A method for recovering and enriching precious metals in complex materials of low-grade precious metals

A precious metal, low-grade technology, applied in the field of rare and precious metal metallurgy, can solve the problem of reduction, achieve high enrichment multiples, avoid copper oxidation, and reduce waste copper wire consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

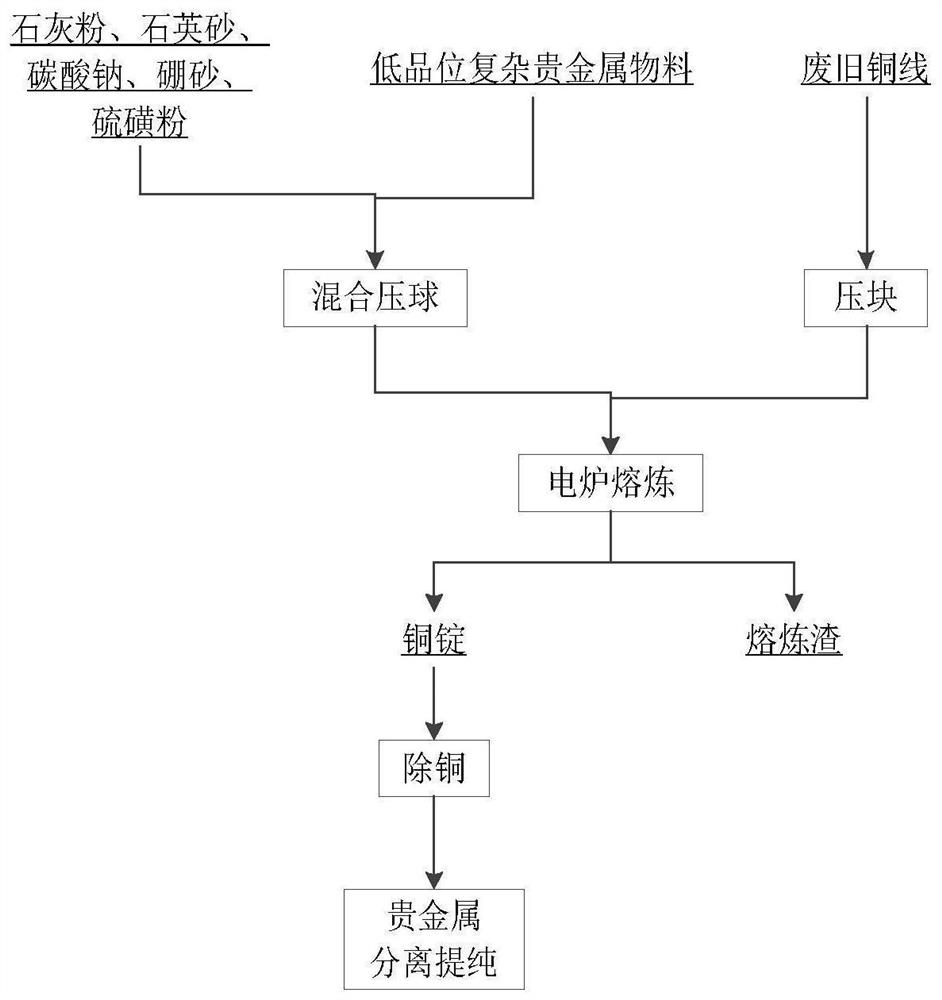

Method used

Image

Examples

Embodiment 1

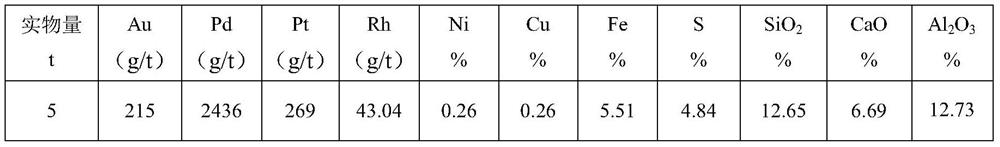

[0019] Take spent 5t of precious metal-containing catalysts. Referring to Table 1, the spent noble metal-containing catalysts included the following chemical compositions:

[0020] The chemical composition that the precious metal-containing catalyst of table 1 failure comprises

[0021]

[0022] Utilize a metal briquetting machine to extrude the scrap copper wire into several scrap copper wire briquettes each weighing 10kg. According to the actual content of silica, calcium oxide and alumina in Table 1, add 865kg of industrial lime, 2.44t of industrial quartz sand, 100kg of sodium carbonate, 25kg of borax, and 200kg of sulfur to the spent catalyst and mix them with water. Mix well before using The briquetting machine makes pellets, and the pellets are dried. The mass ratio of silica, calcium oxide, alumina, sodium oxide, boron oxide, and sulfur in the final pellets is 62.3:21.6:14.6:1.4:0.68:4.5. After arcing in the electric arc furnace, gradually add 180kg of waste coppe...

Embodiment 2

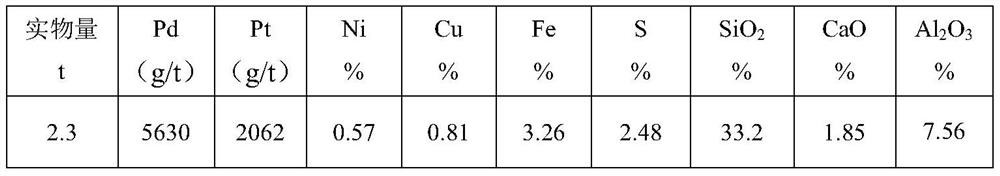

[0024] Take the precious metal-containing complex material after wet leaching, see Table 2, the precious metal-containing complex material includes the following chemical components:

[0025] Table 2 Chemical Composition Included in Complex Materials Containing Precious Metals

[0026]

[0027] Utilize a metal briquetting machine to extrude the scrap copper wire into several scrap copper wire briquettes each weighing 10kg. According to the actual content of silica, calcium oxide and alumina in Table 1, add 256kg of industrial lime, 0.8t of industrial quartz sand, 19.2kg of sodium carbonate, 7.32kg of borax, 50kg of sulfur and water to the spent catalyst and mix well. Finally, the pellets are made into pellets using a briquette machine, and the pellets are dried. The mass ratio of silica, calcium oxide, alumina, sodium oxide, boron oxide, and sulfur in the final pellets is 63.5:22.2:14.5:1.6:0.61:4.5 . After arcing in the electric arc furnace, gradually add 150kg of waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com