Shell-based nitrogen-doped activated carbon catalyst prepared by one-step method, product and application

A nutshell-based nitrogen and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalyst, hydrogen halide addition preparation, etc., can solve the problems of complex process, high cost, unsuitable for industrial production, etc. Simplification, manufacturing cost reduction, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

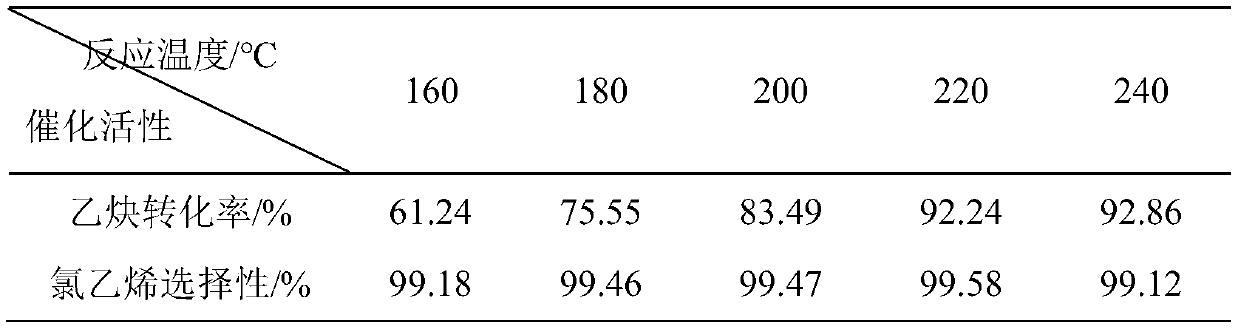

Examples

Embodiment 1

[0026] Blank test: Weigh 30g of husks and place them in an atmosphere furnace, heat up to 500°C at 5°C / min in a nitrogen atmosphere, keep the temperature for 4 hours, and then cool the furnace to obtain activated carbon.

[0027] Catalytic activity evaluation: reaction temperature 180℃, n (C2H2) :n (HCl) =1:1.1, acetylene space velocity 45h -1 , Acetylene conversion rate is 20.84%, and vinyl chloride selectivity is 98.35%.

Embodiment 2

[0029] The step of preparing the nutshell-based nitrogen-doped activated carbon catalyst is as follows:

[0030] 1) Pretreatment of the husk: crush the husk (walnut shell), sieving, and take particles with a particle size of 8-20 mesh, wash and dry for later use; dry at 80°C for 4 hours and then at 150°C;

[0031] 2) Weigh 40mL of deionized water, heat the water bath to 75°C, add 1.2g of melamine, 1.0g of dicyandiamide, and 0.2g of tetraethylammonium chloride, and stir for 1h to obtain a clear impregnating solution; (in other embodiments, the The nitrogen source can also be one or a mixture of two or more of urea, thiourea, cyanamide, hexamethylene diamine, triethanolamine, guanidine hydrochloride, imidazole, pyridine, pyrrole, and amino acids);

[0032] Weigh 40g of walnut shells, add the dipping solution to the walnut shells, stir well, immerse at 75°C for 12h, pour off excess water, keep at 80°C for 4h to dry the surface water stains, and then heat to 105°C to dry to obtain the ca...

Embodiment 3

[0038] The step of preparing the nutshell-based nitrogen-doped activated carbon catalyst is as follows:

[0039] 1) Pretreatment of the husk: crush the husk (walnut shell), sieving, and take particles with a particle size of 8-20 mesh, wash and dry for later use; dry at 80°C for 4 hours and then at 150°C;

[0040] 2) Dilute 1.8 mL of formaldehyde solution (commercially available, with a mass fraction of 37-40%, the same below) to 40 mL with deionized water, adjust the pH to 9.0 with triethylamine, add 0.8 g dicyandiamide and 0.2 g urea, 10 Stir at ℃ for 4h to obtain a clear impregnating solution;

[0041] Weigh 40g of walnut shells, add the dipping solution to the walnut shells, stir well, keep at 10°C for 12h, pour off the excess water, keep at 80°C for 4h to dry the surface water stains, and then heat to 105°C to dry to obtain the catalyst precursor; The loading amount of the amino compound is 2.5% of the mass of the husk;

[0042] 3) The catalyst precursor is placed in an atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com