Composite solid electrolyte material and preparation method thereof

A solid electrolyte and electrolyte technology, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of low ionic conductivity, low interface impedance, lithium salt dissociation ability and poor chain segment movement, and achieve improved Effects of electrochemical window, improvement of room temperature conductivity, and increase of ion transfer number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

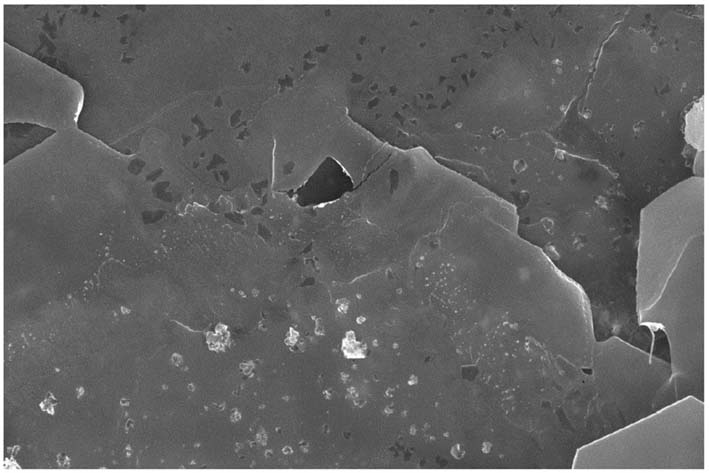

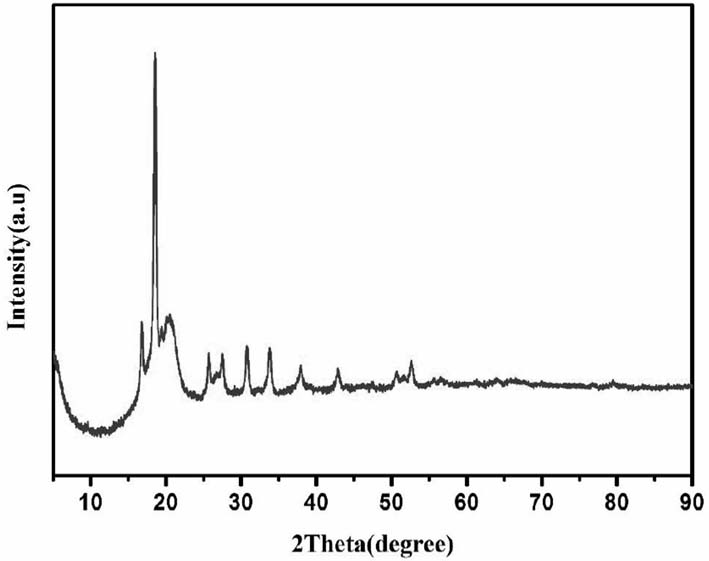

Image

Examples

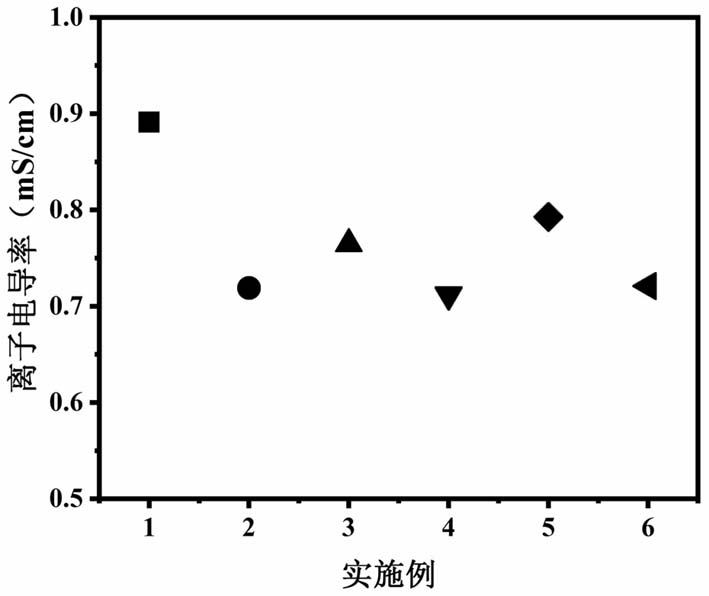

Embodiment 1

[0032] 1. Preparation of solid electrolyte:

[0033] 1. Polyvinylidene fluoride (PVDF), Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO), succinonitrile (SN) and lithium bisfluorosulfonimide (LIFSI) were dried.

[0034] 2. Weigh 20.622g of PVDF and dissolve it in N,N-dimethylacetamide (DMAC) solvent, and stir with an electric mixer for 2 hours to obtain a uniform glue solution. The total concentration of PVDF in DMAC is 12%.

[0035] 3. Weigh 4.537g of SN and 2.063g of oxide electrolyte LLZTO and add them to the above glue, and stir for 1 hour under an electric mixer to obtain a mixed suspension glue.

[0036] 4. Finally, weigh 7.273g of LiFSI and add it, stir under the electric mixer for 1h, pour the suspended glue into a 500mL ball mill jar, mix and ball mill for 12h to obtain a uniform solid electrolyte glue.

[0037] 5. The solid electrolyte glue is vacuumized in the vacuum box for 0.5h, and the obtained glue is cast into the mold by casting method.

[0038] 6. Put the mold i...

Embodiment 2

[0045] 1. Preparation:

[0046] Polytetrafluoroethylene (PTFE), Li 6.4La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO), succinonitrile (SN) and lithium bis(trifluoromethylsulfonyl)imide (LITFSI) were dried for 12 hours, 22.364g of PTFE was weighed and dissolved in N-methylpyrrolidone (NMP) solvent, and electric mixer Stir for 2 hours to obtain a uniform glue solution. The total concentration of PTFE in the NMP solution is 15%, then weigh 5.964g of SN and 3.356g of oxide electrolyte LLZTO and add them to the above glue solution, and stir for 1 hour under an electric mixer to obtain a mixed solution. Suspend the glue, and finally weigh 7.455g LiTFSI and add it, stir under the electric mixer for 1h, pour the suspension into a 500mL ball mill jar, mix and ball mill for 12h to obtain a uniform solid electrolyte glue. The solid electrolyte glue was evacuated in the vacuum box for 0.5h, and the obtained glue was cast into the mold by casting method. Put the mold into a vacuum drying oven and dr...

Embodiment 3

[0051] 1. Preparation:

[0052] Polyacrylonitrile (PAN), Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO), succinonitrile (SN) and lithium bis(trifluoromethylsulfonyl)imide (LITFSI) were dried, and 21.542g of PAN was weighed and dissolved in N,N-dimethylformamide (DMF) In the solution, stir with an electric mixer for 2 hours to obtain a uniform glue solution. The total concentration of PAN in DMF is 10%, then weigh 5.745g of SN and 5.756g of oxide electrolyte LLZTO and add them to the above glue solution, and stir with an electric mixer 1h to get the mixed suspension glue, finally weigh and add 7.180g LiTFSI, stir under the electric mixer for 1h, pour the suspension glue into a 500mL ball mill jar and mix ball mill for 12h to get a uniform solid electrolyte glue. The solid electrolyte glue was evacuated in the vacuum box for 0.5h, and the obtained glue was cast into the mold by casting method. Put the mold into a vacuum drying oven and dry it in vacuum at 60° C. for 24 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com