Method for treating biogas slurry

A technology of biogas slurry and concentrate, applied in water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve problems such as exceeding standards and endangering human health, and achieve reduced membrane pollution, stable changes in heavy metal content, biogas The effect of fluid volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 Utilizes the method of aerobic activated sludge method to process biogas slurry

[0054] refer to figure 1 As shown in the flowchart, 2.0L pig farm liquid digestate is sent to the aerobic bioreactor (Bioreactor), and the bioreactor is treated in the presence of 2.0L aerobic activated sludge. The parameters are set as follows: Sludge inoculation The amount (MLSS) is 12g / L, the hydraulic retention time (HRT) is 2 days, the dissolved oxygen (DO) concentration is controlled at 4.0mg / L, and the aeration rate is 0.6-1.6L / min. The liquid after treatment is named aerobic effluent.

Embodiment 2

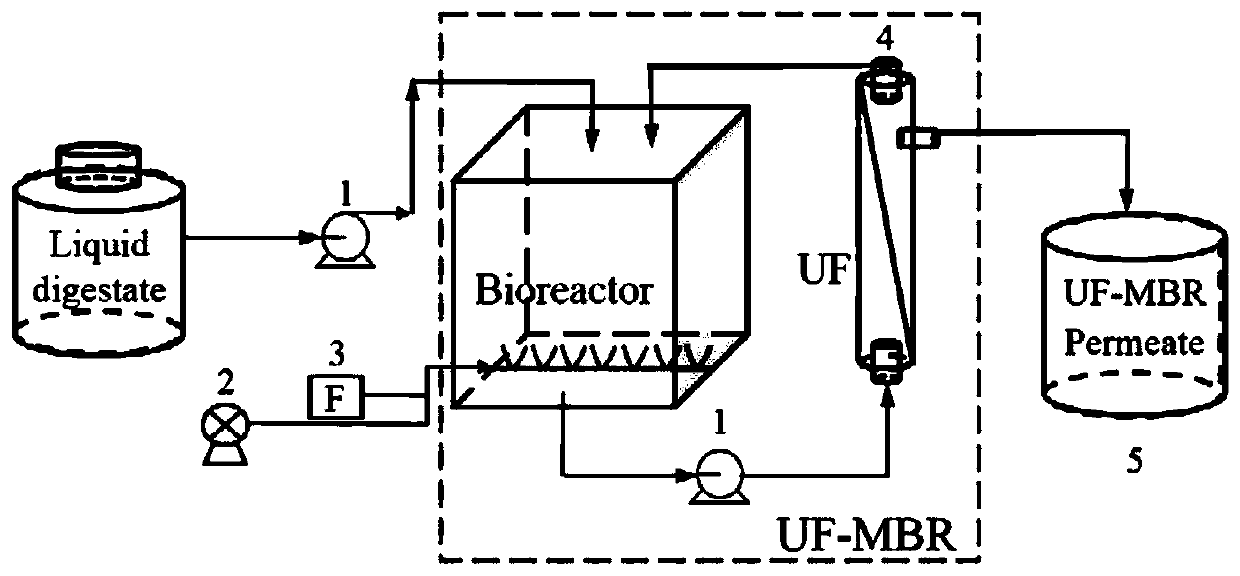

[0055] Embodiment 2 utilizes ultrafiltration-membrane bioreactor (UF-MBR) to process the method for biogas slurry

[0056] The ultrafiltration-membrane bioreactor is composed of an aerobic bioreactor and an ultrafiltration membrane. The treatment method is as follows:

[0057] (1) Aerobic activated sludge treatment: refer to figure 2 As shown in the flowchart, 2.0L pig farm biogas slurry is sent to the ultrafiltration-membrane bioreactor (UF-MBR), first passed through the aerobic bioreactor (Bioreactor), and the biogas is treated in the presence of 2.0L aerobic activated sludge The treatment parameters are set as follows: sludge inoculum size (MLSS) is 12g / L, hydraulic retention time (HRT) is 2 days, dissolved oxygen (DO) concentration is controlled at 4.0mg / L, and aeration rate is 0.6-1.6 L / min. The liquid after treatment is named aerobic effluent.

[0058] (2) Ultrafiltration membrane separation: Then the aerobic effluent after step (1) aerobic activated sludge treatment...

Embodiment 3

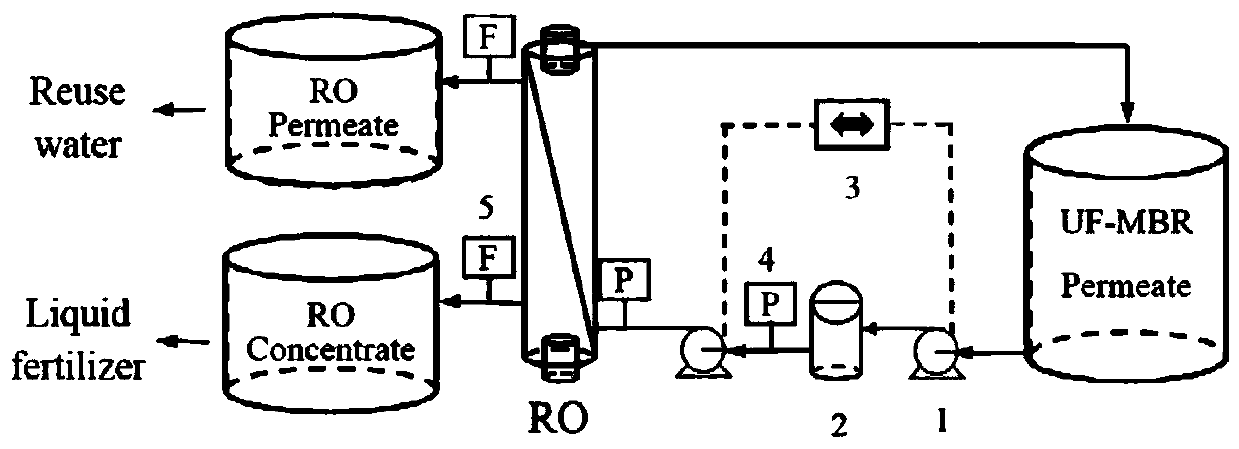

[0059] Embodiment 3 Utilizes the method of MBR-RO combined process to treat biogas slurry

[0060] Step 1, ultrafiltration-membrane bioreactor (UF-MBR) treatment

[0061] With embodiment 2.

[0062] Step 2. Reverse osmosis membrane (RO) concentration treatment

[0063] refer to image 3 As shown in the flow chart, the effluent (UF-MBR treatment solution) after the ultrafiltration membrane separation treatment in step 1 is sent into the sampling barrel, enters the 5 μm security filter, and then is sent into the reverse osmosis membrane (RO, pore size ≤1nm) for concentration and separation to obtain RO concentrate and RO permeate; the RO permeate is collected in the RO permeate tank, and the RO concentrate is returned to the sampling barrel for circulation. When the concentration ratio of the finally obtained RO concentrate is 10 times, a 10-fold biogas slurry membrane concentrate is obtained.

[0064] The concentration ratio refers to the ratio of the feed water volume of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com