Environment-friendly microbial composite paraffin remover and inhibitor for oil well

An environmentally friendly and microbial technology, applied in wellbore/well components, drilling composition, earthwork drilling and mining, etc., can solve the problem of flammability and explosion of wax remover, great damage to the environment and human body, and weak anti-scouring ability and other problems, to achieve the effects of prolonged action period, fast wax melting rate and strong erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

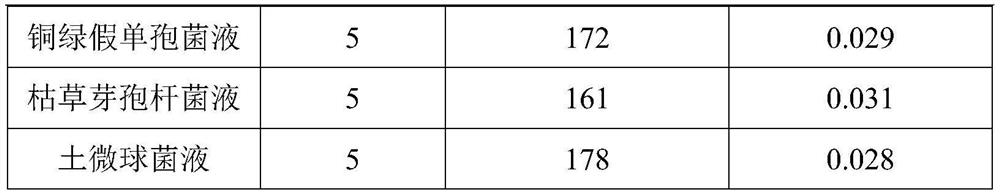

[0023] In this embodiment, the growth conditions of the selected Pseudomonas aeruginosa, Bacillus subtilis and Micrococcus terreus in the crude oil were determined.

[0024] Take three 150mL Erlenmeyer flasks, numbered 1#, 2#, and 3#. After sterilization, add 3g of the crude oil sample in the Jing’an operation area of Changqing Oilfield and 60mL of the nutrient solution for the strains, and insert them into the aeruginosa fake sheets in turn. Bacillus subtilis fermentation broth 1mL, Bacillus subtilis fermentation broth 2mL, Micrococcus terreus fermentation broth 1mL, placed at 30°C under aerobic conditions for constant temperature culture for 5 days, and the growth of each strain in the bacterial suspension was counted by the hemocytometer method . The measurement results are shown in Table 1.

[0025] Table 1, the growth of Pseudomonas aeruginosa, Bacillus subtilis and Micrococcus terreus in high-wax crude oil

[0026] Numbering Microorganism name Number of ...

Embodiment 2

[0029] This example provides a preferred oil well environment-friendly microbial composite paraffin remover.

[0030] The culture and fermentation broths of Pseudomonas aeruginosa, Bacillus subtilis, and Micrococcus terreus were respectively taken, and mixed at a volume ratio of 1:2:1 to obtain a waxy mixed bacterial liquid.

[0031] Weigh 90kg deionized water, 20kg sweet potato powder, 1kg liquid paraffin, 1kg distiller's grains, 1kg agar, 1kgNaCl, 1kgNH 4 Cl, 2kgKH 2 PO4, 1kgCaCl 2 , 1kgNa 2 SO 4 , mixed, and prepared into a strain nutrient solution.

[0032] Compounding 15kg of the above-mentioned paraffinophilic mixed bacterial solution, 15kg of bacterial strain nutrient solution, 5kg of oleic acid amide betaine FDCH-1, 5kg of polyoxyethylene octylphenol ether-10, and 2kg of ethylene glycol monobutyl ether to obtain the described Oil well environment-friendly microbial compound paraffin remover.

[0033] An effect evaluation test was carried out on the environment-fr...

Embodiment 3

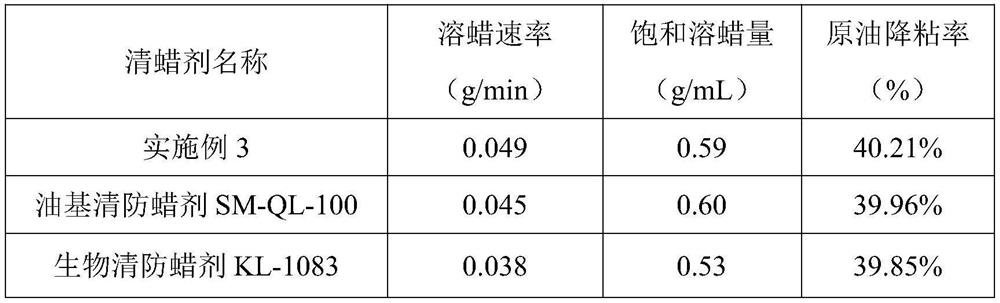

[0036] On the basis of Example 2, this example provides a preferred oil well environment-friendly microbial composite paraffin remover.

[0037] The components and contents of the strain nutrient solution are: 100kg deionized water, 35kg sweet potato powder, 5kg liquid paraffin, 4kg distiller's grains, 3kg agar, 2kgNaCl, 2kgNH 4 Cl, 7kgKH 2 PO4, 2kgCaCl 2 , 2kgNa2 SO 4 .

[0038] Compound 20kg of the wax-loving mixed bacteria solution mentioned above, 60kg of the bacteria nutrient solution, 9kg of fluorocarbon surfactant FC-3B, 9kg of SP80, and 4kg of ethylene glycol monobutyl ether to obtain the oil well environment-friendly microbial compound wax-removing agent.

[0039] The oil well environment-friendly microbial compound paraffin remover was subjected to an effect evaluation test. Take 5g of solid paraffin from X oil well in Changqing Oilfield, soak it in 15mL of the compound paraffin remover, keep the water bath at a constant temperature of 45±1°C, observe and record ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com