Preparation method of nano magnetic material loaded mineral soil for reducing COD and heavy metals in excrement biogas slurry wastewater

A nano-magnetic material and biogas slurry wastewater technology, which is applied in the field of wastewater treatment materials, can solve the problems of slow reaction rate of zeolite and mineral soil, high energy consumption in the process of propagation and purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

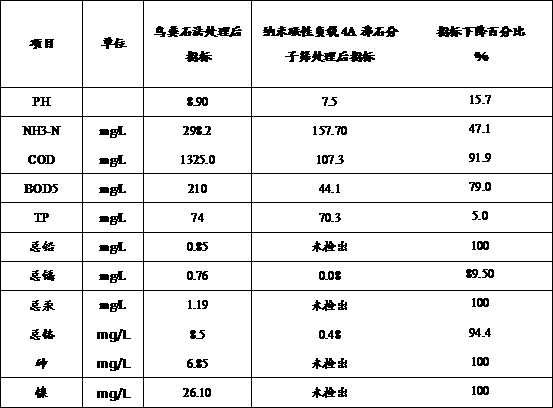

[0073] The raw water is biogas slurry produced by anaerobic digestion of breeding wastewater from a cattle farm in Yinchuan. Before the test, it was filtered with a filter cloth to remove large suspended particles. The quality of the filtered water samples is shown in Table 1-1.

[0074] Table 1-1. Test raw water quality

[0075] project unit Raw water index data pH 9.20 NH 3 -N

mg / L 2685 COD mg / L 1972 BOD5 mg / L 240 TP mg / L 101 Conductivity ms.cm -1

39.80 Turbidity NTU 56.70 total lead mg / L 13.40 Total Cadmium mg / L 1.08 total mercury mg / L 1.50 total chromium mg / L 9.10 arsenic mg / L 7.32 nickel mg / L 27.70

[0076] 1. First, filter the manure or biogas slurry, inject 1000mL of filtrate into the reaction tank, and put KH into the reaction tank 2 PO 4 , to adjust the PO in the solution 4 3- : NH 4+ =1:1 (molar ratio); put MgCl into the reaction pool ...

Embodiment 2

[0124] The raw water is biogas slurry produced by anaerobic digestion of breeding wastewater from a cattle farm in Yinchuan. Before the test, it was filtered with filter cloth to remove large suspended particles. The water quality after filtration is shown in Table 2-1.

[0125] Table 2-1 Test raw water quality

[0126] project unit Raw water index data pH 9.20 NH 3 -N

mg / L 2685 COD mg / L 1972 BOD5 mg / L 240 TP mg / L 101 Conductivity ms.cm -1

39.80 Turbidity NTU 56.70 total lead mg / L 13.40 Total Cadmium mg / L 1.08 total mercury mg / L 1.50 total chromium mg / L 9.10 arsenic mg / L 7.32 nickel mg / L 27.70

[0127] 1. First, filter the manure or biogas slurry, inject 1000mL of filtrate into the reaction tank, and put KH into the reaction tank 2 PO 4 , to adjust the PO in the solution 4 3- : NH 4+ =1.25:1 (molar ratio); put MgCl into the reaction pool 2 6H ...

Embodiment 3

[0175] The raw water is manure from Lingwu cattle farm. Before the test, it was filtered with filter cloth to remove large particles of suspended matter. The quality of filtered water samples is shown in Table 3-1.

[0176] Table 3-1 Test raw water quality

[0177] project unit Raw water index data pH 9.60 NH3-N mg / L 3367 COD mg / L 2564 BOD5 mg / L 320 TP mg / L 167 Conductivity ms.cm -1

40.11 Turbidity NTU 57.30 total lead mg / L 11.50 Total Cadmium mg / L 1.12 total mercury mg / L 1.16 total chromium mg / L 8.90 arsenic mg / L 7.33 nickel mg / L 26.5

[0178] 1. First, filter the manure or biogas slurry, inject 1000mL of filtrate into the reaction tank, and put KH into the reaction tank 2 PO 4 , to adjust the PO in the solution 4 3- : NH 4+ =1.2:1 (molar ratio); put MgCl into the reaction pool 2 6H 2 O, adjust the Mg in the solution 2+ : NH 4+ =1.05:1 (molar r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap