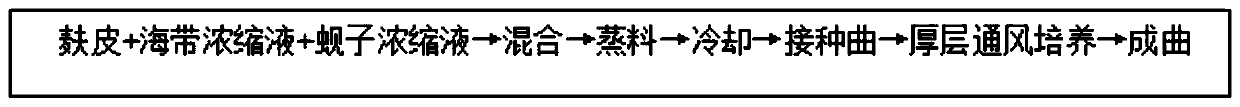

[0033] The main preparation method of seafood soy sauce of the present invention is following steps:

[0034] 1. Pretreatment of dried kelp raw materials

[0035] Dry the kelp to remove the sediment, soak it in 0.3% to 0.5% acetic acid solution for 5 to 10 minutes, take it out and wash it, add pure water according to the mass volume ratio of 1:10 to 1:15, and make a pulp; according to 0.5% of the dry mass of the raw material kelp Add ~1% alginate lyase, control the temperature at 35~45°C, enzymolyze for 1~1.5h, boil the enzymolysis solution for 10min to kill the enzyme; after filtering, concentrate the supernatant to a density of 1.05~1.15g / mL, The concentrate is ready for use.

[0036] 2. Pretreatment of dried clam raw materials

[0037] Soak the dried clam seeds in pure water according to the mass volume ratio of 1:5-1:8, and make a pulp; add the dry powder of Saccharomyces cerevisiae SL-1 according to 1%-5% of the dry mass of raw clam seeds, and culture on a shaking table...

Embodiment 2

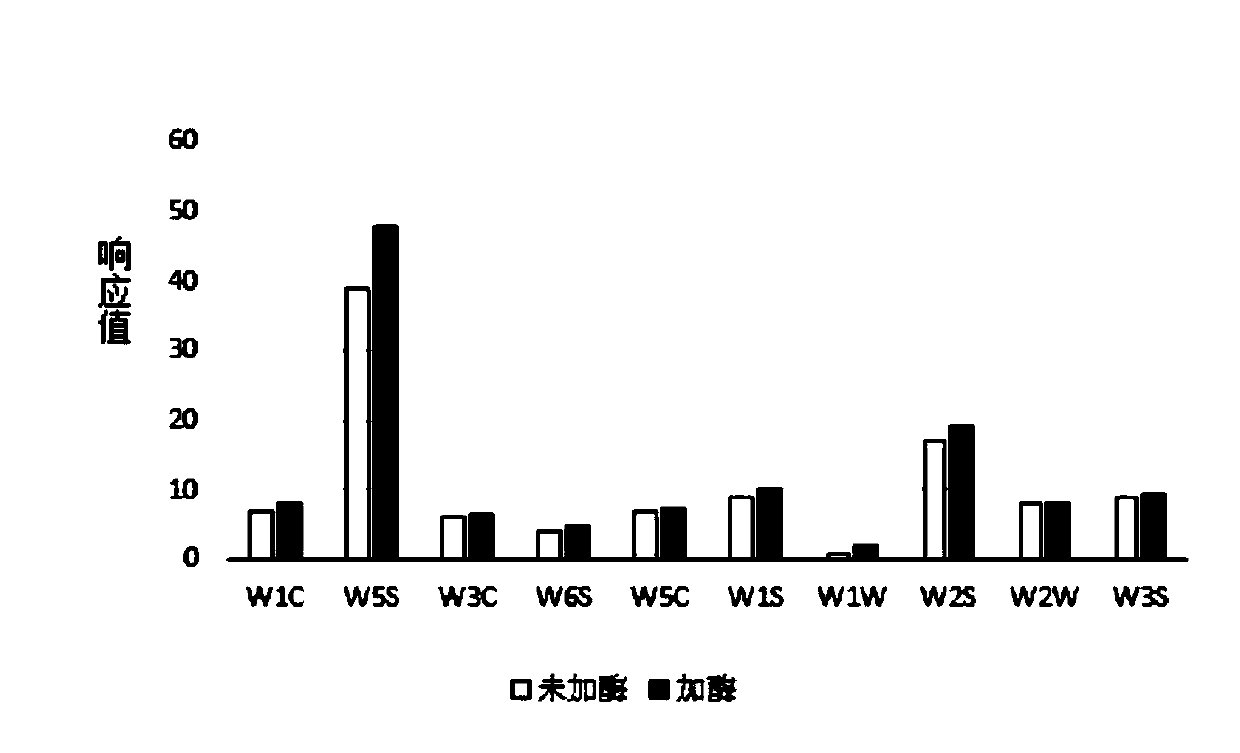

[0046] Example 2: The effect of the processing method of the dried seaweed raw material on the composition of the seaweed concentrated juice and the effect on the mouthfeel of the finished soy sauce

[0047] Mainly detect the following components in the concentrated kelp juice:

[0048] 1. Reducing sugar: Determination by DNS method; the higher the reducing sugar content, the better the enzymatic hydrolysis effect;

[0049] 2. Total sugar: phenol-concentrated sulfuric acid method, using glucose as standard song;

[0050] 3. Solid content: refractometer method, refer to NY / T 2637-2014 "Determination of Soluble Solid Content in Fruits and Vegetables";

[0051] 4. Crude protein: refer to the Kjeldahl method of GB 5009.5-2016 "Determination of Protein in Food";

[0052] 5. Total phenols: refer to GB / T 31740.2-2015 "Tea Polyphenols";

[0053] 6. Mannitol: colorimetric method, sodium periodate hydrochloric acid solution-rhamnose-Nash reagent method, using mannitol standard produc...

Embodiment 3

[0066] Example 3: The effect of the raw material processing method on the dried clam seeds on the components of the clam seed concentrated juice and the effect on the taste of the finished soy sauce

[0067] Soak the dried clams in purified water according to the mass volume ratio of 1:5, and make a pulp; respectively add the dry powder of Saccharomyces cerevisiae CGMCC No.13030, commercially available Angel baker’s yeast, and commercialized brewer’s yeast according to 3% of the dry mass of raw clams. , cultivated on a shaking table for 30 minutes, at a temperature of 37°C, and a rotating speed of 100rpm; then add flavor protease, neutral protease, acid protease, and compound protease according to 0.1%, 0.3, 0.5%, 0.7%, and 0.9% of the dry mass of the raw clams, and heat at 50°C Enzymolysis for 2 hours; boil the enzymolysis solution for 10 minutes to inactivate the enzyme, filter, take the supernatant, and detect the content of free amino acids in it (refer to GB5009.124-2016 "...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com