Composite denitration agent and preparation method thereof

A technology of denitrification agent and oxidant, applied in the field of denitrification, can solve the problems of high production cost of denitrification agent, unsatisfactory denitrification effect, poor thermal stability, etc., and achieve high thermal stability, simple and easy-to-control preparation method, and high thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

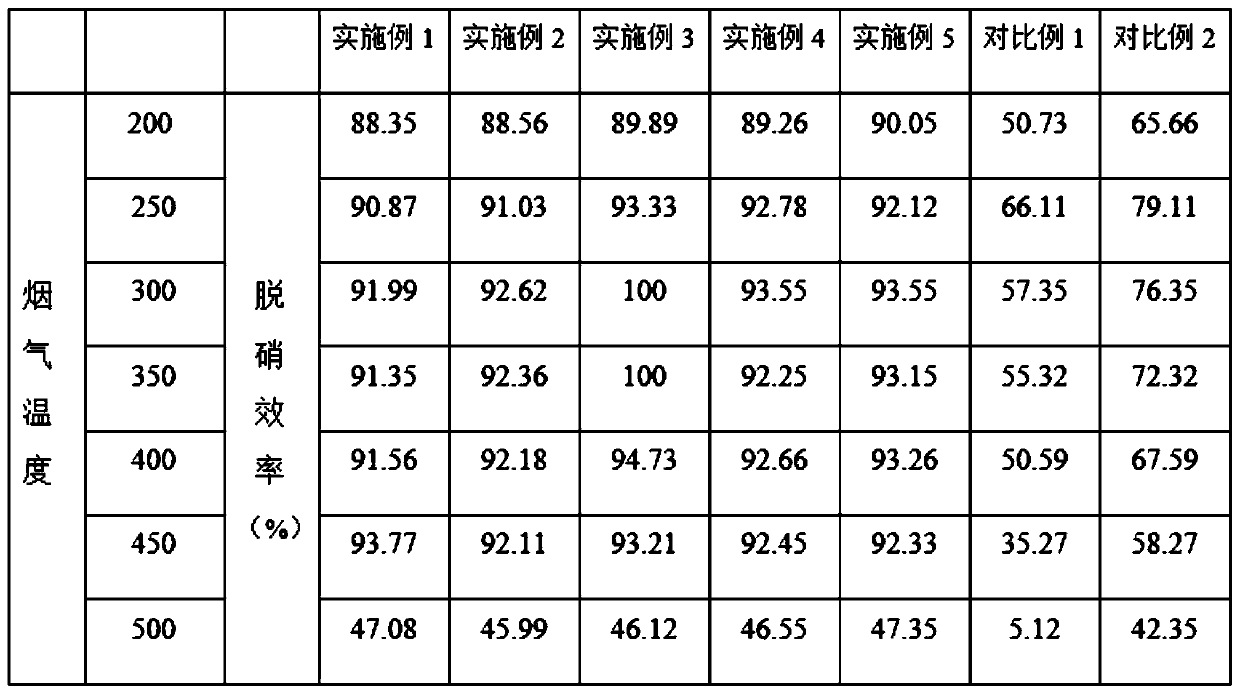

Examples

Embodiment 1

[0026] Take 5Kg of iron oxide, 5Kg of lanthanum oxide, 5Kg of barium oxide and 5Kg of urea, mix them uniformly, and conduct an activation heat treatment at 200°C for 2 hours under a nitrogen atmosphere to obtain composition A; take 30Kg of talcum powder, 10Kg of layered silicate and 1Kg of permanganese Potassium oxide is placed in an appropriate amount of ethanol and water mixed solution (the volume ratio of ethanol and water is 1:1), and the pH is adjusted to 3.5 with acid to obtain composition B; 5Kg potassium oxide, 2Kg organic viscose are added to the mixer Binder, 5Kg inorganic binder, 1Kg carboxymethyl cellulose, 0.5Kg surfactant, 1Kg dispersant and 0.1Kg glycerin are stirred while heating until the temperature rises to 80° C. to obtain composition C; A. Composition B and composition C are added to the mixer together, mixed with water to obtain mud; knead the mud, and then granulate or extrude; dry at 120°C for 3 hours, and then calcined at 300°C for 24 hours, The compou...

Embodiment 2

[0028] Take 10Kg of iron oxide, 10Kg of lanthanum oxide, 10Kg of barium oxide and 10Kg of urea, mix them uniformly, and conduct an activation heat treatment at 500°C for 3 hours under a nitrogen atmosphere to obtain composition A; take 80Kg of talcum powder, 20Kg of layered silicate and 5Kg of high manganese Potassium oxide is placed together in a mixed solution of an appropriate amount of ethanol and water (the volume ratio of ethanol and water is 1:1), and the pH is adjusted to 3.5 with acid to obtain composition B; 10Kg potassium oxide, 5Kg organic Binder, 20Kg inorganic binder, 5Kg carboxymethyl cellulose, 2Kg surface active agent, 10Kg dispersant and 10Kg glycerin, stir while heating, until temperature rises to 80 ℃, obtain composition C; Composition A , composition B, and composition C are put into a mixer together, mixed with water to obtain mud; knead the mud, and then granulate or extrude; dry at 200°C for 5h, and then calcined at 800°C for 72h to obtain Composite den...

Embodiment 3

[0030] Take 7Kg of iron oxide, 7Kg of lanthanum oxide, 7Kg of barium oxide and 7Kg of urea, mix them evenly, and conduct an activation heat treatment at 300°C for 2.5 hours under nitrogen atmosphere to obtain composition A; take 55Kg of talcum powder and 15Kg of layered silicate and 3Kg of Potassium manganate is placed together in a mixed solution of an appropriate amount of ethanol and water (the volume ratio of ethanol and water is 1:1), and the pH is adjusted to 3.5 with acid to obtain composition B; 7Kg potassium oxide, 3Kg Organic binder, 12Kg inorganic binder, 3Kg carboxymethyl cellulose, 1Kg surface active agent, 5Kg dispersant and 5Kg glycerin, stir while heating, until temperature rises to 80 ℃, obtain composition C; Composition A. Composition B and composition C are added to the mixer together, mixed with water to obtain mud; knead the mud, then granulate or extrude; dry at 160°C for 4 hours, and then calcined at 550°C for 48 hours, Obtain the finished compound denit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com