Polycrystalline B4C-SiC double-layer composite material and preparation method thereof

A composite material and double-layer technology, which is applied in the field of polycrystalline B4C—SiC double-layer composite material and its preparation, can solve the problems of low production cost, low fracture toughness, boron oxide gas phase loss, etc., and achieve large-scale industrialization Effect of production, high temperature stability mechanical properties, uniform distribution of grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

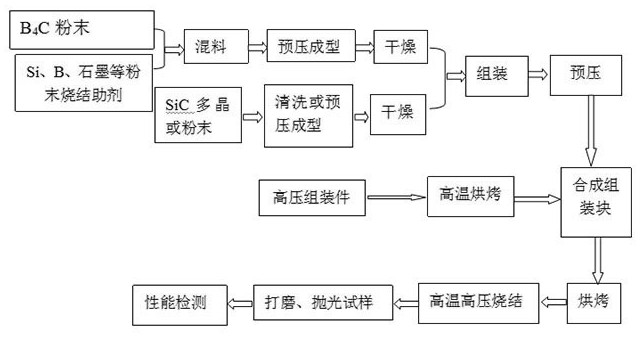

Method used

Image

Examples

Embodiment 1

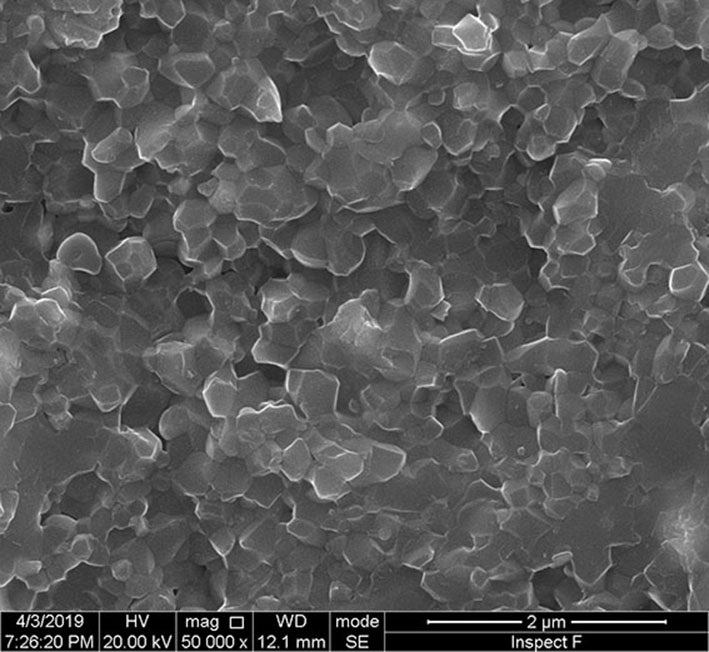

[0034] a. Raw material processing and testing: Take 30 g of polycrystalline SiC bulk material with a purity of 98% and an average grain size of 1 μm; take polycrystalline B with a purity of 98% and an average grain size of 7 μm 4 C powder 67 g; polycrystalline SiC bulk material with a volume fraction of 6% Si was added as a sintering aid, treated with 100 ml of absolute ethanol, poured out the waste liquid, and dried in an oven at 120 °C; polycrystalline B 4 Add B with a volume fraction of 3% to C powder as a sintering aid, treat it with 60 ml of absolute ethanol, pour out the waste liquid, and dry it in an oven at 120 °C. After drying, the polycrystalline B 4 Add 60 ml of deionized water to the C powder and the polycrystalline SiC block, and pre-press them respectively, and dry the formed samples in a vacuum drying oven;

[0035]b. Assembling the sintering unit: processing the metal inclusions used to wrap the raw materials, grinding and polishing, then degreasing, ultrasonic...

Embodiment 2

[0040] a. Raw material processing and testing: Take 44 g of polycrystalline SiC bulk material with a purity of 98% and an average grain size of 500 nm; take polycrystalline B with a purity of 99% and an average grain size of 20 μm 4 C powder 86 g, polycrystalline SiC bulk material was added Si with a volume fraction of 2% as a sintering aid, treated with 100 ml of absolute ethanol, poured out the waste liquid, and dried in an oven at 120 °C; polycrystalline B 4 C powder was treated with 150 ml of absolute ethanol, and after pouring out the waste liquid, it was dried in an oven at 120 °C, and the dried polycrystalline B 4 Add 80 ml of deionized water to C powder and polycrystalline SiC bulk material respectively and pre-press them respectively, and dry the formed samples in a vacuum drying oven;

[0041] B, this step is identical with the step b in embodiment 1;

[0042] c. High-temperature and high-pressure sintering: Use a six-sided top press for high-temperature and high-pr...

Embodiment 3

[0046] a. Raw material processing and testing: take 115 g of polycrystalline SiC bulk material with a purity of 99% and an average grain size of 10 μm, and polycrystalline B with a purity of 99% and an average grain size of 500 nm 4 C powder 110 g, the polycrystalline SiC block was treated with 210 ml of absolute ethanol, and the waste liquid was poured out, and then dried in an oven at 120 °C; polycrystalline B 4 C powder was treated with 200 ml of absolute ethanol, and after pouring out the waste liquid, it was dried in an oven at 120 °C, and the dried polycrystalline B 4 Add 120 ml of deionized water to C powder and polycrystalline SiC bulk material respectively and pre-press them respectively, and dry the formed samples in a vacuum drying oven;

[0047] B, this step is identical with the step b in embodiment 1;

[0048] c. High-temperature and high-pressure sintering: Use a six-sided top press for high-temperature and high-pressure sintering. After reaching the set pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com