Alginate fiber-containing spunlace fabric capable of absorbing water for gelation, and preparation method and application of spunlace fabric

A water-absorbing gel and seaweed fiber technology, which is applied in fiber treatment, cosmetic preparations, textiles and papermaking, etc., can solve the problems of limited application fields, high cost of facial masks, and complicated processes, so as to improve comprehensive performance and facilitate removal and use , the effect of speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

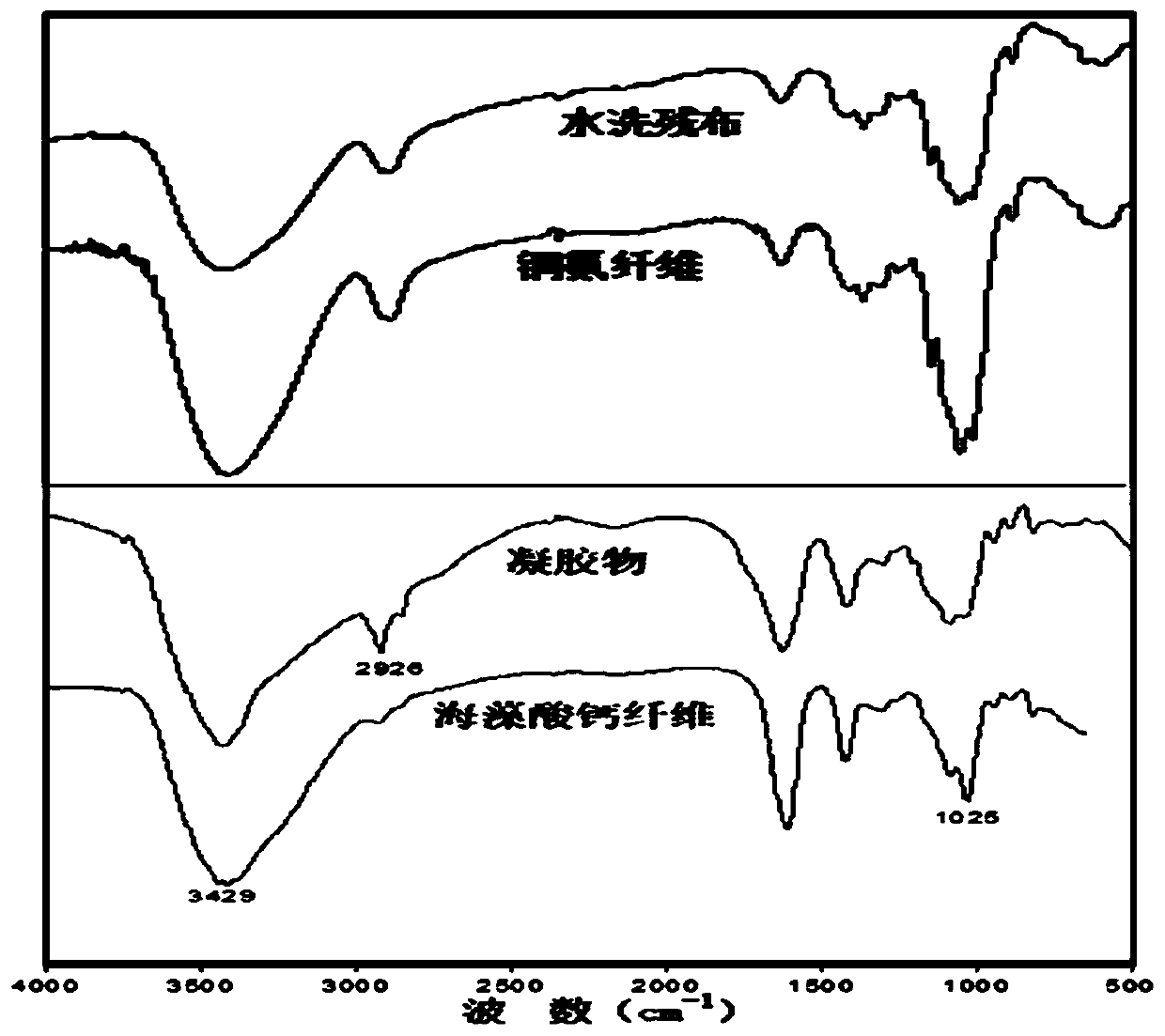

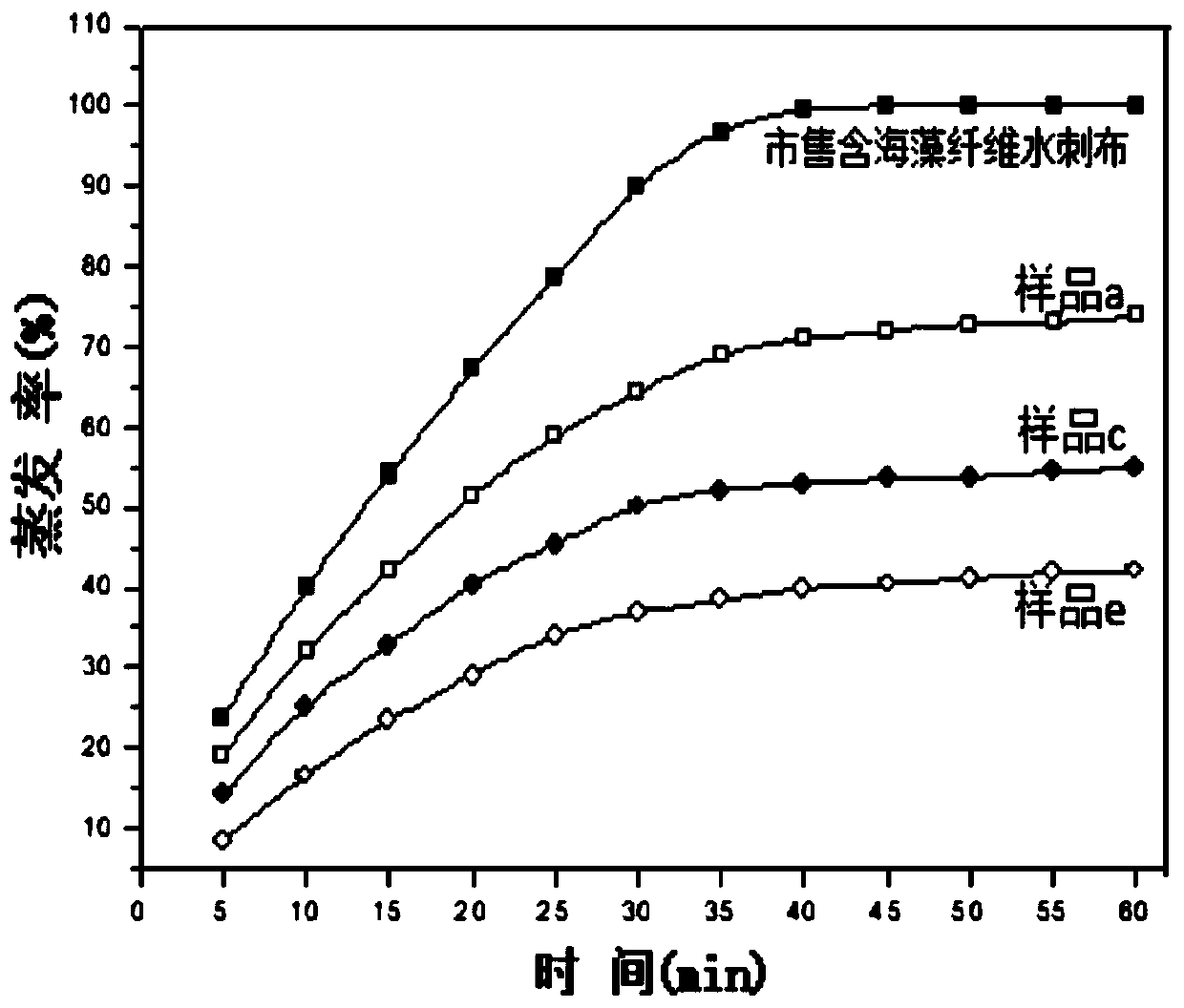

[0052]Weigh 10 kg, 15 kg, 20 kg, 25 kg, 30 kg and 32 kg of commercially available calcium alginate fiber, and then weigh 90 kg, 85 kg, 80 kg, 75 kg, 70 kg and 68 kg respectively For commercially available cupro fibers, the two fibers are pre-opened separately, and then each part of calcium alginate fiber is mechanically blended with the corresponding amount of cupro fibers to obtain six parts of blended fibers, and the mass of each part of blended fibers is equal to 100 kg; finely open the blended fibers, then feed them into a blending opener for processing, then feed them into a carding machine for carding, and output a uniformly mixed fiber web; feed the fiber web into a web-laying machine for crossover Lay the web, and then carry out multi-stage small multiple drafting on the laminated fiber web by a random drafting machine to obtain a fiber web with an interpenetrating network structure; use a sodium sulfate high-pressure aqueous solution jet with a concentration of 10g / L t...

Embodiment 2

[0067] Weigh 20 kg of commercially available calcium alginate fiber and 80 kg of tencel fiber respectively, pre-open the two fibers separately, and then mechanically blend them; finely open the blended fibers, and then feed them into a blending opener for processing , and then fed to the carding machine for carding processing, and output to obtain a uniformly mixed fiber web; the fiber web is fed to the web-laying machine for cross-laying, and then the stacked fiber web is multi-staged by a random drafting machine. Drafting to obtain a fiber web with an interpenetrating network structure; then use the sodium sulfate aqueous solution with a concentration of 2g / L, 4g / L, 6g / L, 8g / L, 10g / L and 12g / L to treat the fiber web. Reinforced by high-pressure spunlace, the weight is 40g / m 2 Six kinds of spunlace nonwoven fabrics; the six kinds of spunlace nonwoven fabrics made by padding successively with a concentration of 30% ethanol / water mixed solution, a concentration of 50% ethanol / w...

Embodiment 3

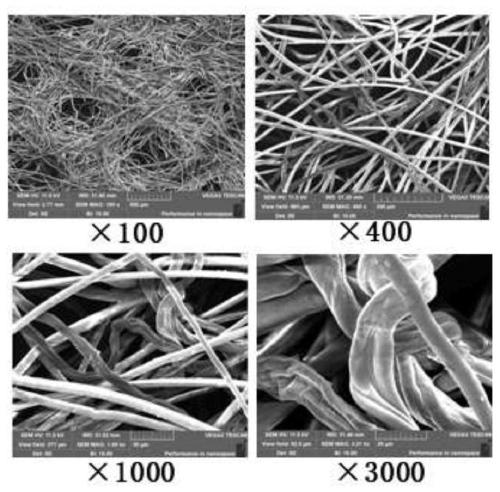

[0082] Weigh 22 kilograms of commercially available calcium alginate fibers, 23 kilograms of cupro ammonia fibers and 55 kilograms of tencel fibers, respectively pre-open the three fibers, and then mechanically blend them; finely open the blended fibers, and then feed It is fed into the mixing opener for processing, and then fed into the carding machine for carding processing, and the output is a uniformly mixed fiber web; the fiber web is fed into the web-laying machine for cross-laying, and then the laminated fiber web is processed by a random drafting machine. The web is drawn by multi-stage small multiples to obtain a fiber web with an interpenetrating network structure; the fiber web is reinforced by high-pressure hydroentanglement with a sodium sulfate aqueous solution with a concentration of 7g / L, and the grammage is 25g / m 2 The spunlaced non-woven fabrics were then cleaned in the following three ways: (1) Ultrasonic cleaning with distilled water, and then hot air drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com