Modified polyvinyl chloride and preparation method thereof, irradiation-resistant sterilization venous indwelling needle connecting hose and indwelling needle

A technology of polyvinyl chloride and connecting hoses, which is applied in the field of medical materials, can solve the problems of large color yellowing and large pH changes of products, achieve the effect of no aluminum precipitation and improve radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a method for preparing the modified polyvinyl chloride described in the above technical solution, comprising:

[0063]Polyvinyl chloride, main plasticizer, epoxy vegetable oil, calcium soap, zinc soap, hindered amine, phosphite, amorphous calcium silicate and auxiliary stabilizer are melt-extruded and pelletized to obtain modified polyvinyl chloride pellets .

[0064] Wherein, the types, dosages and sources of the above-mentioned various raw materials are consistent with those described in the above-mentioned technical solutions, and will not be repeated here.

[0065] In the present invention, it is preferable to mix the above-mentioned various materials in a high-speed mixer first, stop mixing when the temperature rises to 110-135°C, and then cool to below 60°C to obtain dry powder. Afterwards, the obtained dry powder is melt-extruded and granulated. Wherein, the melt extrusion can be carried out by means of a twin-screw extruder....

Embodiment 1

[0073] According to the silicon:calcium molar ratio of 1:1, weigh 1422.0g sodium metasilicate nonahydrate and calcium nitrate tetrahydrate 1180.8g respectively, and dissolve them in 10L distilled water respectively to obtain calcium nitrate solution and sodium metasilicate nonahydrate solution. Under high-speed stirring (400rpm), the obtained calcium nitrate solution was slowly added dropwise to the sodium metasilicate nonahydrate solution. After the dropwise addition, the stirring reaction was continued for 4h (the whole process was carried out at room temperature at 20±5°C), and then at room temperature. Aging for 6 hours, centrifuged and washed three times with distilled water, dried at 110°C, crushed through a 1000-mesh sieve to obtain amorphous calcium silicate (Si / Ca=1:1).

[0074] On the basis of the above preparation method, the ratio of raw materials was adjusted to prepare amorphous calcium silicate with other Si / Ca ratios, which were used in subsequent examples and c...

Embodiment 2

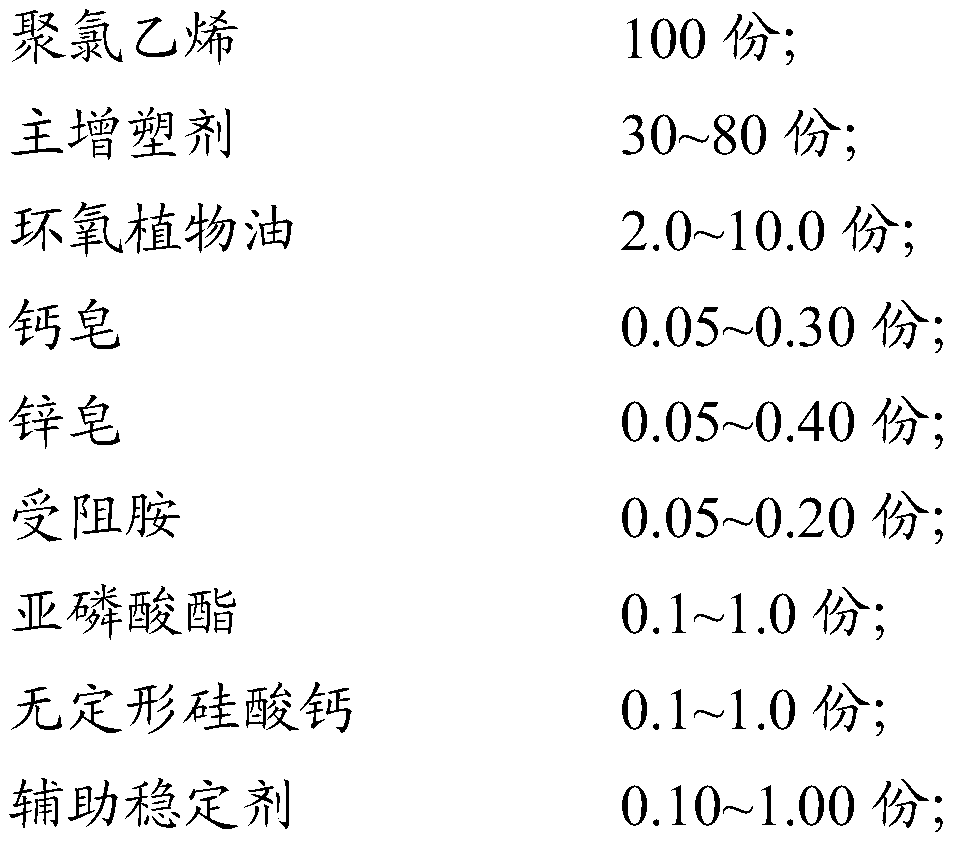

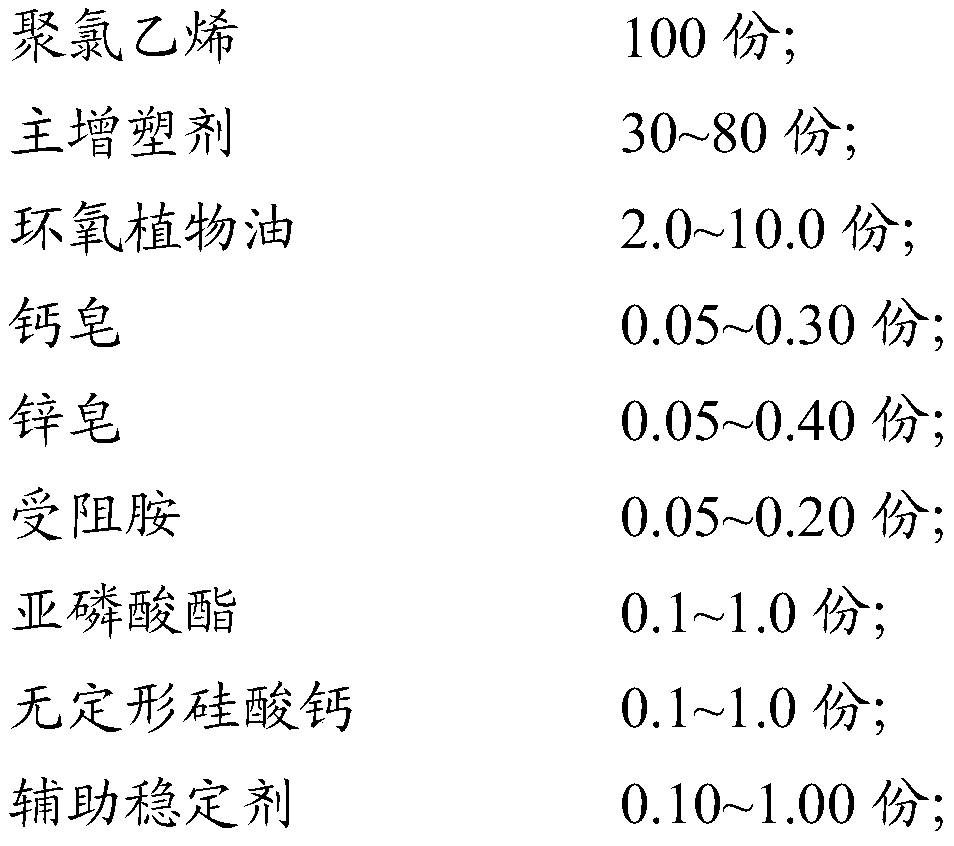

[0076] 1.1 Raw material

[0077]

[0078] 1.2 Preparation

[0079] S1. Put the above-mentioned raw materials into a high-speed mixer, stop mixing when the temperature rises to 130°C, and discharge the materials into a cooler to cool below 60°C to obtain a dry powder.

[0080] S2. The dry powder is granulated through a conical twin-screw extruder, and the extrusion temperature is set to be 160°C, 170°C, 175°C, 175°C, 175°C, 165°C, and 155°C in sequence from the feed port to the die , to obtain radiation-resistant modified PVC pellets after melt extrusion.

[0081] S3. The obtained modified PVC granules are prepared into a connecting hose with an outer diameter of 2.05±0.05mm and an inner diameter of 1.00±0.05mm through a pipe drawing machine.

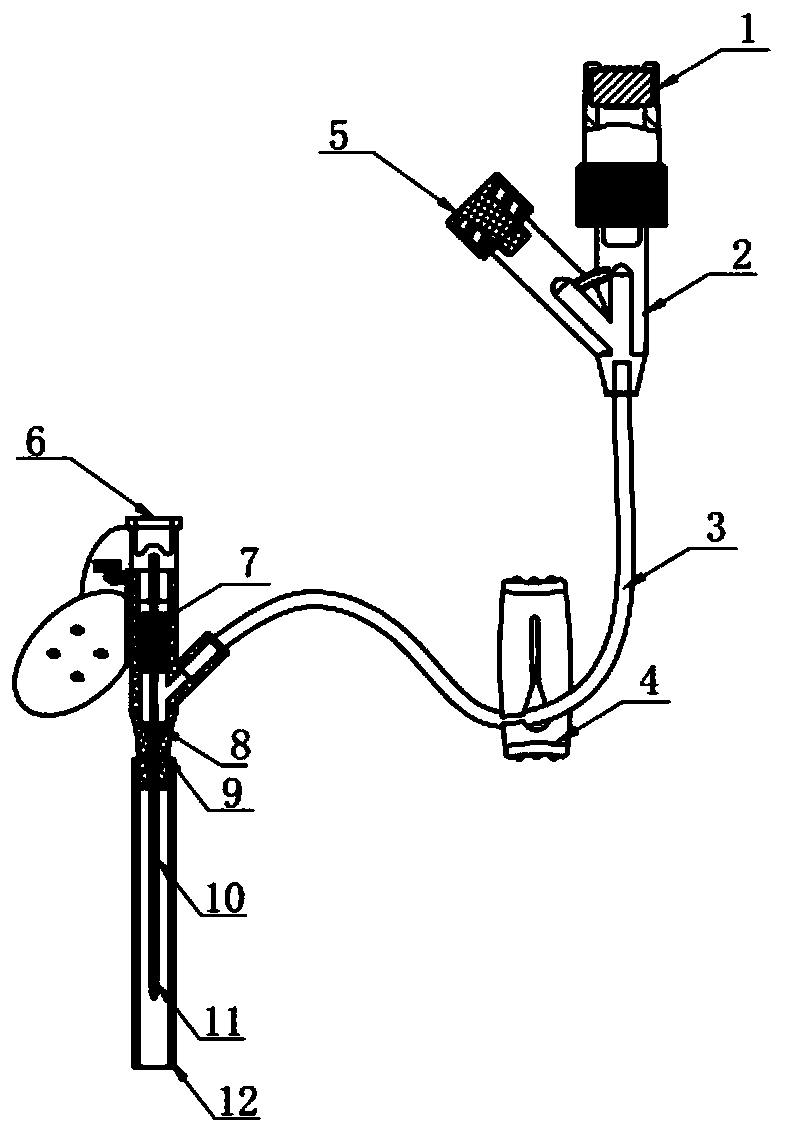

[0082] Use the above connecting hoses in accordance with figure 1 Assemble the IV catheter. See Table 1 for relevant test results such as pH value, yellowness index, and aluminum content of water soluble matter after irradiation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com